Anti-blocking chocolate dripping small fried dough twist production equipment

A technology for production equipment and chocolate, which is applied in baking, baked food processing, baking workshops, etc., and can solve the problems of low degree of integration, many handling times, and caking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

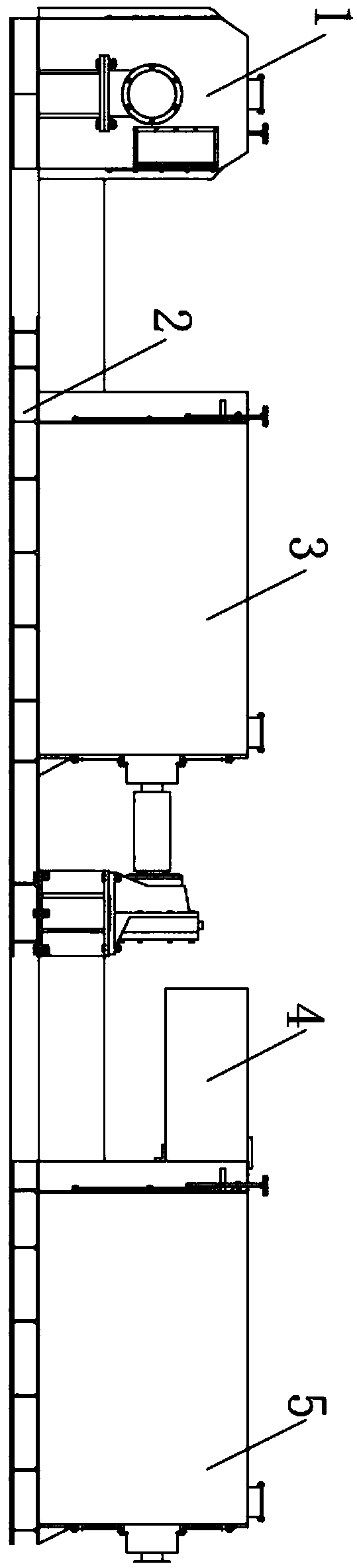

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention provides a kind of anti-caking drenched chocolate small twist production equipment, comprising a dough assembly 1, and a frying assembly 3 is provided on one side of the dough assembly 1, and a frying assembly 3 is provided on one side of the frying assembly 3. There is a coating assembly 5, the top of the coating assembly 5 near the frying assembly 3 is provided with a cooling assembly 4, and the bottom surface of the noodle assembly 1, the frying assembly 3 and the coating assembly 5 are fixedly bolted to the main mounting bracket 2, Using assembly line equipment, when in use, the flour is first kneaded in the dough kneading unit 1, and then the kneaded noodles are twisted and put into the frying unit 3, and the fried dough twists are sent to the frying unit 3. At the bottom of the cooling assembly 4, the surface of the twist is cooled, and then it is sent into the coating assembly 5, and the surfac...

