High-precision temperature probe on basis of cavity filled micro-structure optical fiber interferometers

A technology of microstructure optical fiber and temperature probe, applied in the field of optical fiber, to achieve the effect of good application range, expandability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The essential features and remarkable progress of the present invention will be clarified below through specific embodiments.

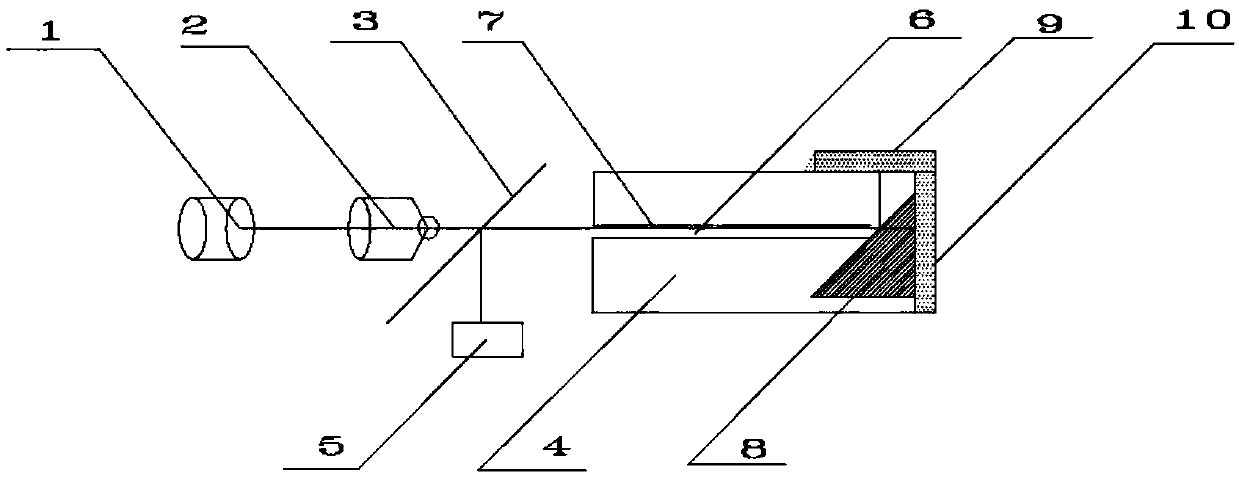

[0016] A high-precision temperature probe based on a cavity-filling microstructure optical fiber interferometer, the basic principle of which is the interference of multiple beams of light. The temperature probe designed in the present invention is mainly composed of a light source 1, a half-mirror 3, an optical fiber structure 4, and a detector 5, wherein the output wavelength range of the light source 1 is 1520-1560nm, which is a commonly used C-band near-infrared light source signal. The light emitted by the light source is first focused by an objective lens 2 with a magnification of 40 times, and then coupled into an optical fiber core 6 with a diameter of 20 microns through a 2mm thick half-mirror 3, which is made of silica and the outer optical fiber The cladding layer 7 is made of polyimide, whose refractive index is lower than that of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com