Preparation method of cellosilk-graphene-platinum ternary composite catalyst

A ternary composite and graphene technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy loss, achieve high affinity, ensure uniformity, and be easy to solve churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method utilizing coconut water to realize graphene oxide reduction and platinum immobilization, comprising the following steps:

[0028] (1) Take 100mL of coconut water, add Gluconacetobacter, culture at 30°C for 5 days, and fiber filaments will be produced in the coconut water.

[0029] (2) Prepare 20mL of a mixed solution containing 1wt% graphene oxide and 0.2wt% chloroplatinic acid.

[0030] (3) Drop the mixed solution obtained in step (2) into the product of step 1, and continue culturing at 30° C. for 5 days, so that the graphene oxide and chloroplatinic acid are mixed into the fiber filaments.

[0031] (4) Heating the mixture obtained in step (2) to 90° C. and reacting for 24 hours to reduce the graphene oxide to graphene, and at the same time, chloroplatinic acid is reduced to metal platinum and immobilized on the graphene.

[0032] (5) cleaning step (4) gained solid product, obtains fiber silk-graphene-platinum ternary composite catalyst; Gained ternary compo...

Embodiment 2

[0054] The fiber filament-graphene-platinum ternary composite catalyst obtained in embodiment 1 is used to carry out the catalytic oxidation degradation test for organic pollutants, specifically as follows:

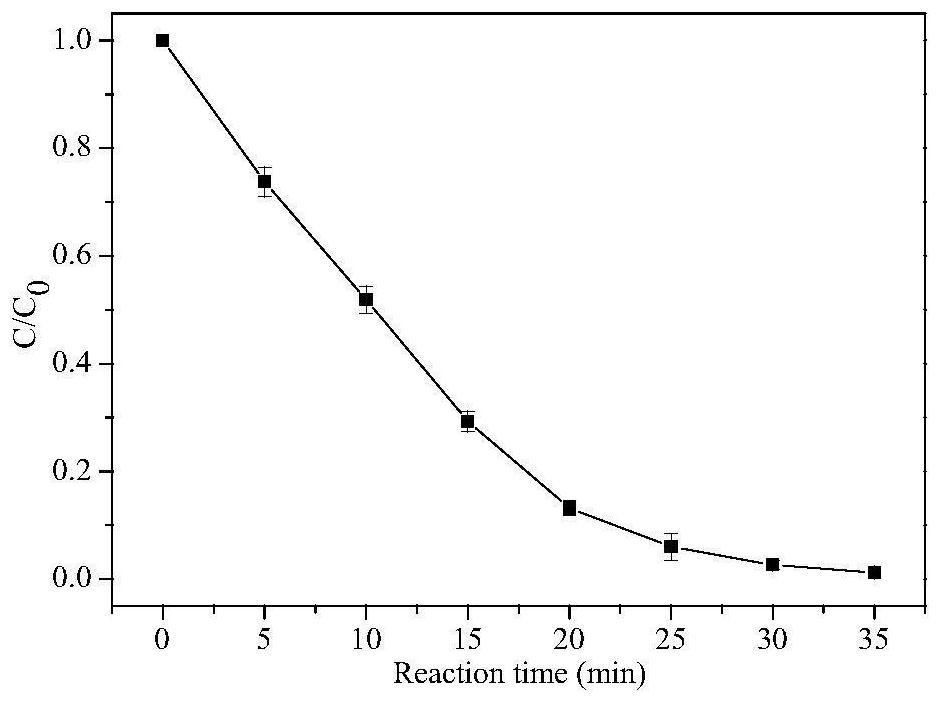

[0055] Get 1.00mg by the obtained fiber silk-graphene-platinum ternary composite catalyst of embodiment 1, apply it to the catalytic oxidative degradation of organic pollutant, experiment object is active red 2 (CAS number: 17804-49-8) dye solution . The specific experimental conditions are: the initial concentration of the dye solution is 1×10 -4 mol / L, dye solution volume 10mL, adjust the pH value of dye solution=3, H 2 o 2 Oxidant concentration 5×10 -3 mol / L, the reaction temperature is 50°C. After 35 minutes of reaction, the concentration of the dye solution decreased by 98.81%. For specific experimental results, see figure 1 .