Embodiment 2

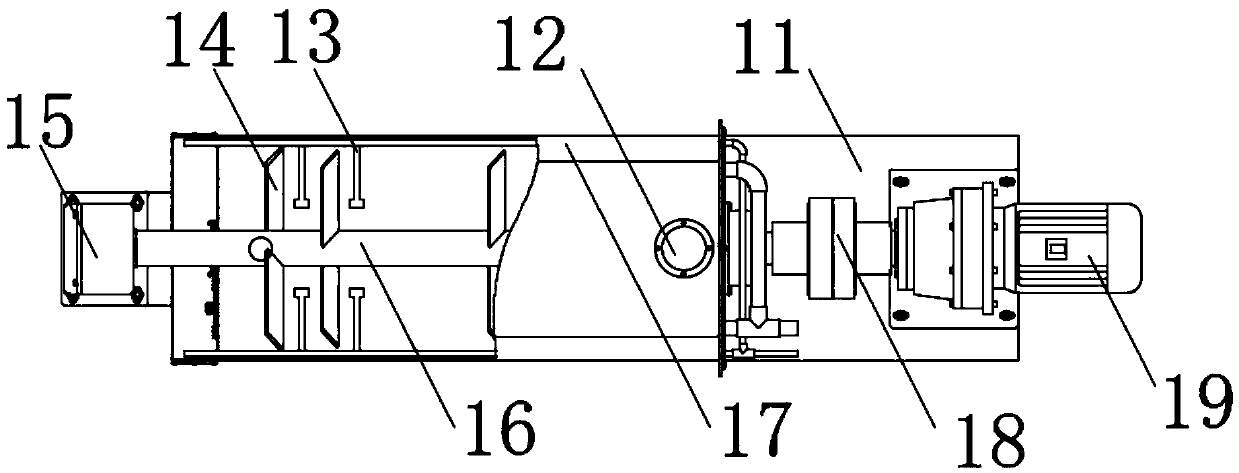

[0031] Such as figure 1 , 2 As shown, the embodiment of the present invention provides a kind of anti-caking drenched chocolate small twist production equipment, and the noodle assembly 1 includes a chassis main board 11, and the middle part of the surface of the chassis main board 11 is bolted with a noodle cavity 17, and the noodle cavity The middle part of the top of 17 is provided with a mixing surface observation window 12, and the middle part of the mixing surface cavity body 17 is fitted with a mixing surface spindle 16, and the surface of the mixing surface spindle 16 is fitted with a mixing surface rubber plate 14, and the inner chamber of the mixing surface cavity body 17 The surface is fixedly fitted with a fixed foot 13, and one end of the surface main shaft 16 is sleeved with a shaped shaft seat 15, and the other end of the surface main shaft 16 is keyed to a coupling 18, and one end of the coupling 18 is keyed to a driving motor 19 , the fixed leg 13 is embedded...

Embodiment 3

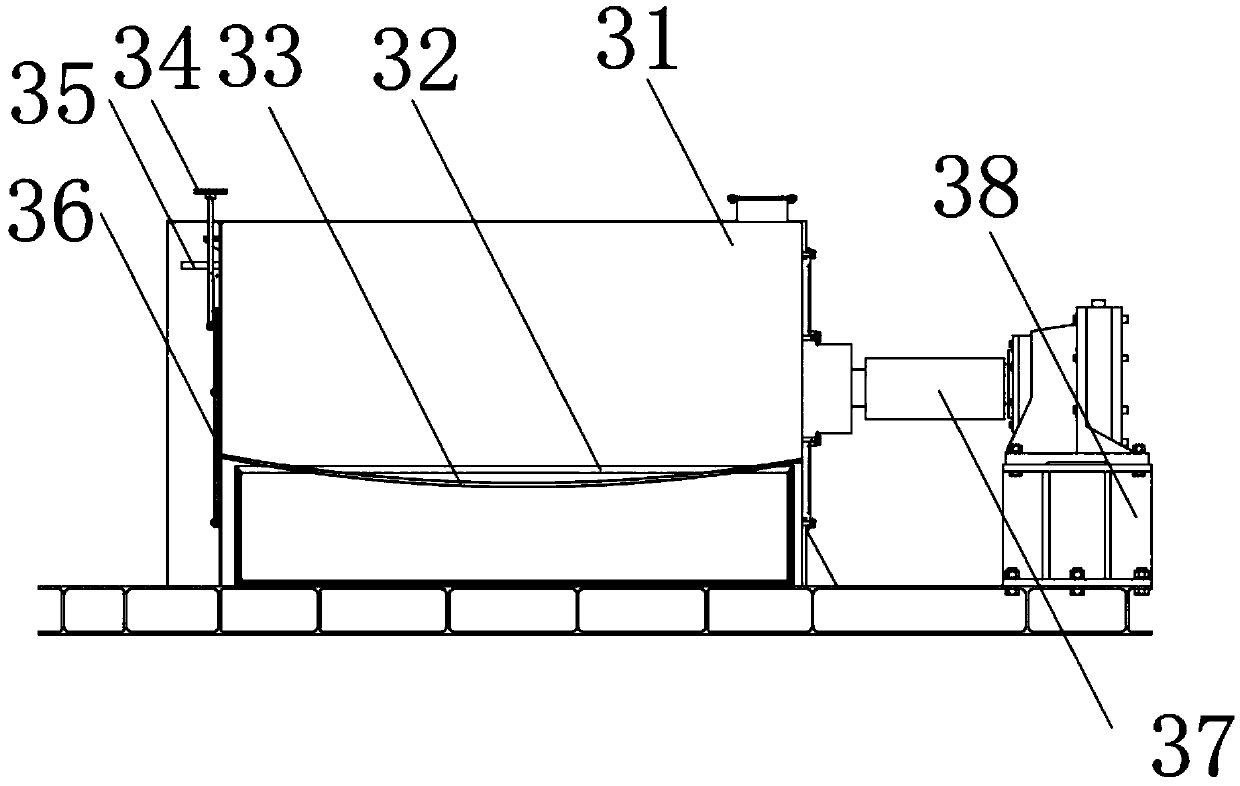

[0033] Such as figure 1 , 3 , 4, the embodiment of the present invention provides a kind of anti-caking drenched chocolate small twist production equipment, the frying assembly 3 includes a frying box 31, and the bottom of the inner cavity of the frying box 31 is fixedly provided with a main oil tank 32 , the top of the main oil tank 32 is provided with an oil immersion screen 33, the top of one side of the frying box 31 is provided with a furnace door handle 34, and the bottom of the furnace door handle 34 is provided with a heat preservation furnace door 36, and one side of the frying box 31 A furnace door bracket 35 is fixedly fitted, a reciprocating pendulum shaft 37 is provided in the middle of the other side of the frying box 31, and a positioning bracket 38 is provided at one end of the reciprocating pendulum shaft 37, and the cooling assembly 4 includes a fan housing 41 and a cooling fan 42 , the cross-section of the fan housing 41 is a honeycomb interlayer, the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com