Coal-fired boiler SCR denitration process and ammonia/air mixer thereof

A technology for coal-fired boilers and mixers, applied in fluid mixers, mixers, gas treatment, etc., can solve problems such as ammonia/air mixer clogging, and achieve the effects of solving clogging, low manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

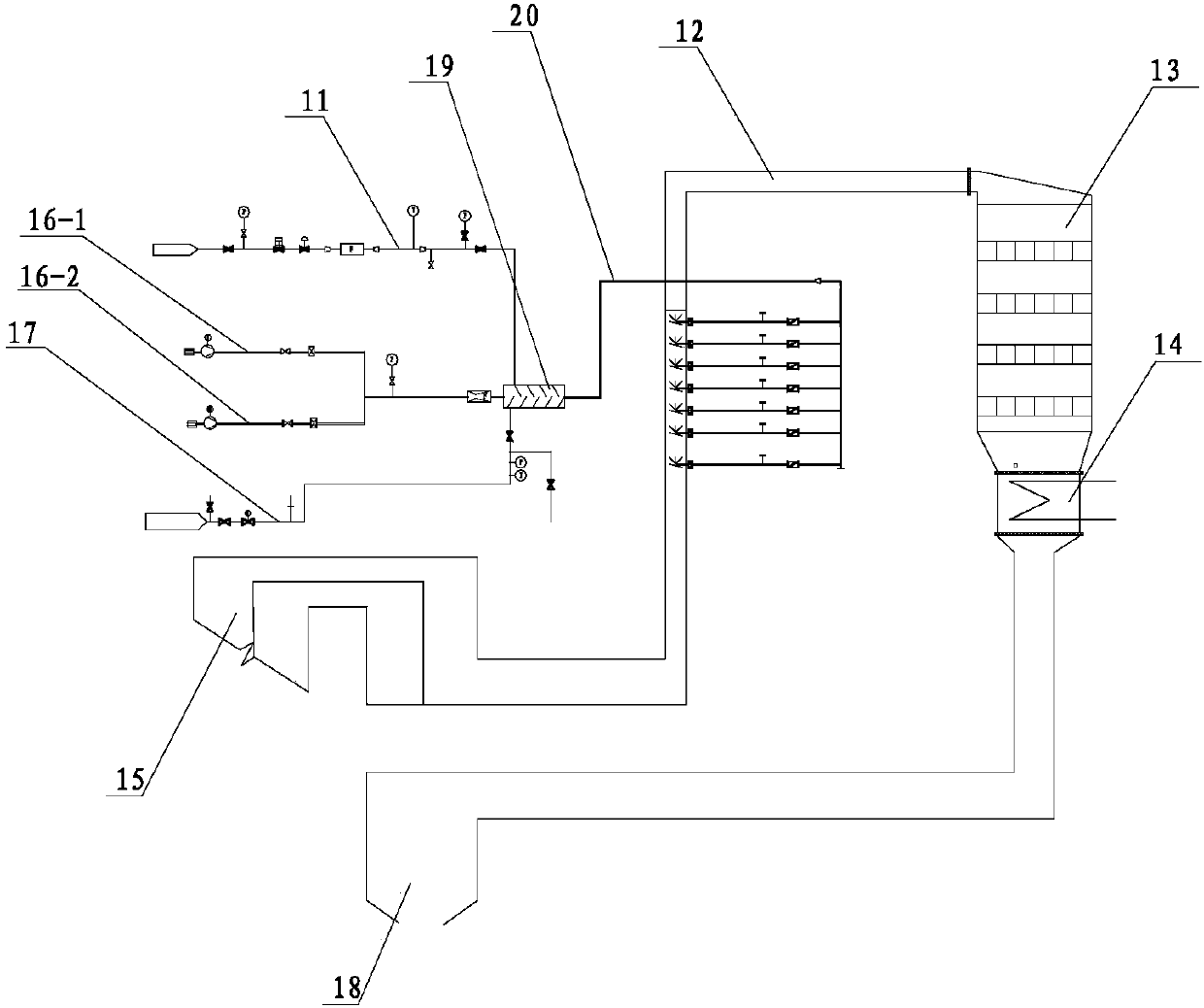

[0032] A coal-fired boiler SCR denitrification process described in this embodiment, the flue gas generated by the boiler is discharged through the denitrification device after spraying ammonia, so as to realize the SCR denitrification of the boiler;

[0033] Among them, the flow of ammonia gas entering the ammonia injection grid is controlled, and the diluted ammonia gas is evenly distributed in the flue and the NO in the flue gas X Fully mixed, when the mixed flue gas reaches the catalyst area of the denitrification device, a chemical reaction occurs to remove the NO in the flue gas X Decomposed into water and nitrogen.

