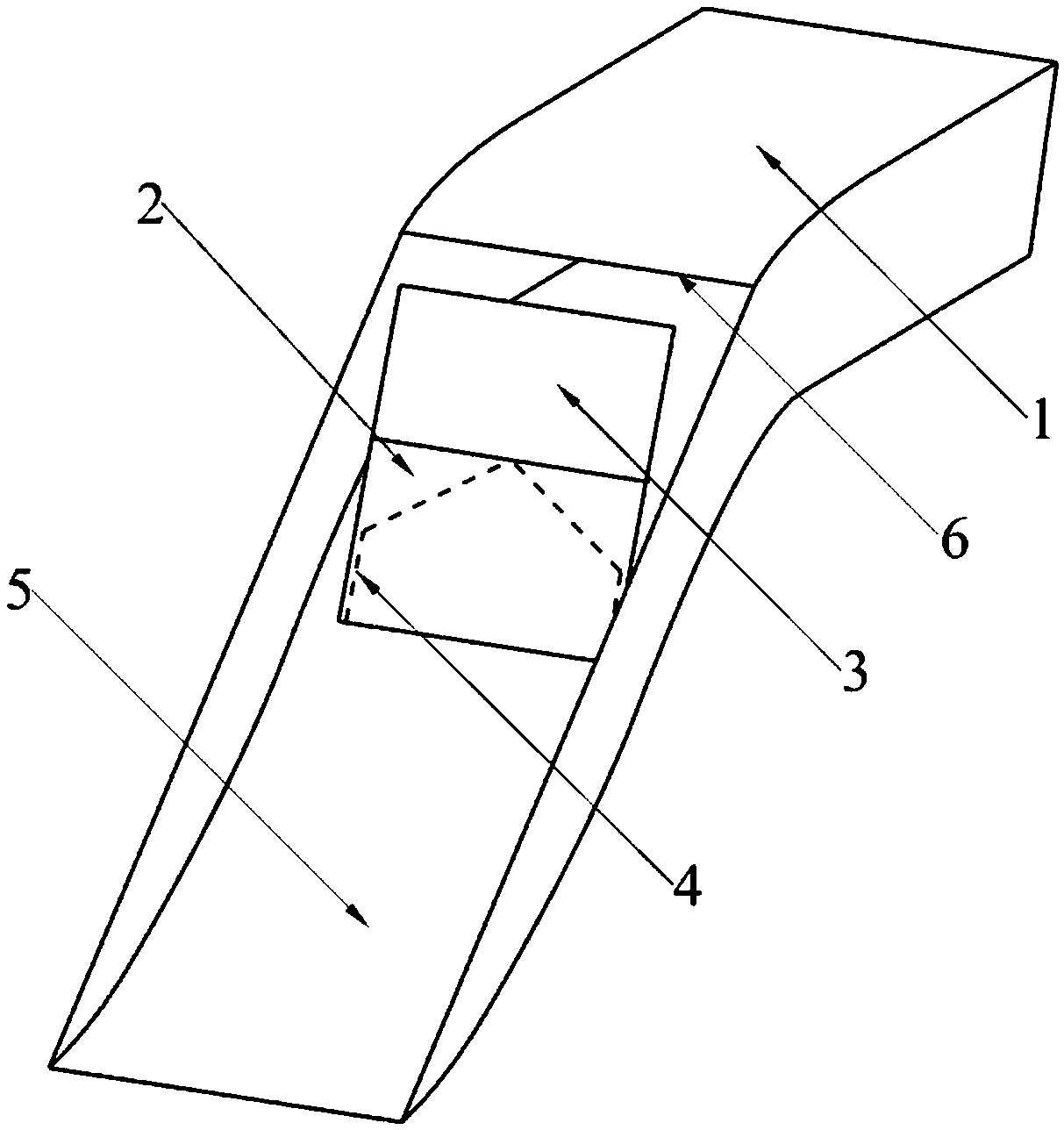

Super-high-hypersonic-speed two-dimensional inlet channel starting assisted vortex control adjustable valve device

A hypersonic and valve device technology, applied in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems of boundary layer removal, acceleration to high speed, acceleration, etc., to achieve control and facilitate restarting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

