Epoxy mono-component structural adhesive and preparation method thereof

A technology of structural glue and epoxy sheet, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of difficulty in comprehensive performance improvement, complex and multi-faceted influence of comprehensive performance, and inability to improve comprehensive performance, etc., to achieve Effect of high T-peel strength and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

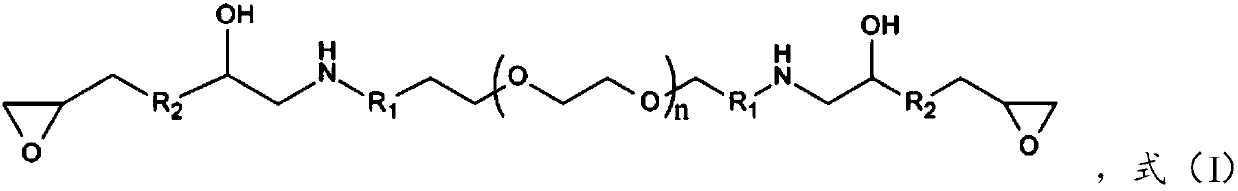

Method used

Image

Examples

preparation example Construction

[0078] The present invention also provides a preparation method of the above-mentioned epoxy one-component structural adhesive, comprising the following steps:

[0079] Add active diluent, core-shell rubber, resin-modified nitrile rubber, and polyurethane toughener to the epoxy resin and disperse evenly, then add water-absorbing agent, filler, thixotropic agent, curing agent and curing accelerator to mix and stir, vacuum Degassing to obtain epoxy one-component structural adhesive.

[0080] When the formulation of the present invention is designed, under the condition that the comprehensive properties (such as shear strength and T-peel strength) can meet the basic requirements, the components participating in the curing cannot reach the optimal curing conditions, and deliberately make it deviate from the ideal reaction ratio. Improvements in the type of damage are thereby achieved.

[0081] In the present invention, by controlling the ratio of the curing accelerator and the cu...

Embodiment 1

[0084] 1. See Table 1 for the list of basic ingredients in the following examples

[0085] Table 1

[0086]

[0087]

[0088]In Table 1, the specific types of raw materials are as follows:

[0089] Mixed epoxy resin: liquid epoxy resin and solid epoxy resin are mixed according to the mass ratio of 3:1, and melted at 95-100°C; the solid resin is D.E.R.671 epoxy resin (Dow Chemical Co., Ltd.); liquid resin BE501H Epoxy resin, Changchun Chemical (Jiangsu) Co., Ltd.

[0090] Core-shell rubber: MX154 core-shell rubber, composed of rubber particles dispersed in epoxy resin (wherein the core-shell particle size is 25-200nm, and the mass fraction of core-shell particles is 40%), Japan Kaneka Company;

[0091] Resin-modified nitrile rubber: Hypro-861340 epoxy resin-modified liquid nitrile rubber, CVC Thermoset Specialties of the United States (wherein the mass fraction of core-shell particles is 40%, and the mass fraction of epoxy resin is 60%);

[0092] The active diluent is:...

Embodiment 2

[0112] According to the specific selection of components in the formula in Example 1, as well as the preparation method and test method, the preparation of the epoxy one-component structural adhesives in Examples D1 to D4 is carried out, see Table 3 for details

[0113] table 3

[0114] Element

[0115] Discussion of Table 3: On the basis of optimizing the relative content of accelerator / curing agent, the interface failure types of embodiment D1-D4 / C2 are cohesive failure, and T-peel strength and shear strength are maintained at a relatively high performance level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com