Ultra-wideband absorber based on combined resonant structure, and manufacturing method thereof

A resonant structure and ultra-wideband technology, which is applied in the field of ultra-wideband absorbers and their manufacturing, can solve the problems of increased device thickness, high construction time and cost, and increased design difficulty, so as to reduce thickness, time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

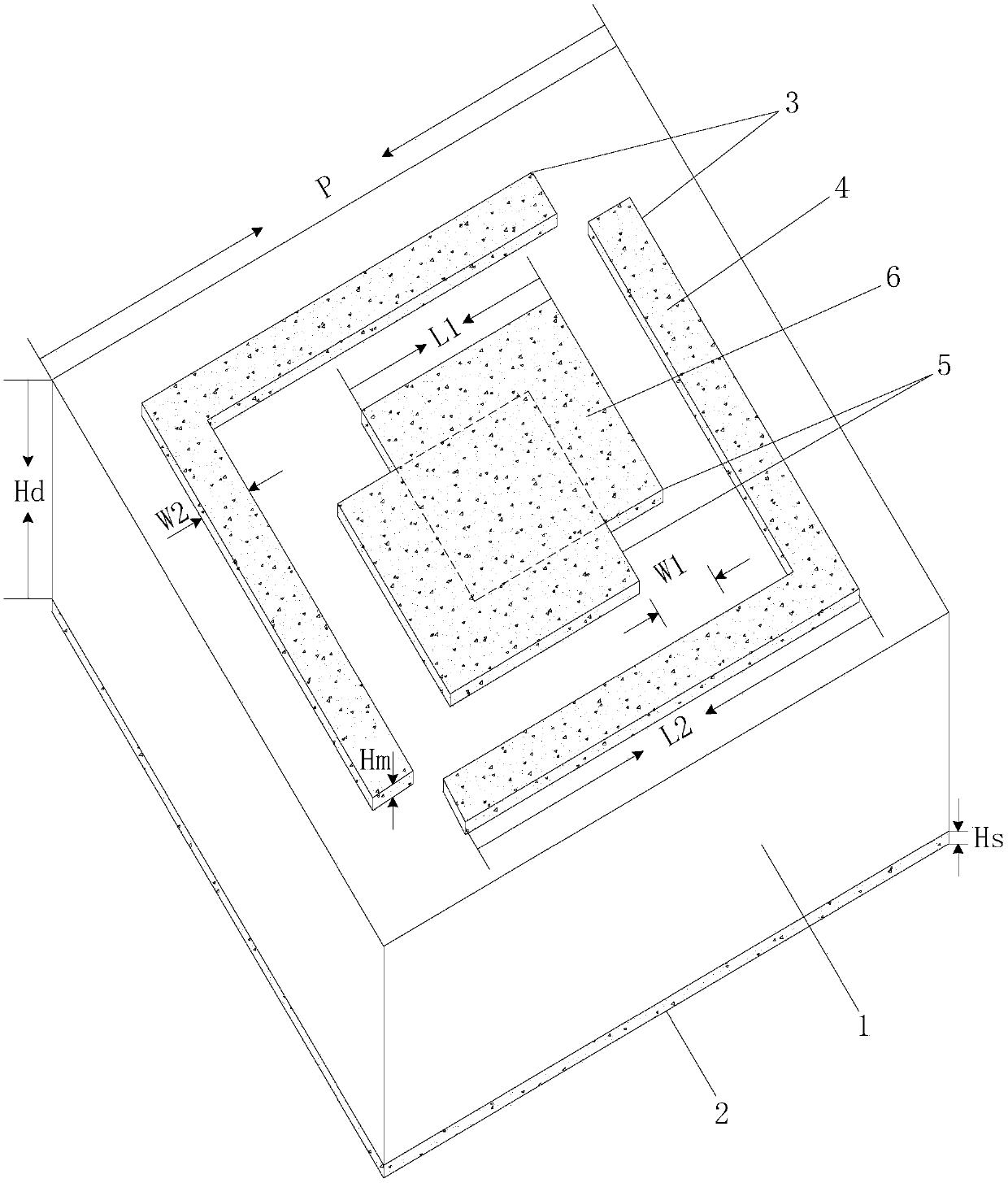

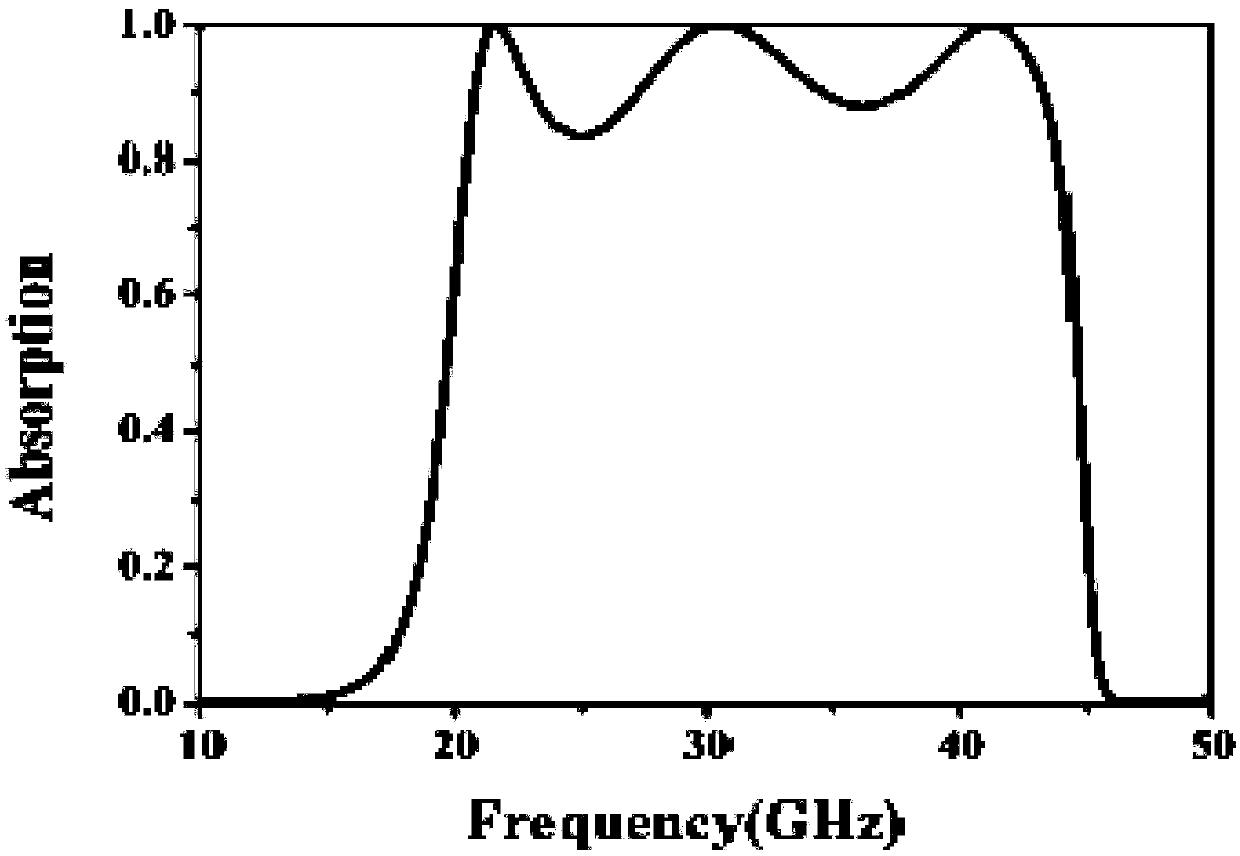

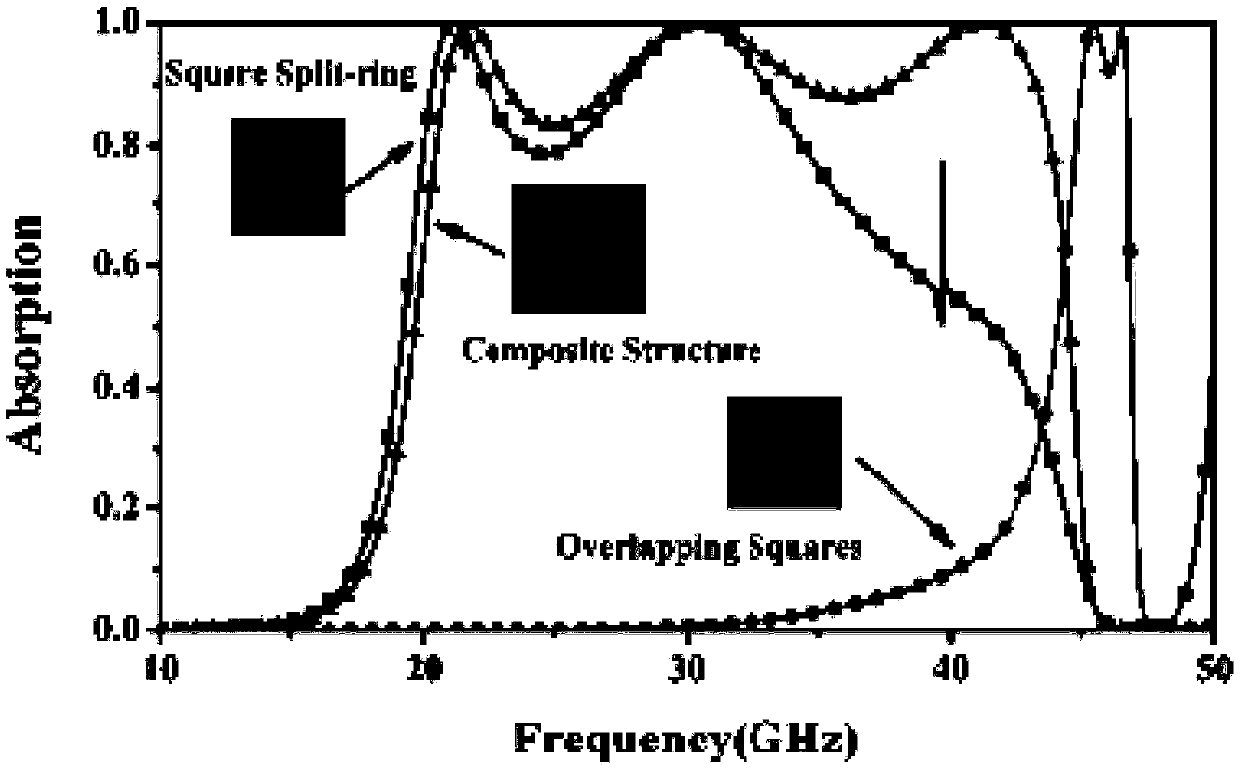

[0035] see figure 1 , this embodiment provides an ultra-broadband metamaterial absorber based on a combined resonant structure, which is used to solve many obstacles encountered in bandwidth expansion methods such as the common planar structure method and multi-layer stacking method, especially in the structural In the process of ultra-wideband metamaterial absorber, the above two methods no longer have the problem of obtaining the prerequisites for ultra-wideband absorbing. Among them, the ultra-wideband metamaterial absorber based on the combined resonant structure of this