A kind of die-cutting processing method of liquid glue printing to protective film

A processing method and protective film technology, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of die-cutting and printing coordination, unguaranteed dimensional tolerance, waste of a large amount of materials, etc., and achieve saving The effect of debugging materials, improving yield and production efficiency, and improving matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

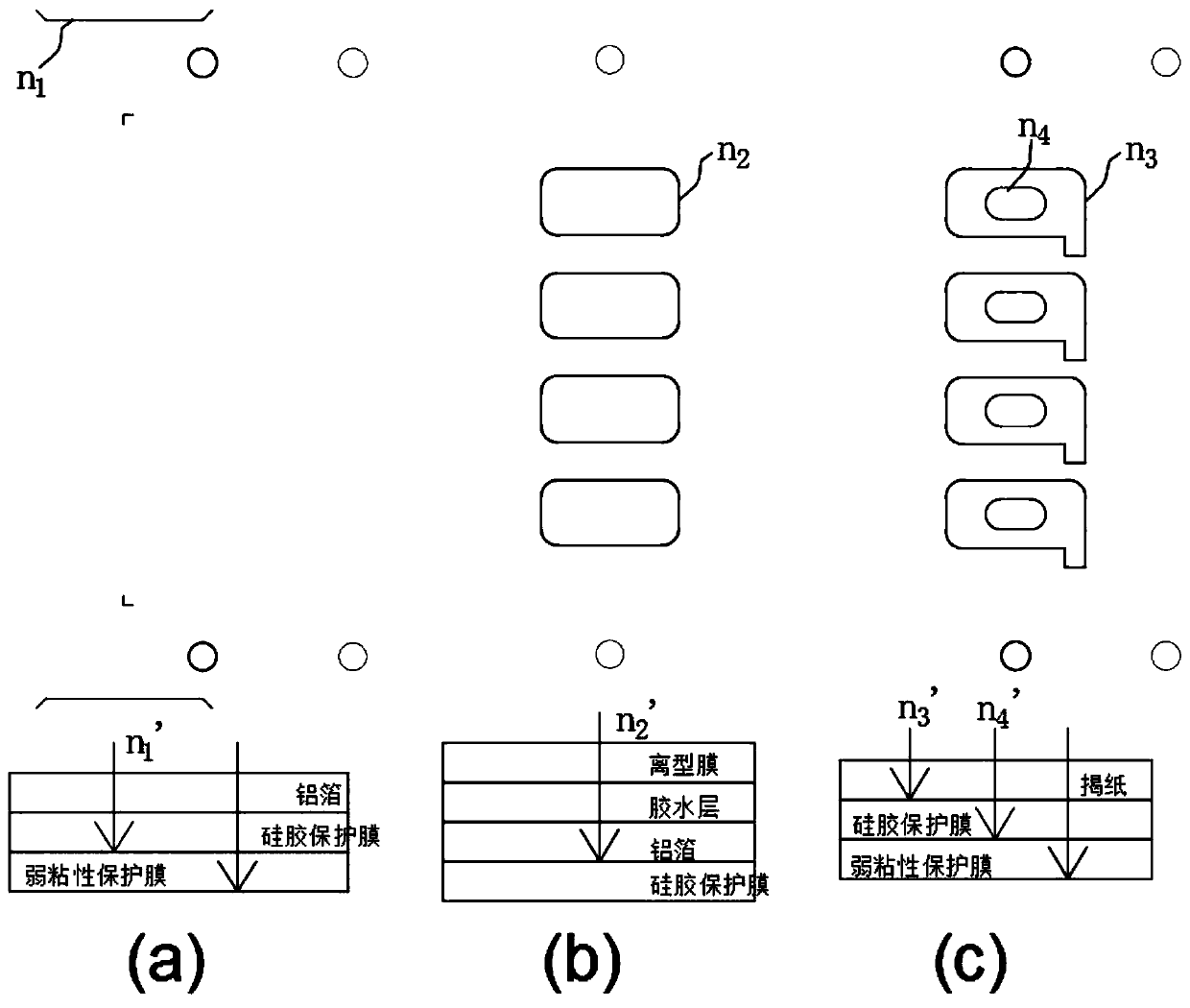

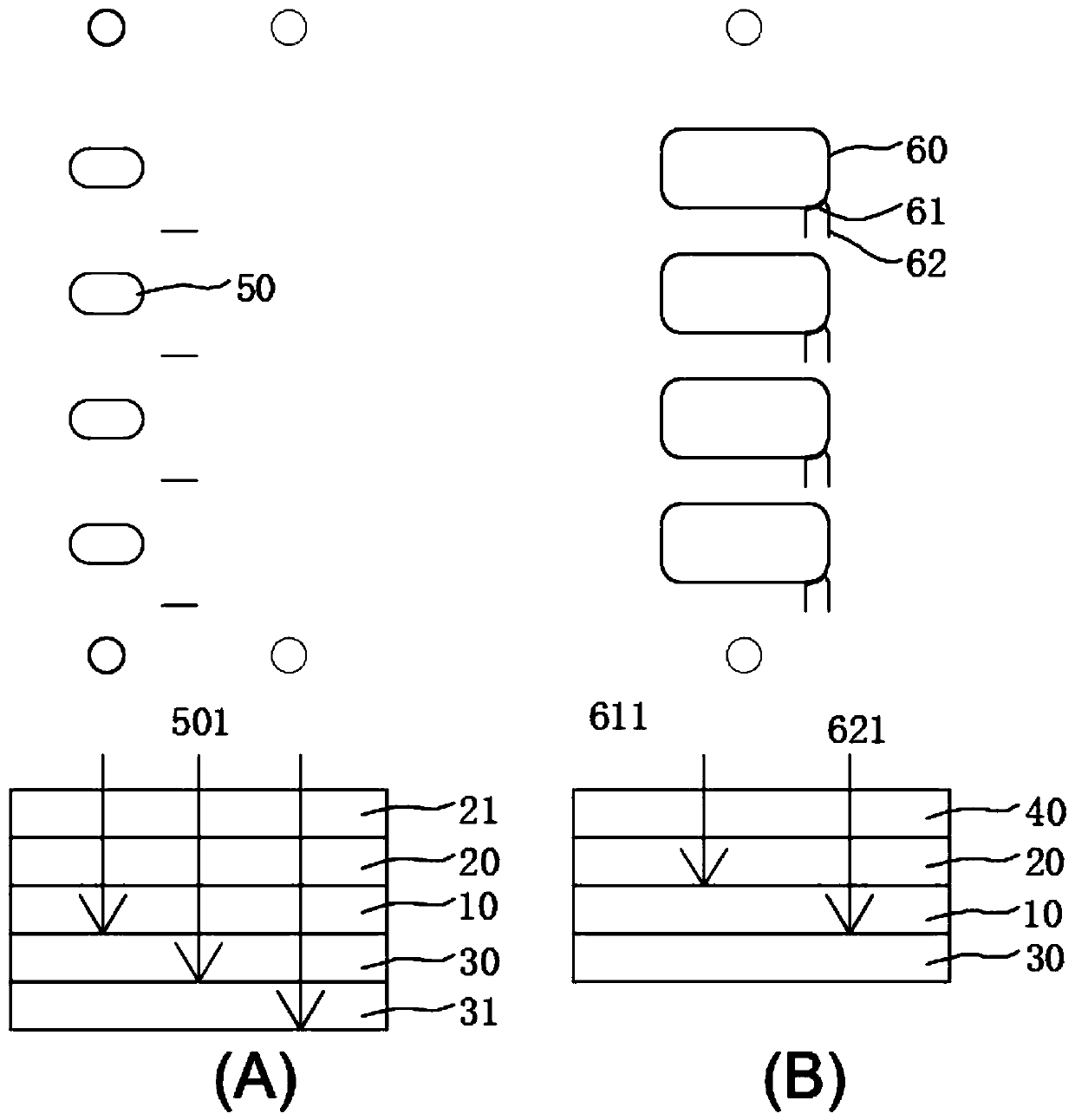

[0029] refer to image 3 As shown, the present invention discloses a die-cutting processing method for liquid glue printing onto a protective film, the following steps:

