Anti-slump follow-up system for double-glass IV test components

A technology for testing components and follow-up systems, which is used in semiconductor/solid-state device testing/measurement, electrical components, conveyor objects, etc. It can solve problems such as solar cell module collapse, save space, improve stability, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

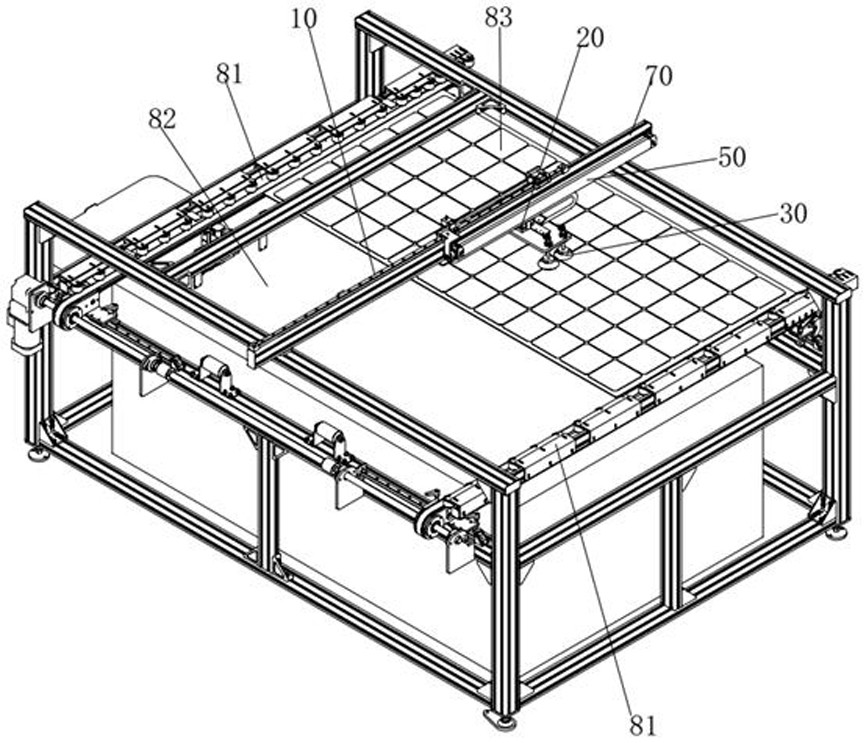

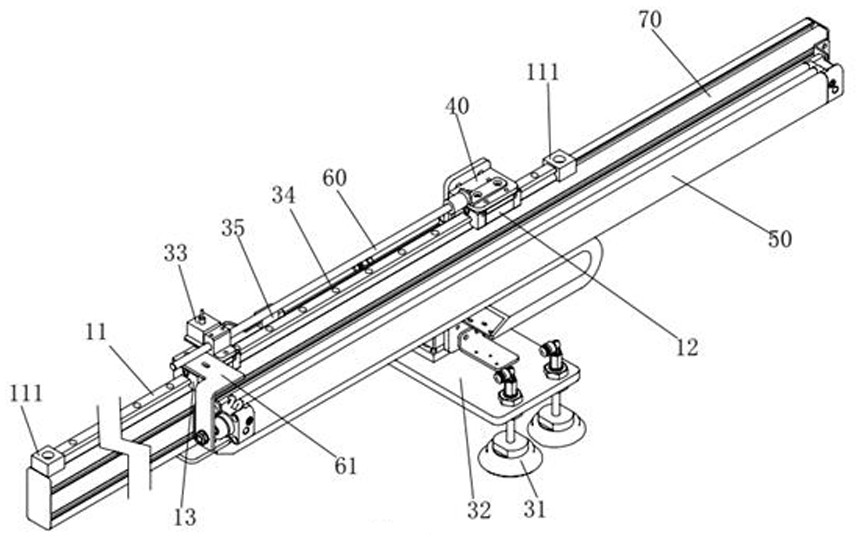

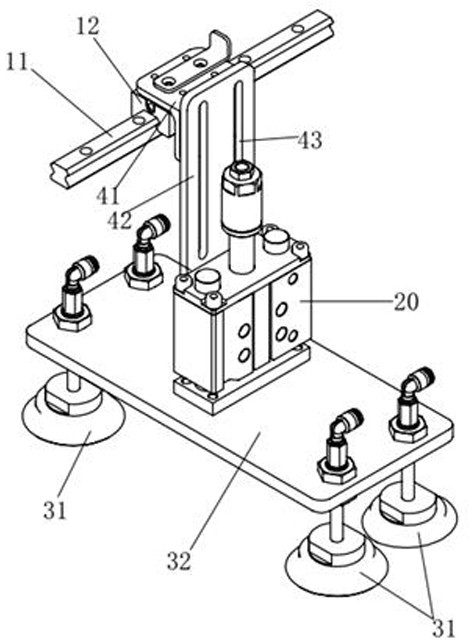

[0030] Such as figure 1 and figure 2 As shown, a double-glass IV test assembly anti-collapse follow-up system according to the embodiment of the present invention includes a bracket 70 supporting the entire anti-collapse follow-up mechanism, a grasping device 30 for grasping the collapse position of the solar cell module 83, Make the grabbing device 30 away from or close to the lifting device 20 of the solar cell assembly 83 (combined with image 3 ), the guide de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com