embodiment includes a dielectric layer 1, a thin film 2, a first resonant structure 3 and a second resonant structure 5, which can be applied to stealth devices (such as weapons such as stealth fighters) equipment) or solar cells.

[0036] The dielectric layer 1 has two end surfaces that are far away from each other. In this embodiment, the shape of the two end surfaces of the dielectric layer 1 is prefer...

Embodiment 2

[0049] This embodiment provides a method for manufacturing an ultra-broadband metamaterial absorber based on a combined resonant structure, which can be used to manufacture the absorber in Example 1, and includes the following steps:

[0050] (1) According to the shape of the film 2, the positioning groove is first excavated on the base material, and then the coating is started from the bottom of the positioning groove to achieve a film 2 with a preset thickness of 1; wherein, the depth of the positioning groove is not less than the dielectric layer 1 , the sum of the thicknesses of the thin film 2 and the first resonant structure 3;

[0051] (2) After the film 2 is shaped, a liquid medium material is poured into the positioning groove to form a medium layer 1 with a preset thickness of 2;

[0052] (3) After the dielectric layer 1 is shaped, a resonant material is placed on the dielectric layer 1 to form a resonant film with a preset thickness of 1, and the resonant film is et...

Embodiment 3

[0055] This embodiment provides a wave-absorbing patch, which includes a patch and a plurality of wave-absorbing components uniformly arranged on the same surface of the patch. Wherein, the patch can be made of flexible material so as to be pasted on various structures, and the wave absorber in the embodiment 1 is used as the absorber, and the film 2 is fixed on the other side of the patch. It should be noted here that the wave-absorbing sticker provided in this embodiment can be applied as a whole product. The wave-absorbing sticker provided in this embodiment can be pasted on the surface or inside of various devices to absorb electromagnetic waves, it can be pasted on various military equipment in the military field, and it can also be pasted on electronic products to prevent electromagnetic interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com