Efficient long-acting low-wind-resistance air purification material for air conditioners

An air purification material and high-efficiency technology, applied in the field of air purification, can solve the problems of not fundamentally eliminating pollution, increasing energy consumption of air conditioners, and harming human health, and achieving the effects of rapid adsorption and enrichment, small wind resistance, and promotion of absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cuboid high specific surface honeycomb activated carbon (45 mm*33 mm*30 mm), square hole density is 120 holes per square inch, specific surface area is 1300 m 2 / g, the compressive strength is 9 Mpa, and the saturated water absorption rate is 70%

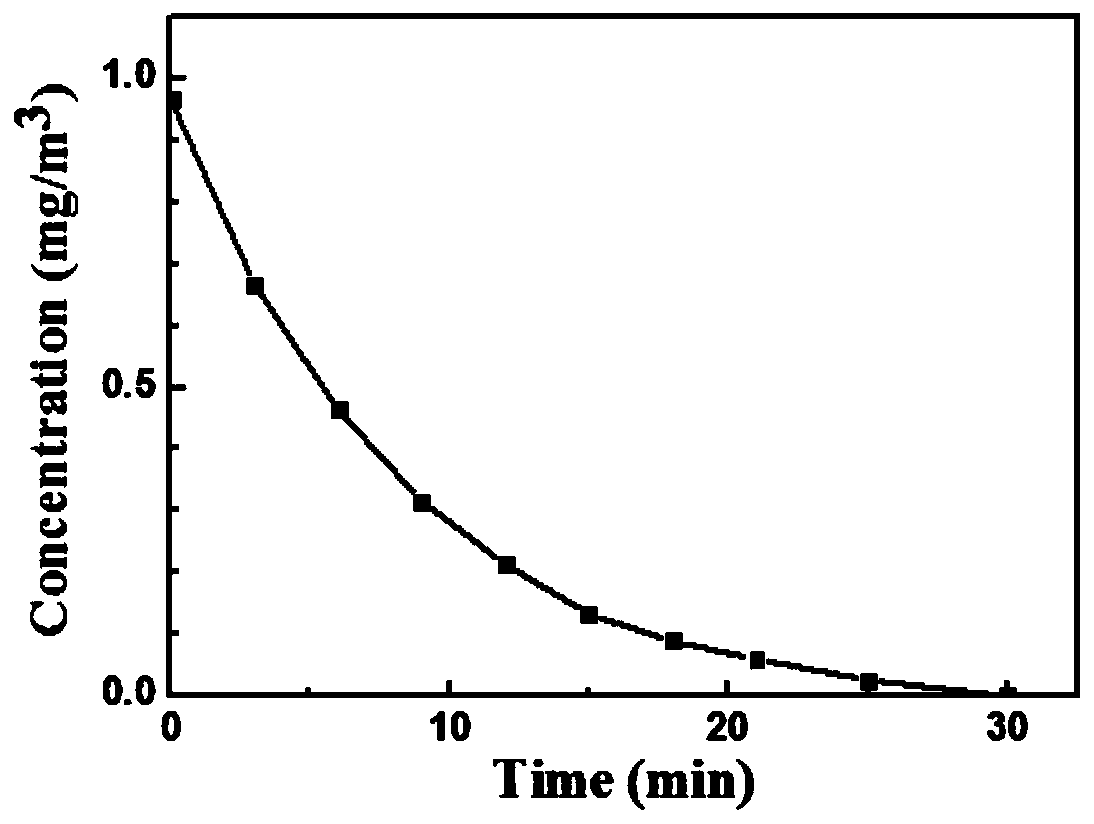

[0027] The above honeycomb module was loaded with 0.5wt% ethyl acetoacetate, 0.1wt% sodium bisulfite, 0.03wt% ferrous chloride, 0.02wt% α-cyclodextrin, 0.01wt% fatty alcohol polyoxyethylene sulfonate and 0.01 After adding wt% sodium dichloroisocyanurate, take 76 pieces and assemble them into a frame filter element and install it on the wall-mounted air conditioner indoor unit (if attached figure 1 shown). 30 m specified in GB / T 18801-2015 3 The formaldehyde purification experiment was carried out in the test cabin, the experimental temperature was 25.3 ℃, the relative humidity was 48%, and the initial concentration of formaldehyde was 0.967 mg / m 3 , the rated air volume of the air conditioner is 420 m 3 / h, the test resul...

Embodiment 2

[0029] Cuboid high specific surface honeycomb activated carbon (45 mm*33mm*30 mm), the circular hole density is 90 holes per square inch, and the specific surface area is 921 m 2 / g, the compressive strength is 5.6 Mpa, and the saturated water absorption rate is 62%.

