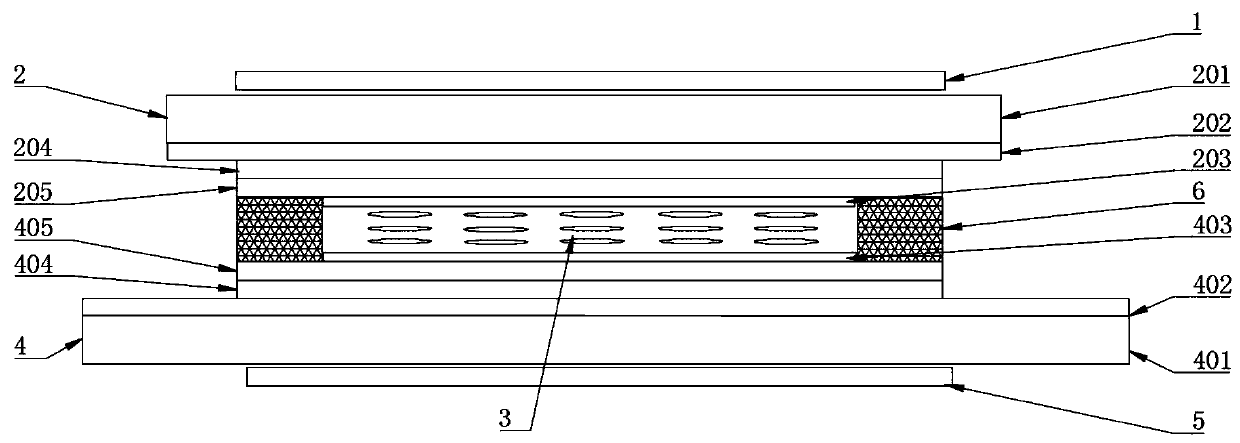

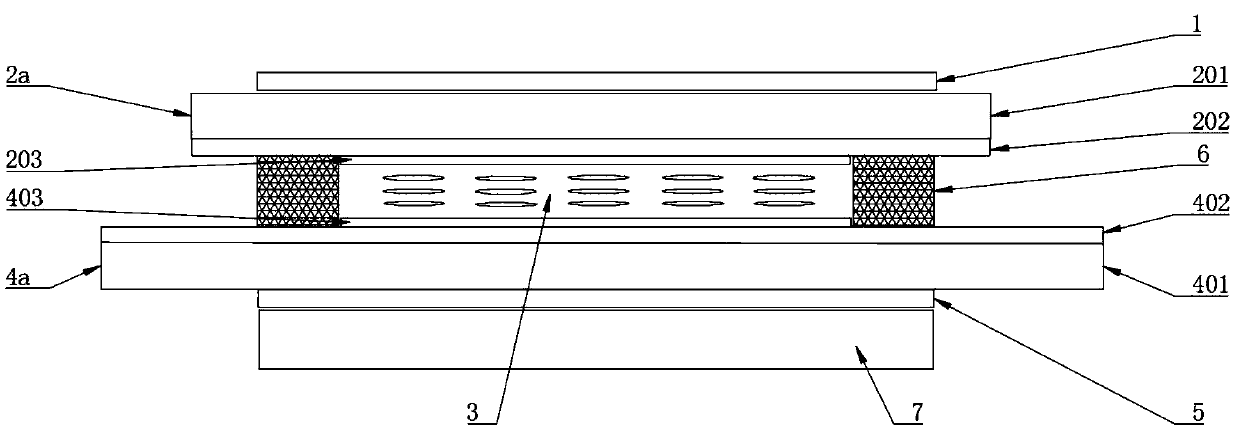

Luminous ITO (Indium Tin Oxide) glass substrate and preparation method thereof

A glass substrate and light-emitting layer technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of power consumption and limited life of the backlight source, increase the production cost of liquid crystal displays, and cannot fully meet the display requirements, and achieve a simple structure. , Wide range of use, the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the upper luminous ITO glass substrate 2 and the lower luminous ITO glass substrate 4 comprises the following steps:

[0031] (1) After pre-soaking, pre-PR cleaning, photoresist coating, exposure, development, film hardening, etching, stripping, and pre-PI cleaning procedures, conventional ITO glass is sent to a tunnel furnace to dry the glass surface moisture. Prepare for printing of the luminescent layer;

[0032] (2) Preparation of light-emitting layer materials: use NMP, add nano-particle alkaline earth aluminate long afterglow material, nano-particle alkaline earth aluminate long afterglow material is mainly based on aluminate, mixed with rare earth elements to spread Eu 2+ As an activator, and add Dy 3+ or Nd 3+ As an auxiliary activator, the addition amount is 1%-20% of NMP, and a dispersant is added. The dispersant is sodium tripolyphosphate, and the addition amount is 0.1%-6% of the total amount of materials in the light-emitting lay...

Embodiment 2

[0039] The preparation method of the upper luminous ITO glass substrate 2 and the lower luminous ITO glass substrate 4 comprises the following steps:

[0040] (1) After pre-soaking, pre-PR cleaning, photoresist coating, exposure, development, film hardening, etching, stripping, and pre-PI cleaning procedures, conventional ITO glass is sent to a tunnel furnace to dry the glass surface moisture. Prepare for printing of the luminescent layer;

[0041] (2) Preparation of light-emitting layer materials: use PI polymers, the PI polymers are one or more of soluble PI polymers, add nano-particle alkaline earth aluminate long afterglow materials, nano-particle alkaline earth aluminate long afterglow materials The material is mainly based on aluminate, doped with rare earth elements to pave Eu 2+ As an activator, and add Dy 3+ or Nd 3+ As an auxiliary activator, the addition amount is 1%-20% of the PI polymer, adding a dispersant, the dispersant is sodium hexametaphosphate and sodium...

Embodiment 3

[0048] The preparation method of the upper luminous ITO glass substrate 2 and the lower luminous ITO glass substrate 4 comprises the following steps:

[0049] (1) After pre-soaking, pre-PR cleaning, photoresist coating, exposure, development, film hardening, etching, stripping, and pre-PI cleaning procedures, conventional ITO glass is sent to a tunnel furnace to dry the glass surface moisture. Prepare for printing of the luminescent layer;

[0050] (2) Prepare the light-emitting layer material: mix PI polymer and NMP, the PI polymer is one or more of soluble PI polymers, add nano-particle alkaline earth aluminate long afterglow material, nano-particle alkaline earth aluminate Salt long afterglow materials are mainly based on aluminate, doped with rare earth elements to cover Eu 2+ As an activator, and add Dy 3+ or Nd 3+ As an auxiliary activator, the addition amount is 1%-20% of the mixture of PI polymer and NMP, and the dispersant is added. The dispersant is triethylhexyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com