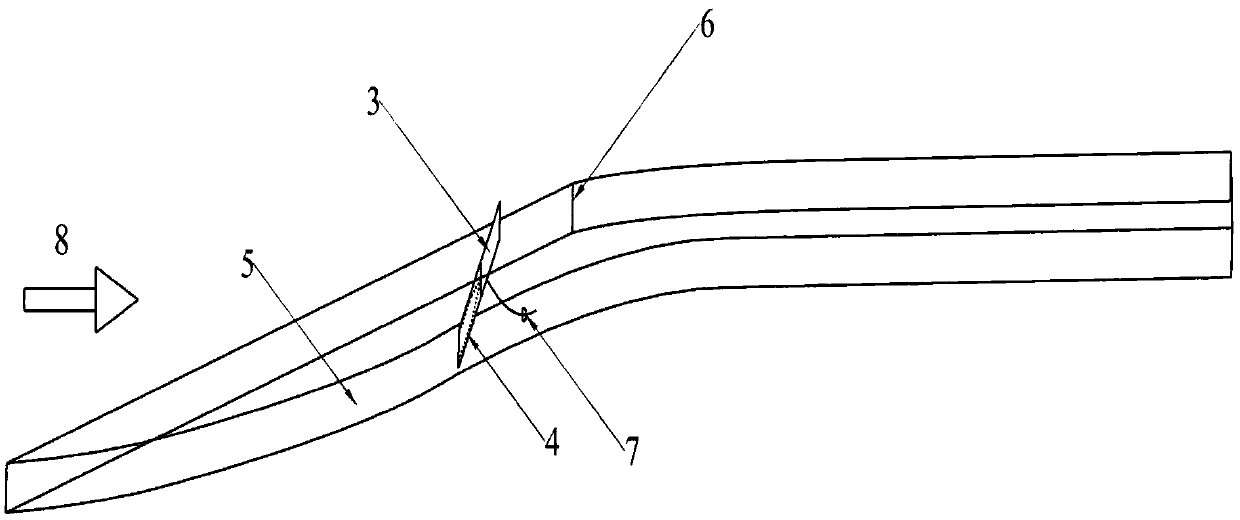

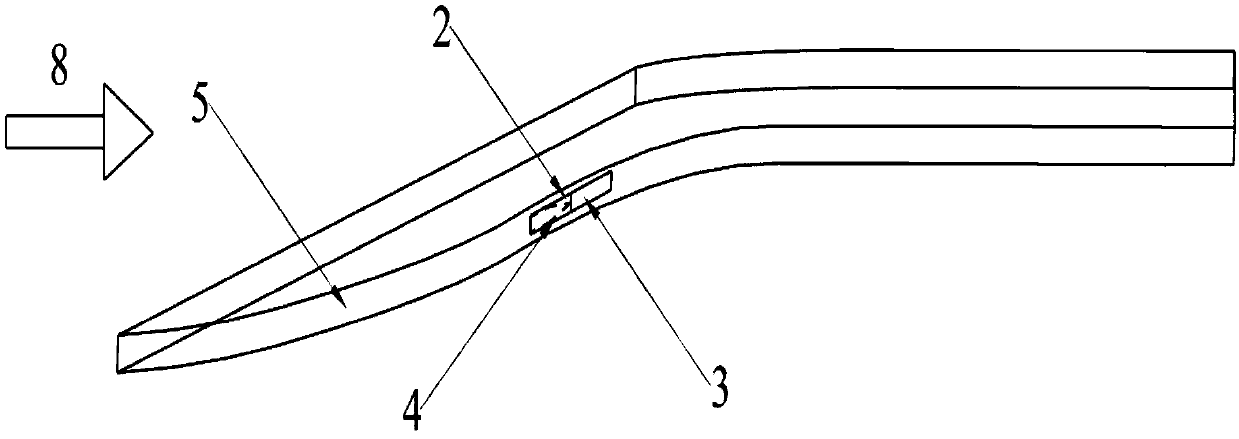

[0039] The present invention can be used for auxiliary start when the relay point air intake is just opened and restart control after non-start, and the specific implementation method is as follows:

[0040] 1. For the auxiliary start when the relay point air intake is just opened, the following steps are included:

[0041] 1.1) Before the ramjet works, the main rotary valve rotates to the maximum position θ maxAt this point, the inlet of the air intake is sealed. At this time, the angle between the main rotary valve and the bottom wall of the air intake is the largest, and a shock wave is formed on the surface, the secondary rotary valve is closed, and the airflow does not enter the air intake;

[0042] 1.2) When reaching the relay point, the secondary valve first opens to a certain degree, and then starts to gradually rotate the main valve (the angle between the main rotary valve and the bottom wall of the intake duct decreases), and the intake duct gradually opens. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com