Efficient filter cake replacement device

A high-efficiency, filter cake technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of poor permeability, equipment production capacity reduction, etc., to improve air permeability, increase equipment production capacity, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

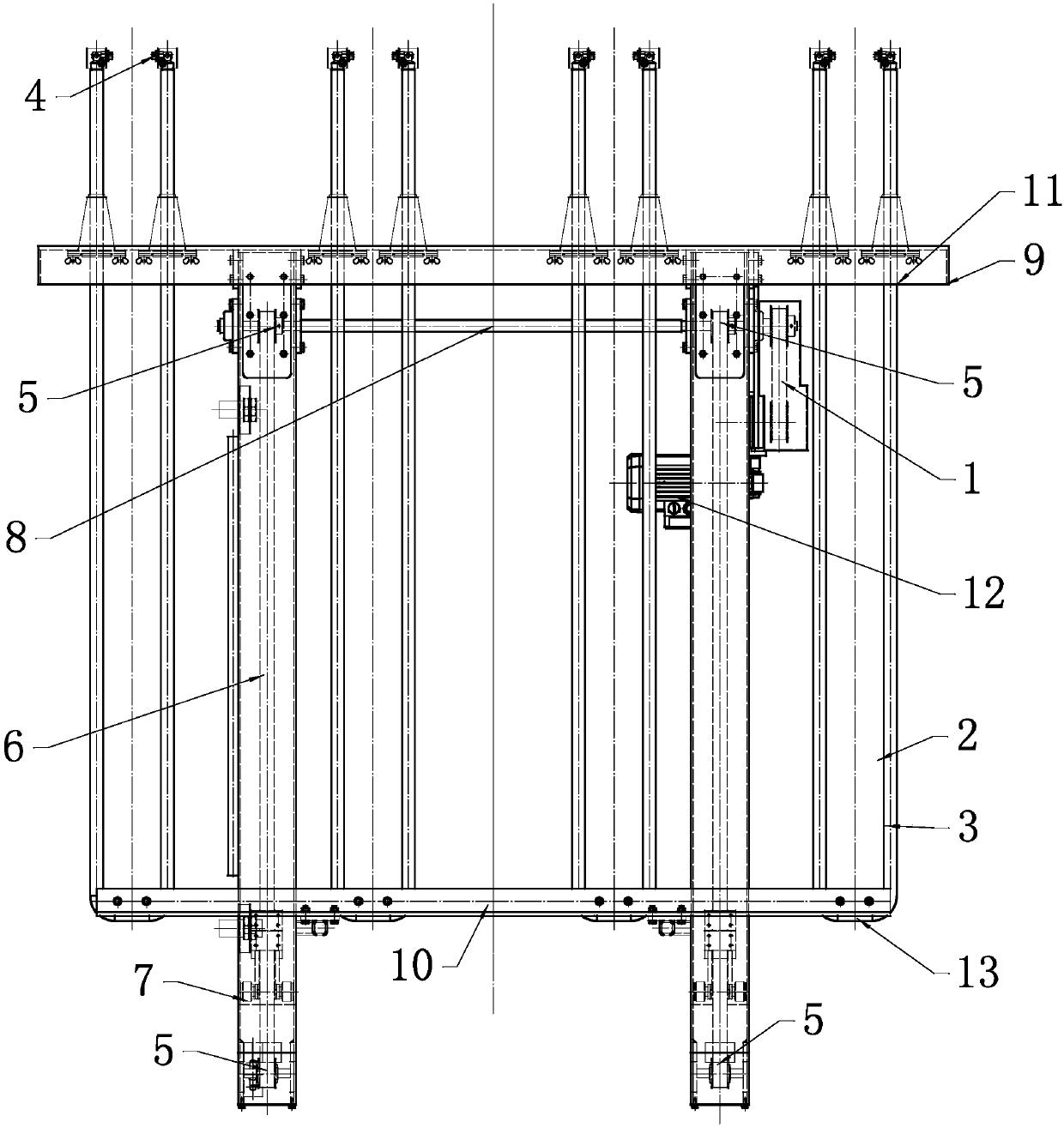

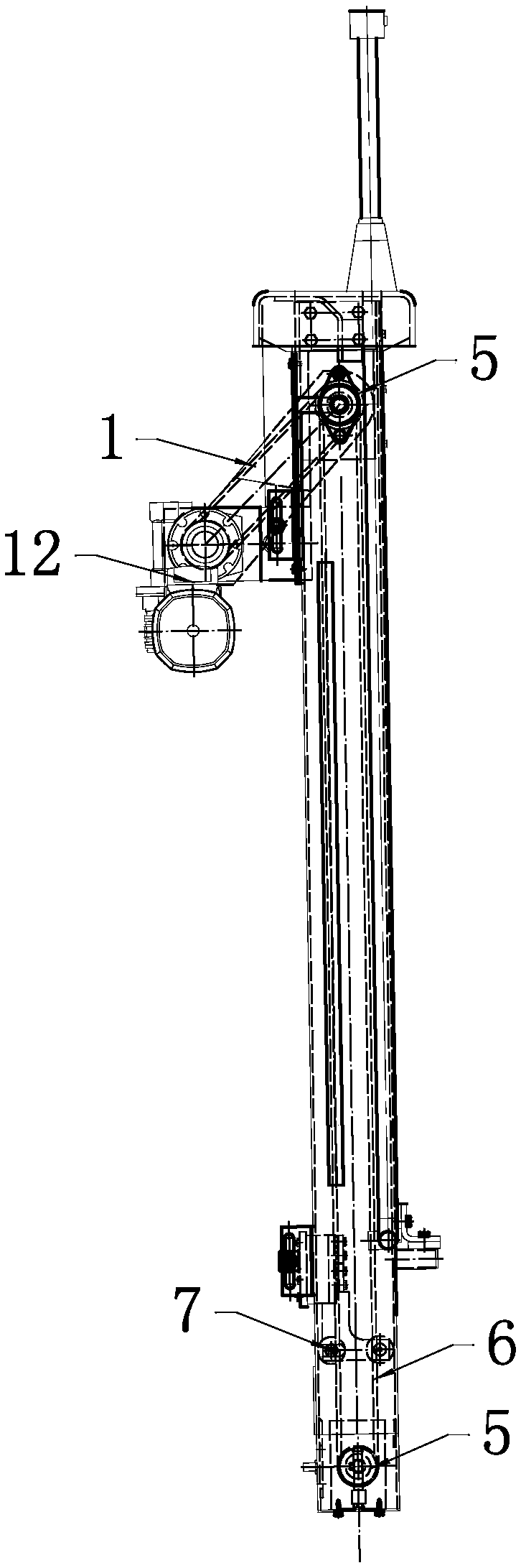

[0024] Such as figure 1 with figure 2 Commonly shown, a high-efficiency filter cake replacement device includes a fixed bracket 9, four movable intervals, high-pressure water pipes 3 arranged in parallel, and nozzles 4 installed on the high-pressure water pipes 3 . The high-pressure water pipe 3 is slidably installed on the fixed bracket 9. The fixed bracket 9 is provided with a through hole 11, and the high pressure water pipe 3 passes through the through hole 11 and slides in the through hole 11. A reinforcing part is provided on the fixed bracket 9 at the position corresponding to the through hole 11 to reduce wear between the high pressure water pipe 3 and the through hole 11 .

[0025] The high-pressure water pipe 3 has a U-shaped structure, and nozzles 4 are installed on both open ends of the high-pressure water pipe 3 , and a water inlet 13 for connecting high-pressure water is provided on the high-pressure water pipe 3 . The water receiving port 13 is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com