Manufacturing technology for optimized cobalt-base deformed high-temperature alloy forged bar

A technology for deforming superalloys and manufacturing processes, which is applied in the field of superalloy forging processing, can solve problems such as the aggregation of carbide strips, and achieve the effect of improving the uniformity of the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

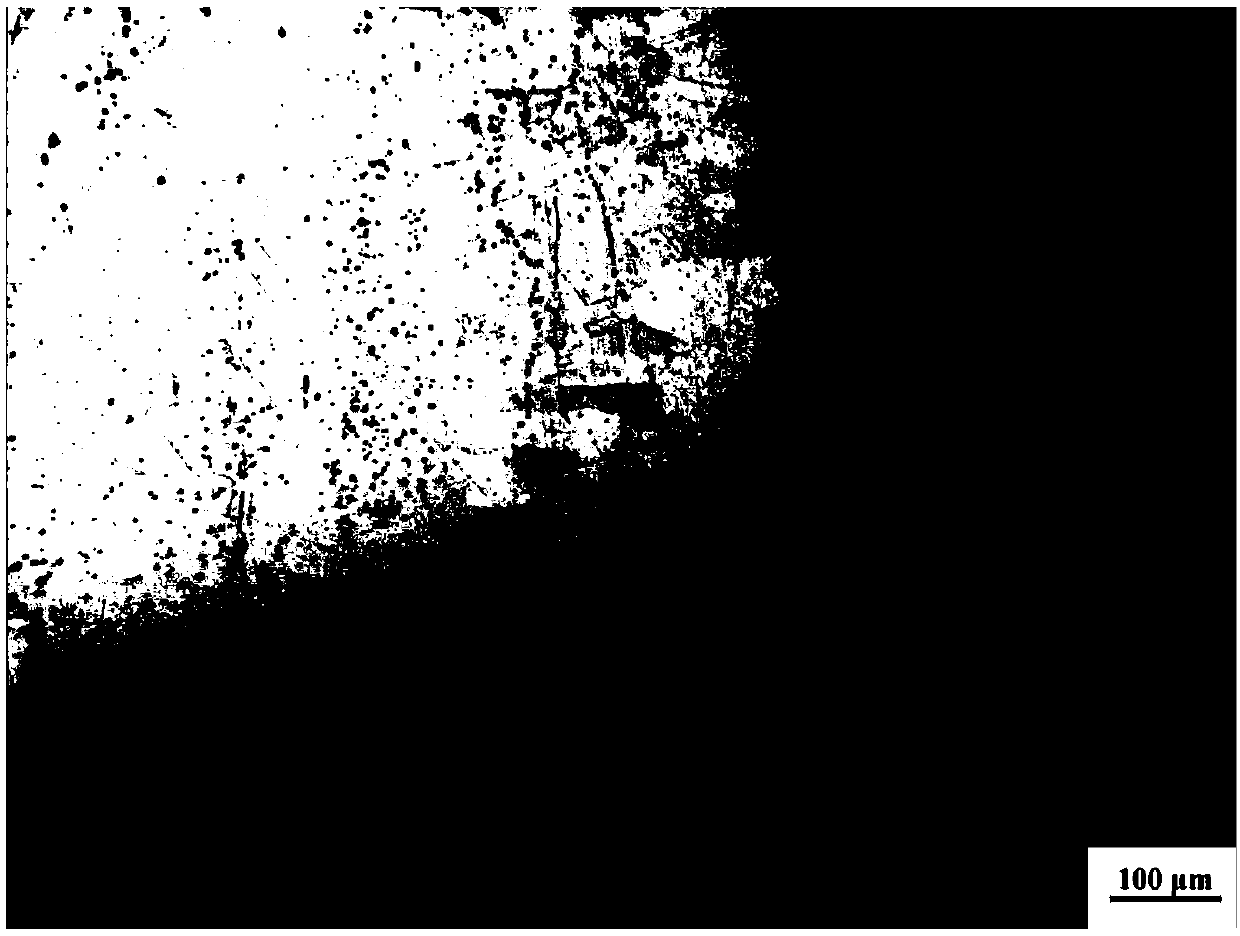

Embodiment 1

[0028] GH5188 alloy forged rod finished product, specification Φ180mm;

[0029] The ingot shape is Φ480mm, the heating temperature of the steel ingot is 1160°C, and the holding time is 3h;

[0030] Fast forging first fire forging: heating temperature 1160°C, single hammer reduction 30mm, forging to Φ450mm, deformation 12%;

[0031] Intermediate billet heating: the intermediate billet Φ450mm is returned to the furnace, the heating temperature is 1160°C, and the refiring time is 2h;

[0032] Fast forging intermediate heat forging: Φ450mm intermediate billet undergoes 1 upsetting + drawing, pier thickness 200mm, drawing length to Φ450mm, forging heating temperature 1160°C, deformation 44%;

[0033] Intermediate billet heating: intermediate billet Φ450mm, reheating temperature 1160°C, refiring time 2h;

[0034] Fast forging intermediate fire secondary forging: Φ450mm intermediate billet is drawn up to 350mm square, the forging heating temperature is 1160°C, and the deformation i...

Embodiment 2

[0041] GH5188 alloy forged rod finished product, specification Φ250mm;

[0042] The ingot shape is Φ480mm, the heating temperature of the steel ingot is 1170°C, and the holding time is 2h.