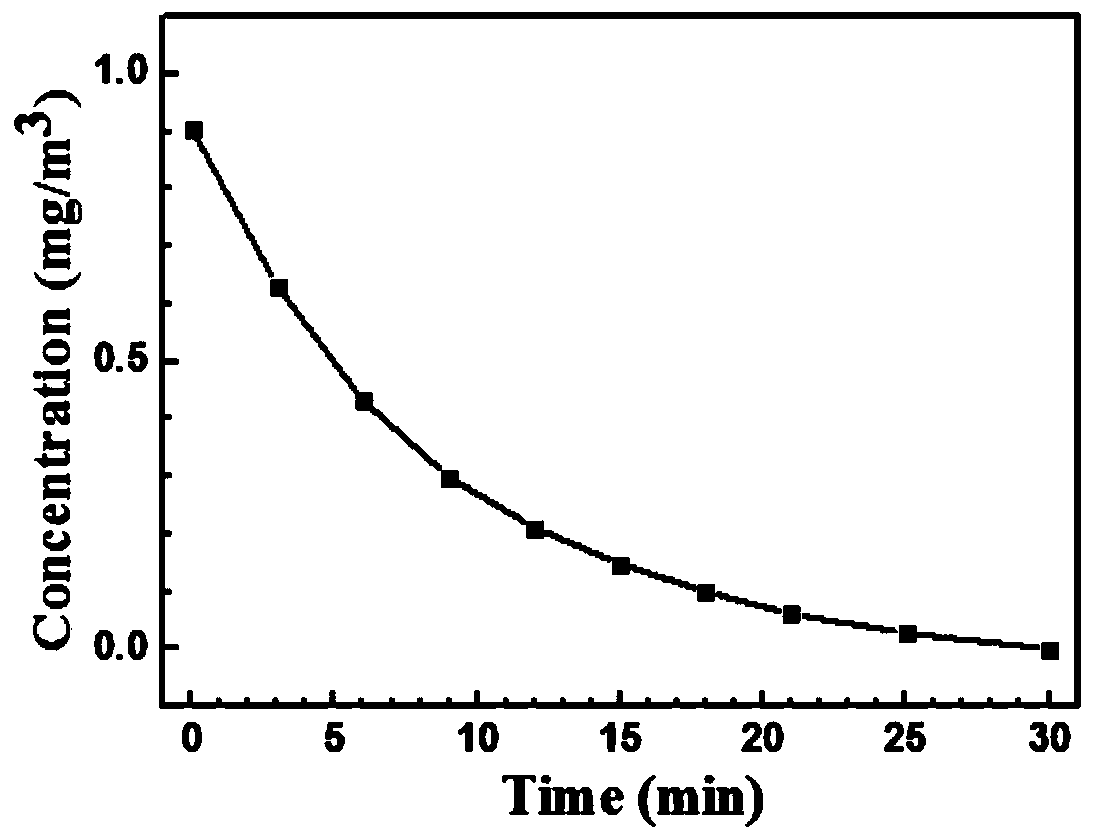

[0030] The above honeycomb module is loaded with 0.3wt% polyvinyl alcohol, 0.2wt% potassium bisulfite, 0.05wt% sodium bicarbonate, 0.01wt% β-cyclodextrin, 0.02wt% fatty alcohol polyoxyethylene sulfonate and 0.02wt% After dichloroisocyanuric acid, take 76 pieces and assemble them into a frame filter element and install it on the wall-mounted air conditioner indoor unit. 30 m specified in GB / T 18801-2015 3 The formaldehyde purification experiment was carried out in the test cabin, the experimental temperature was 24.5 ℃, the relative humidity was 48%, and the initial concentration of formaldehyde was 0.905 mg / m 3 , the rated air volume of the air conditioner is 420 m 3 / h, the test results show that the purific...

Embodiment 3

[0032] Cuboid high specific surface honeycomb activated carbon (45 mm*33mm*30 mm), the square hole density is 90 holes per square inch, and the specific surface area is 689 m 2 / g, the compressive strength is 8.7 Mpa, and the saturated water absorption rate is 70%.

[0033] The above honeycomb module is loaded with 0.3wt% polyvinyl alcohol, 0.2wt% potassium bisulfite, 0.1wt% ethyl acetoacetate, 0.05wt% sodium bicarbonate, 0.01wt% ferrous sulfate, 0.01wt% fatty alcohol polyoxyethylene ether After mixing with 0.01wt% dichloroisocyanuric acid, take 76 pieces and assemble them into a frame filter element and install it on the wall-mounted air conditioner indoor unit. 30m specified in GB / T 18801-2015 3 The formaldehyde purification experiment was carried out in the test cabin, the experimental temperature was 25.2 ℃, the relative humidity was 51%, and the initial concentration of formaldehyde was 1.012 mg / m 3 , the rated air volume of the air conditioner is 420 m 3 / h, the test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com