Mixing device for engine tail gas aftertreatment system

A tail gas post-treatment and mixing device technology, which is applied to exhaust devices, engine components, machines/engines, etc., can solve the problems of urea and exhaust gas mixing uniformity, and achieve good mixing uniformity and high gas flow velocity distribution uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

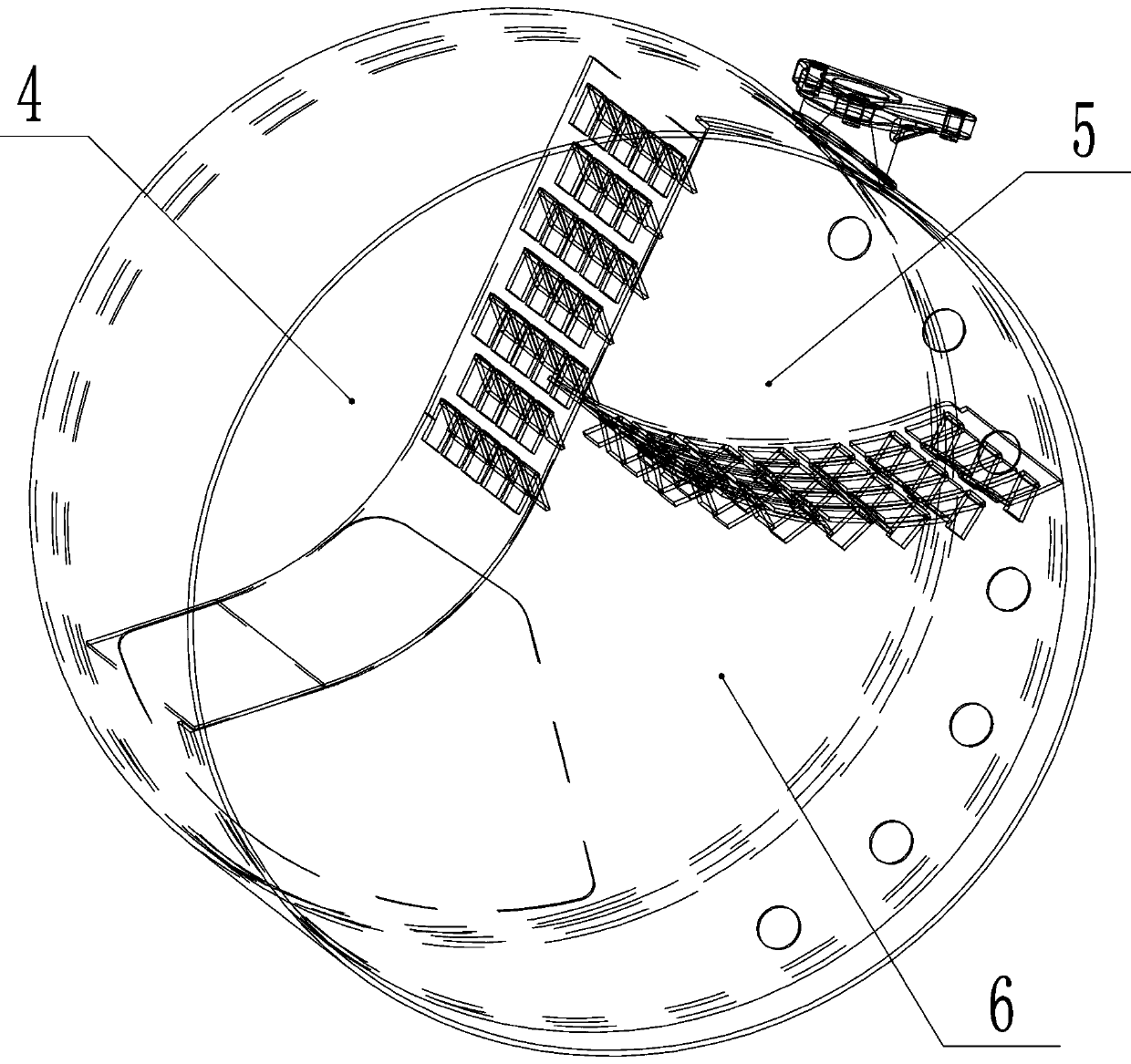

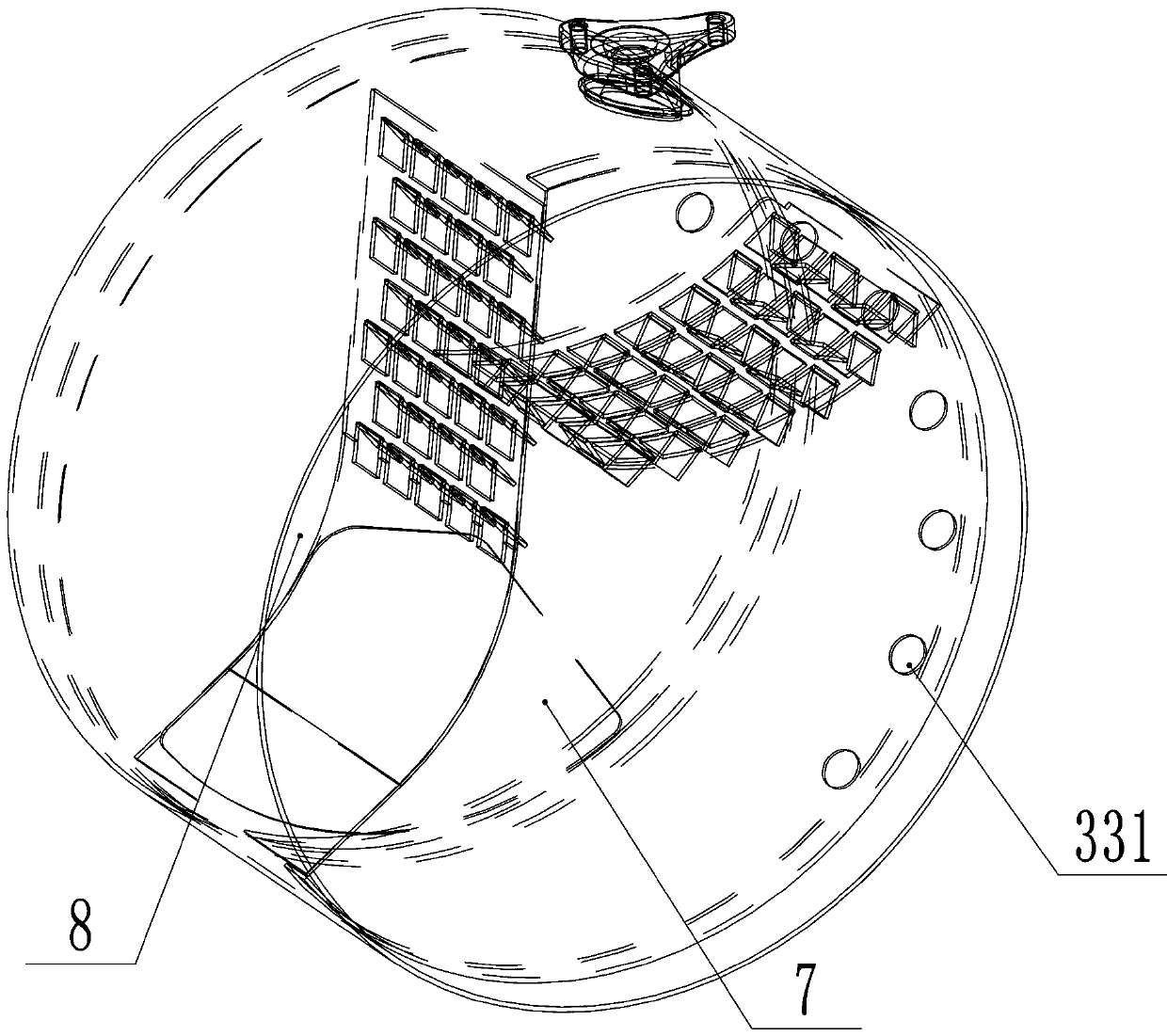

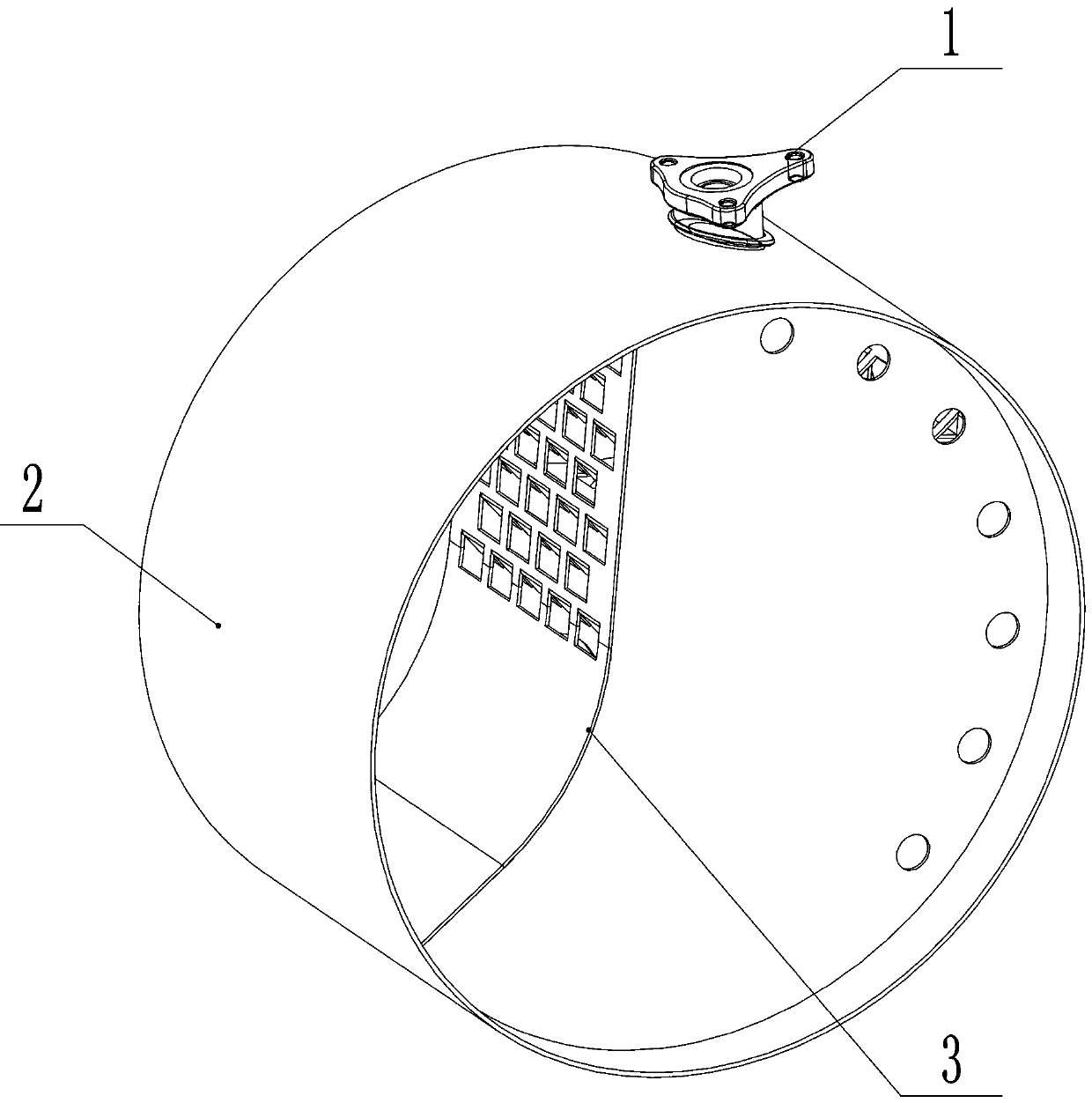

[0033] Such as Figure 1-10 As shown, the present invention includes a shell 2 and an inner assembly 3 thereof; The first deflector 31 and the second deflector 32; the first deflector 31 and the second deflector 32 form a "human" shape, and the second deflector 32 is located below the first deflector 31, thus the first deflector A deflector 31 , a second deflector 32 , a front baffle 33 and a rear baffle 34 constitute three spaces.

[0034] The shell 2 is located on the outer periphery between the front baffle 33 and the rear baffle 34 ; the first deflector 31 and the second deflector 32 are located inside the shell 2 .

[0035] A urea inlet 1 is provided at the upper casing 2 between the first deflector 31 and the second deflector 32; the urea inlet 1 is connected to the urea nozzle, and the urea nozzle is connected to the casing 2 through the urea nozzle seat .

[0036] The first deflector 31 and the second deflector 32 are respectively provided with one or more blades, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com