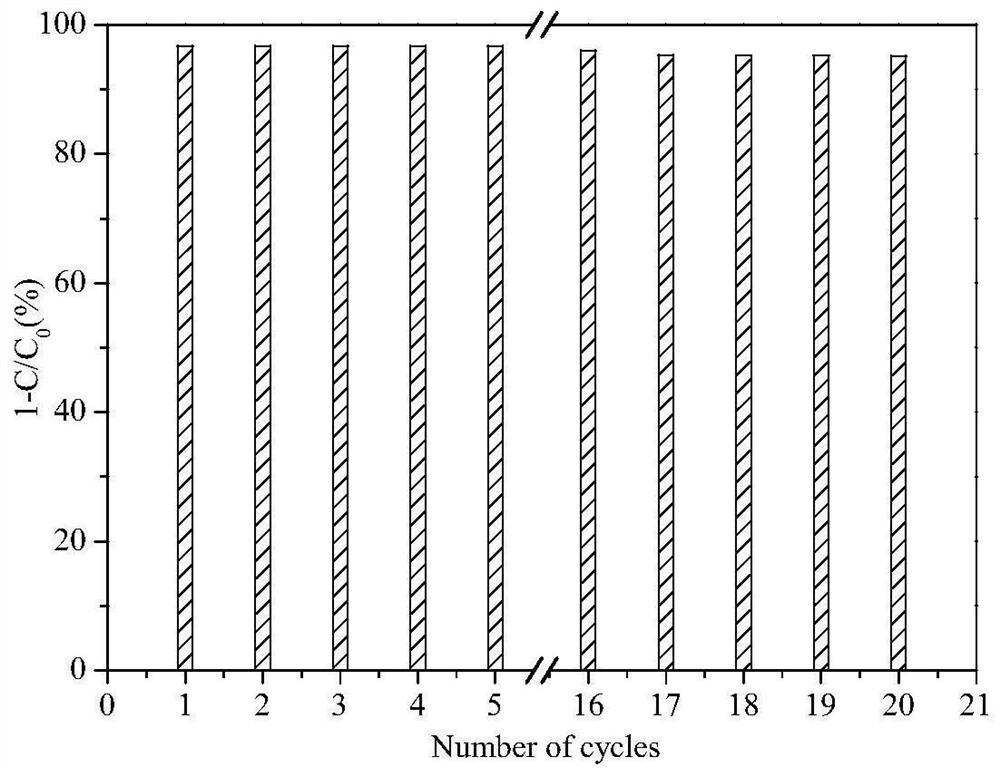

[0056] In order to investigate the reusability of the obtained fiber silk-graphene-platinum ternary composite catalyst, the fiber silk...

Embodiment 3

[0089] A method utilizing coconut water to realize graphene oxide reduction and platinum immobilization, comprising the following steps:

[0090] (1) Take 100mL of coconut water, add Gluconacetobacter, culture at 30°C for 5 days, and fiber filaments will be produced in the coconut water.

[0091] (2) Prepare 20mL of a mixed solution containing 1wt% graphene oxide and 2wt% chloroplatinic acid.

[0092] (3) Drop the mixed solution obtained in step (2) into the product of step 1, and continue culturing at 30° C. for 5 days, so that the graphene oxide and chloroplatinic acid are mixed into the fiber filaments.

[0093] (4) Heating the mixture obtained in step (2) to 90° C. and reacting for 24 hours to reduce the graphene oxide to graphene, and at the same time, the chloroplatinic acid is reduced to metal platinum and immobilized on the graphene.

[0094] (5) cleaning step (4) gained solid product, obtains fiber silk-graphene-platinum ternary composite catalyst; Gained ternary com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com