[0034] A catalyst layer and a catalyst reserve layer are arranged in the denitration reactor.

[0035] The ammonia gas for ammonia injection is ammonia gas diluted with air, and the volume ratio of ammonia gas is ≤5%.

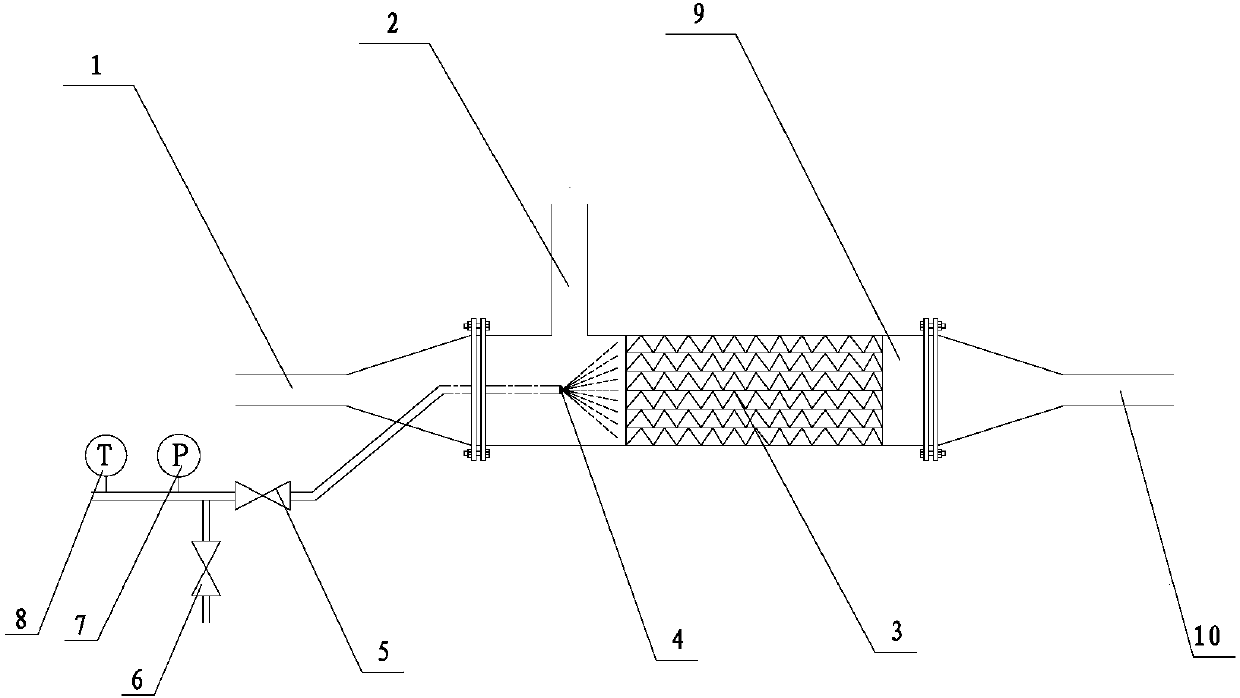

[0036] The ammonia / air mixer for the SCR denitrification process of the coal-fired boiler comprises an ammonia / air mixer main body 9, t...

Embodiment 2

[0053] The denitrification process and device of the present invention are the same as in Example 1, except that the ammonia source of the ammonia / air mixer: the ammonia gas entering the ammonia / air mixer enters through the denitrification ammonia gas pipe, and the inlet pressure is 0.6MPa.

Embodiment 3

[0055] The denitrification process and device of the present invention are the same as those in Example 1, the difference being that the ammonia gas source of the ammonia / air mixer: the ammonia gas entering the ammonia / air mixer enters through the denitrification ammonia gas pipe, and the inlet pressure is 0.3 MPa.

[0056] After 4,000 hours of normal operation of a certain coal-fired boiler, it was found that the dilution air volume of the SCR flue gas denitrification device decreased from 3,500Nm3 / h to 2,600Nm 3 / h, at this time, it is judged that the ammonia / air mixer is blocked by ammonium salt crystallization, dust, water vapor impurities and other mixtures on the surface of the equalizing corrugated plate after long-term use, which reduces the dilution air volume. The dilution air volume is close to the limit alarm value, which will cause the denitrification device to shut down.

[0057] At this point the ammonia / air mixer is steam purged. After arriving at the site, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com