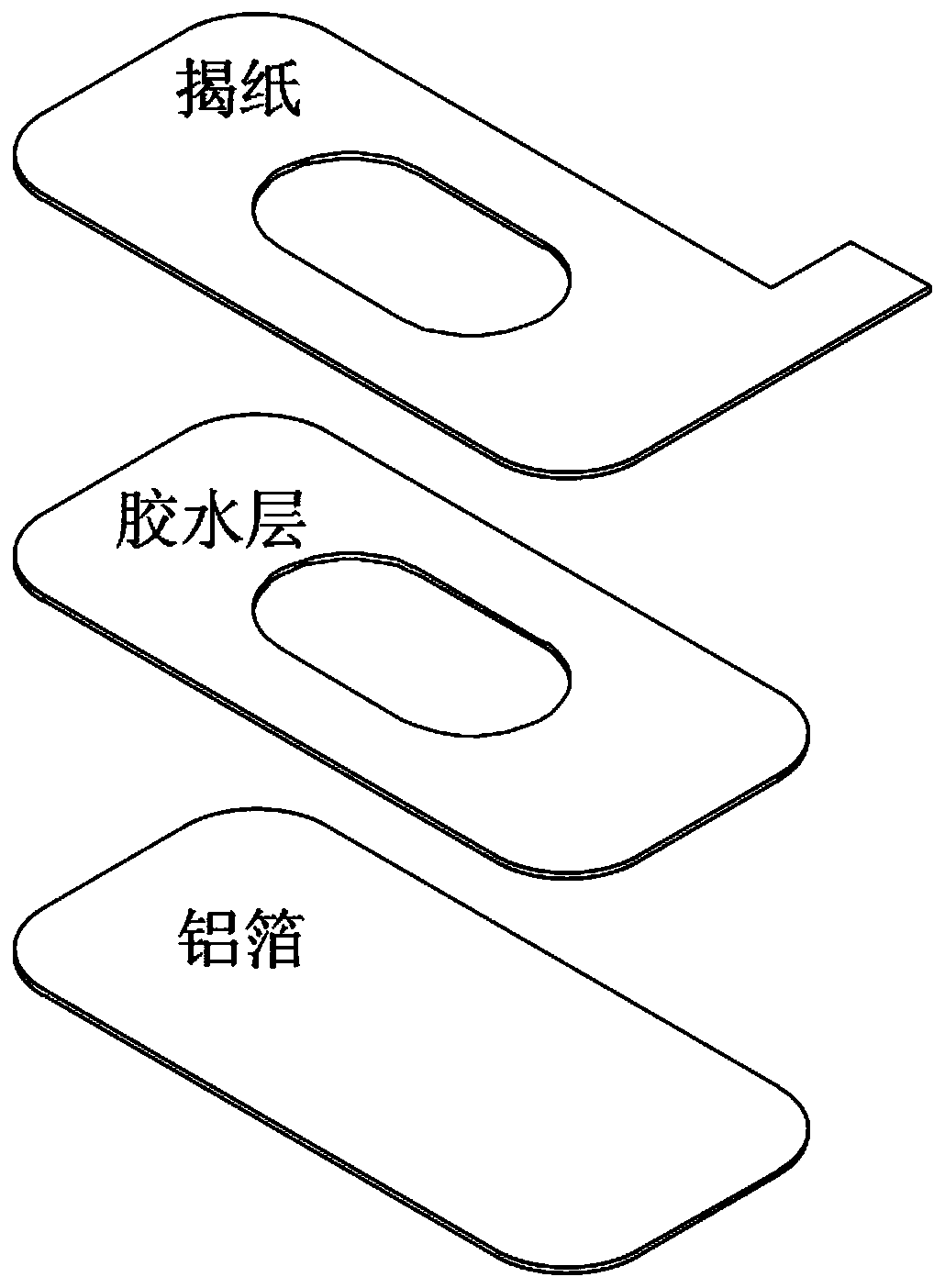

[0030] Step 1: Print liquid glue on the silicone protective film 10 , and then the liquid glue solidifies to form the glue layer 20 . Wherein, the curing may be performed by drying. In this embodiment, the liquid glue can be selected from 3M SP7533 model.

[0031] Step 2: Cover the glue layer 20 with a release film 21 to obtain a composite film layer. Wherein, the composite film layer includes a silicone protective film 10 , a glue layer 20 and a release film 21 sequentially arranged from bottom to top.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com