[0043] Fast forging first fire forging: heating temperature 1170℃, single hammer reduction 30mm, forging to Φ450mm, deformation 12%;

[0044] Intermediate billet heating: the intermediate billet Φ450mm is returned to the furnace, the heating temperature is 1170°C, and the refiring time is 2.5h;

[0045] Fast forging intermediate heat forging: Φ450mm intermediate billet undergoes 2 times of upsetting + elongation, pier thickness 200mm, elongation to Φ450mm, forging heating temperature 1170°C, deformation 44%;

[0046] Intermediate billet heating: intermediate billet Φ450mm, reheating temperature 1170°C, refiring time 2.5h;

[0047] Fast forging and last fire forging: the billet is elongated in one direction, the single hammer reduction is 50mm, the elongation is Φ330mm, the forging heatin...

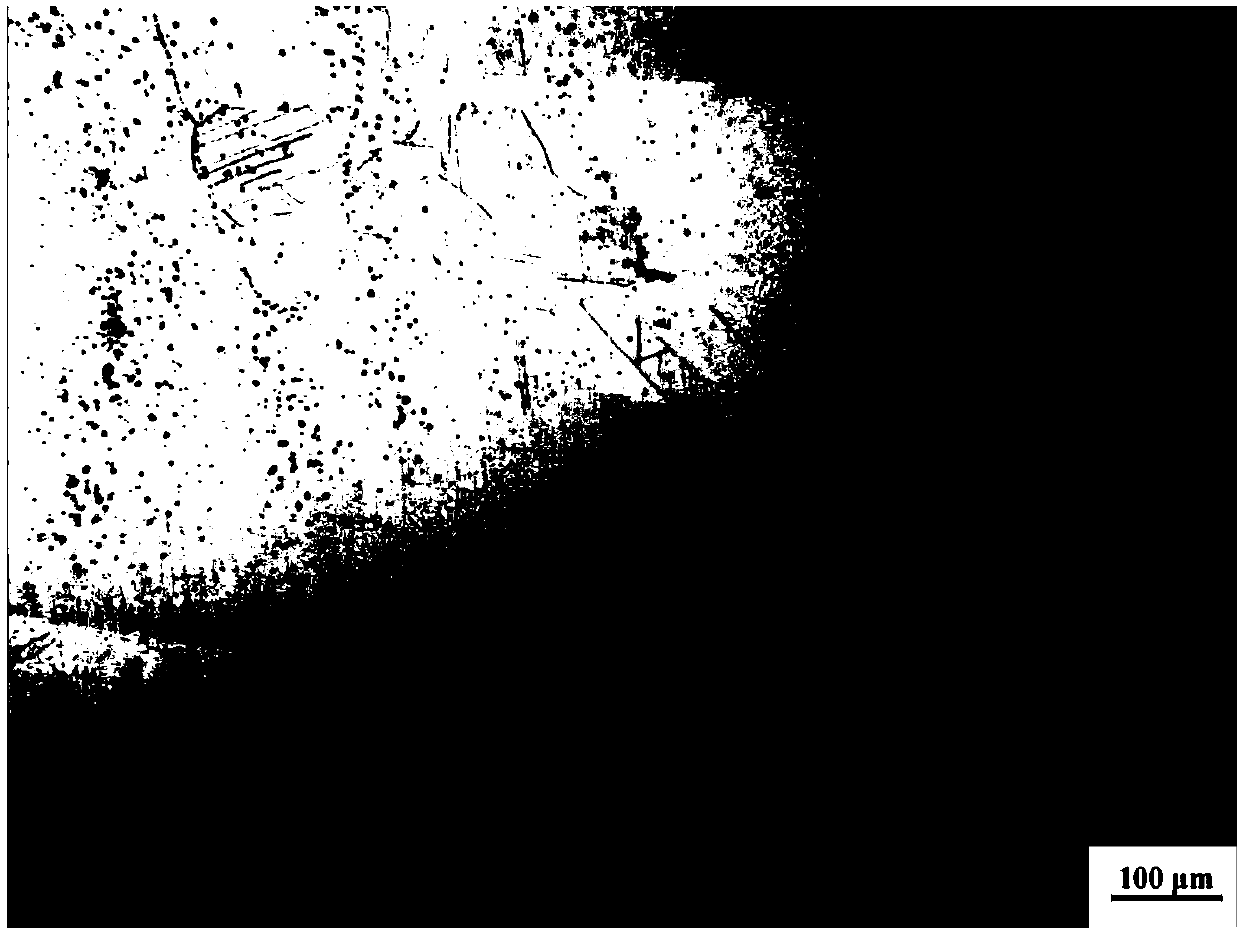

Embodiment 3

[0052] GH5188 alloy forged rod finished product, specification Φ300mm;

[0053] The ingot shape used is Φ480mm, the actual ingot heating temperature is 1150°C, and the holding time is 3h.

[0054] Fast forging first fire forging: heating temperature 1150℃, single hammer reduction 30mm, forging to Φ450mm, deformation 12%;

[0055] Intermediate billet heating: the intermediate billet Φ450mm is returned to the furnace, the heating temperature is 1150°C, and the refiring time is 3h;

[0056] Fast forging intermediate fire secondary forging: Φ450mm intermediate billet undergoes 3 times of upsetting + drawing, pier thickness 200mm, drawing length to 450mm square, forging heating temperature 1150°C, deformation amount 45%;

[0057] Intermediate billet heating: intermediate billet Φ450mm, reheating temperature 1150°C, refiring time 3h;

[0058] Fast forging and last fire forging: the billet is elongated in one direction, the single hammer reduction is 50mm, the elongation is Φ360mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com