Multi-line cutting method, multi-line cutting device and application thereof, semiconductor material and power device

A multi-wire cutting and cutting-line technology, which is applied in the fields of semiconductor materials and power devices, multi-wire cutting methods and multi-wire cutting devices, can solve the problems of difficult processing of semiconductor substrates, achieve small warpage and increase energy , The effect of enhancing the cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

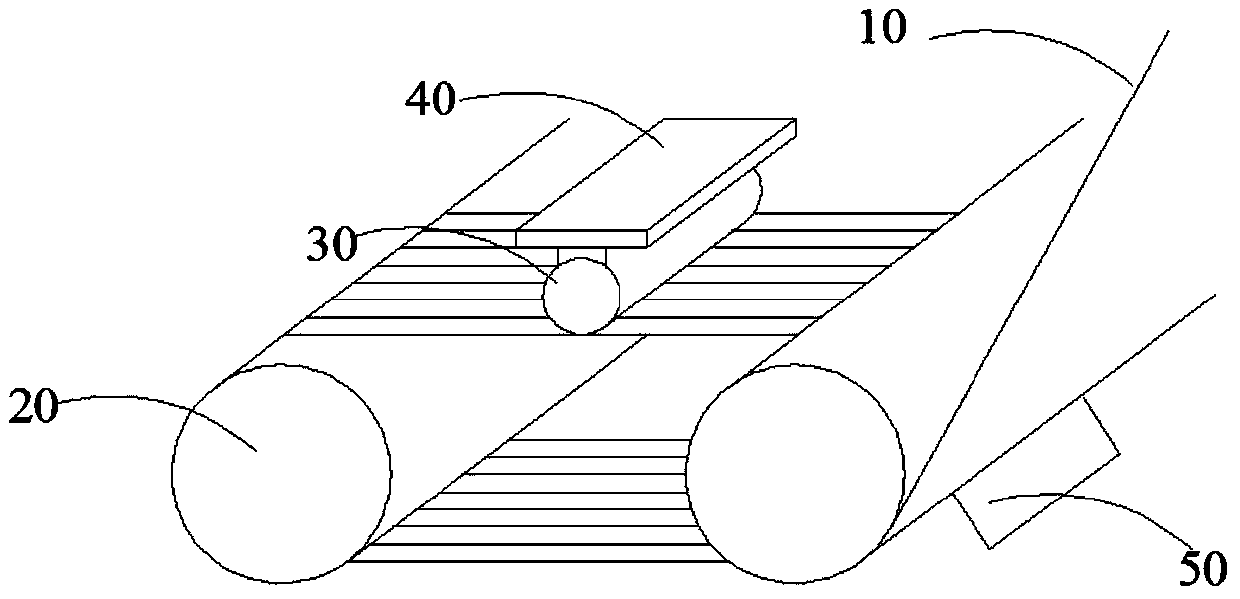

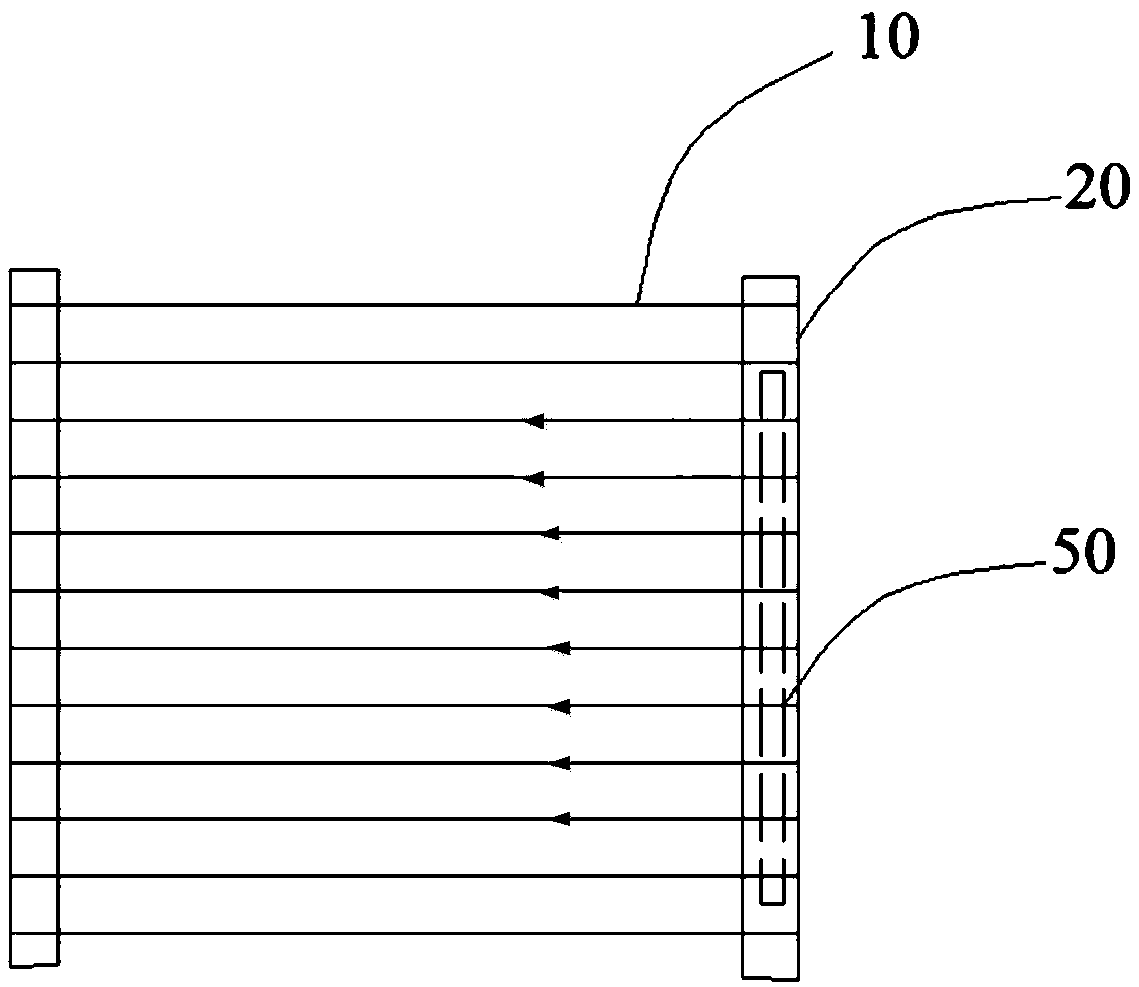

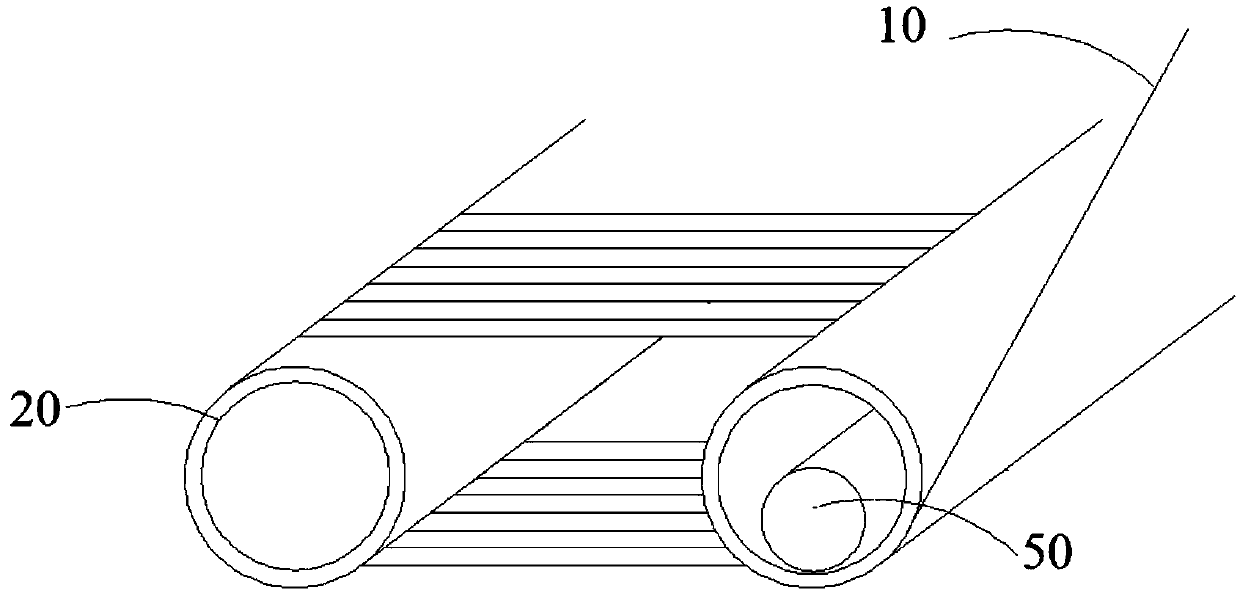

[0066] Multi-wire cutting methods include:

[0067] The spool is in contact with the vibrating head of the ultrasonic generator, and the spool vibrates under the excitation of ultrasonic waves with a frequency of 20kHz. Under the transmission of the spool, the cutting line vibrates and the object to be cut is cut. The diameter of the cutting line is 0.2mm , The moving speed of the cutting line is 500 m / min.

Embodiment 2

[0069] The multi-wire cutting method is the same as in Example 1, except that the frequency of the ultrasonic wave is 300 kHz.

Embodiment 3

[0071] The multi-wire cutting method is the same as in Example 1, except that the frequency of the ultrasonic wave is 150kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com