Device and method for accurately positioning tray holes on basis of machine vision

A technology of precise positioning and machine vision, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low positioning accuracy, poor adaptability of tray hole positioning, and low operating efficiency, so as to improve accuracy and avoid tray deviation. Shift, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

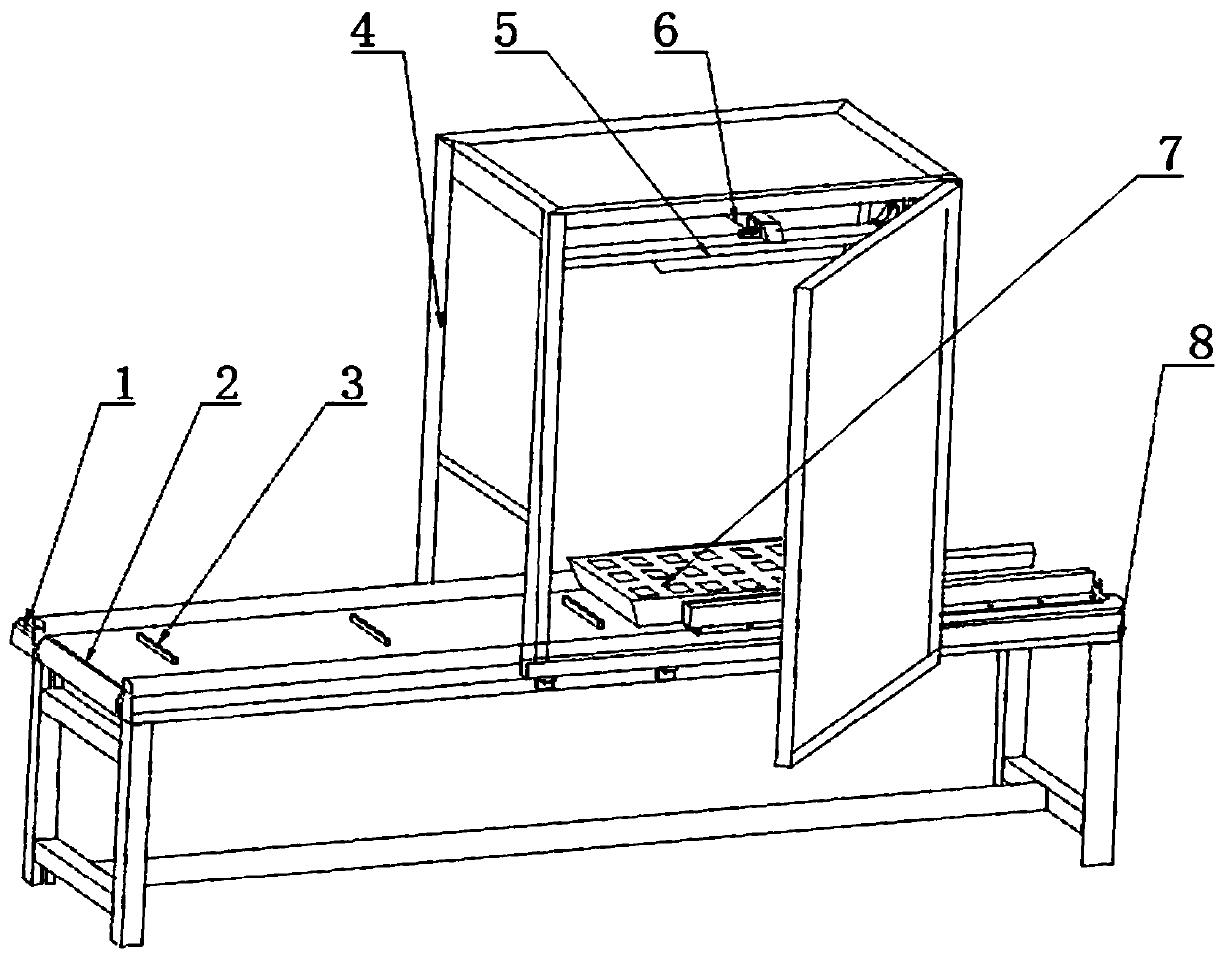

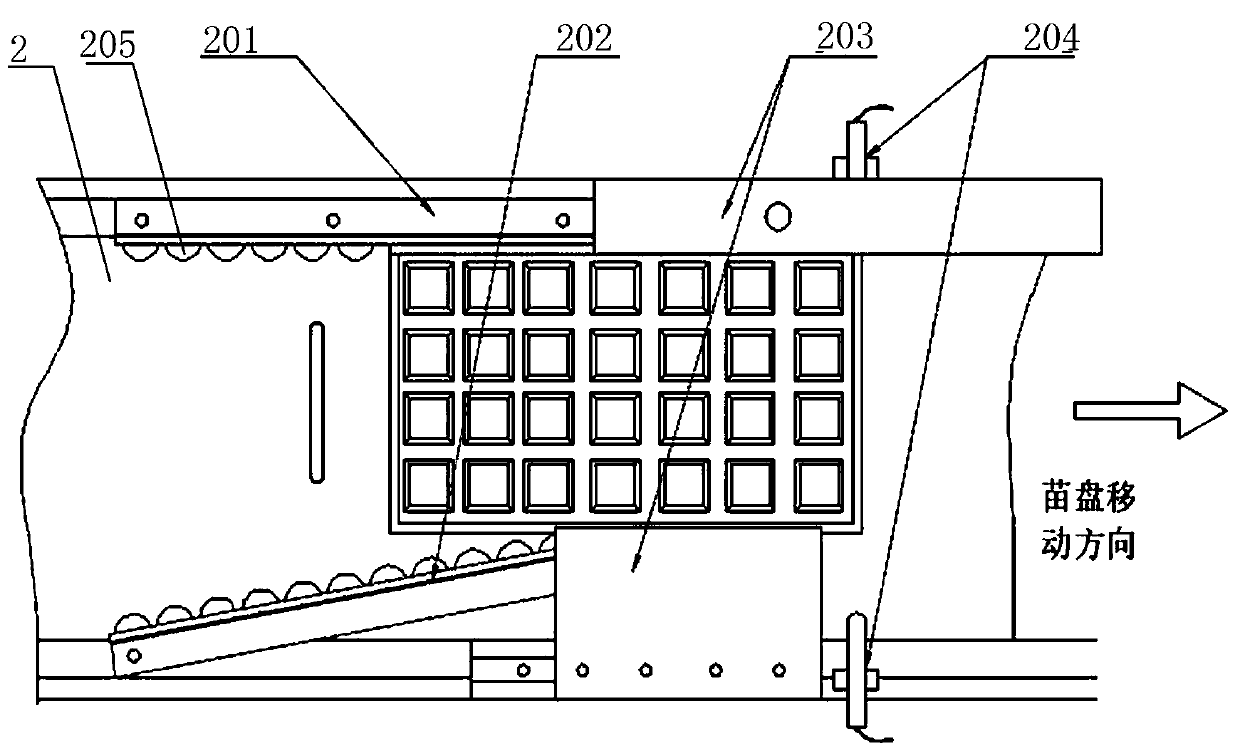

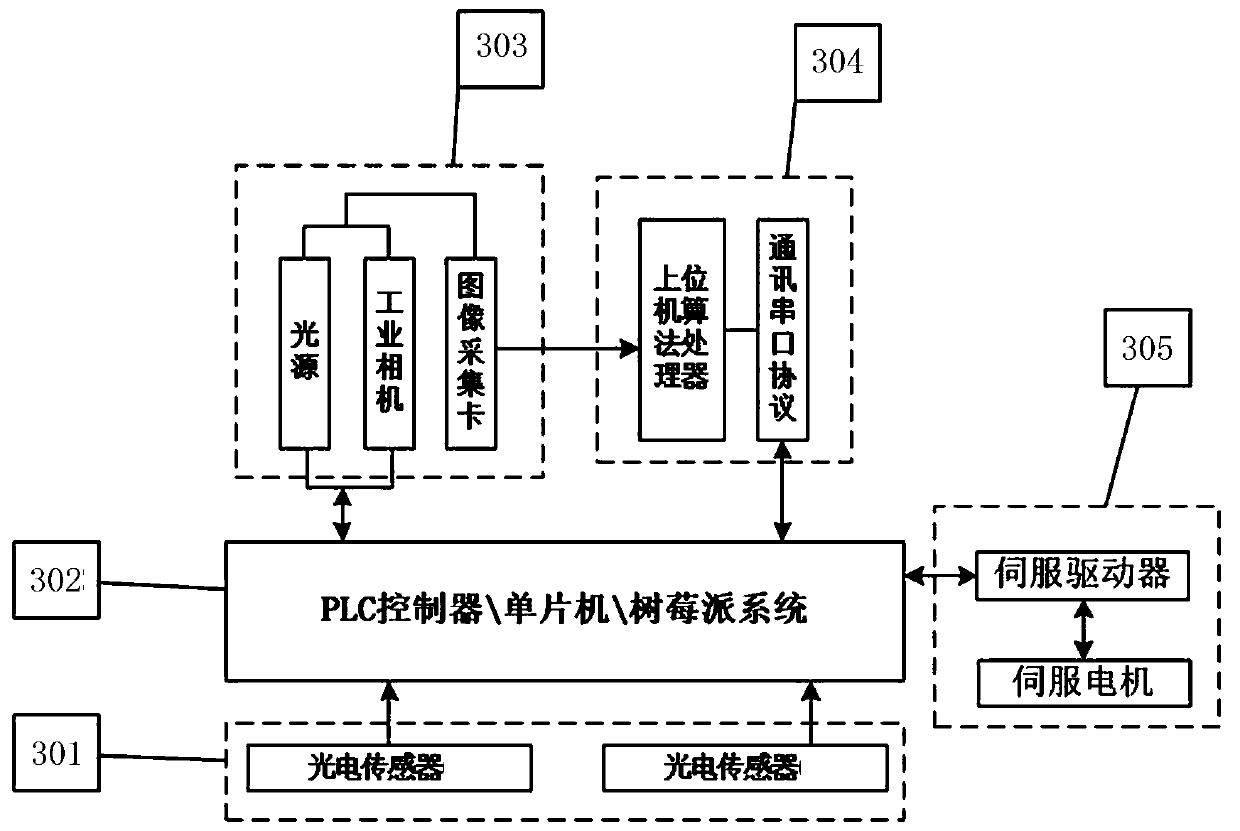

[0031] Such as figure 1 Shown, a kind of hole plate hole precise positioning device based on machine vision comprises frame 8, image acquisition device, delivery device, positioning device; Described image acquisition device, positioning device are installed on frame 8, wherein image acquisition device Installed in the middle position of the frame 8, the positioning device is installed directly below the image acquisition device; the conveying device includes a servo motor 1 and a conveyor belt 2, in order to ensure that the position of the tray 7 in the forward direction remains unchanged, the conveyor belt 2 Fixing strip 3 is housed, and described fixing strip 3 length is 200mm, and width is 20mm, and spacing is 600mm, is evenly distributed on conveyor belt 2; Black distinction; the image acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com