Nutritional meal replacement powder and preparation method thereof

A technology for meal replacement powder and nutrition, applied in food ingredients as taste improver, food processing, food science, etc., can solve the problem of less consideration, and achieve the effect of reducing oil content, saving costs, and enhancing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

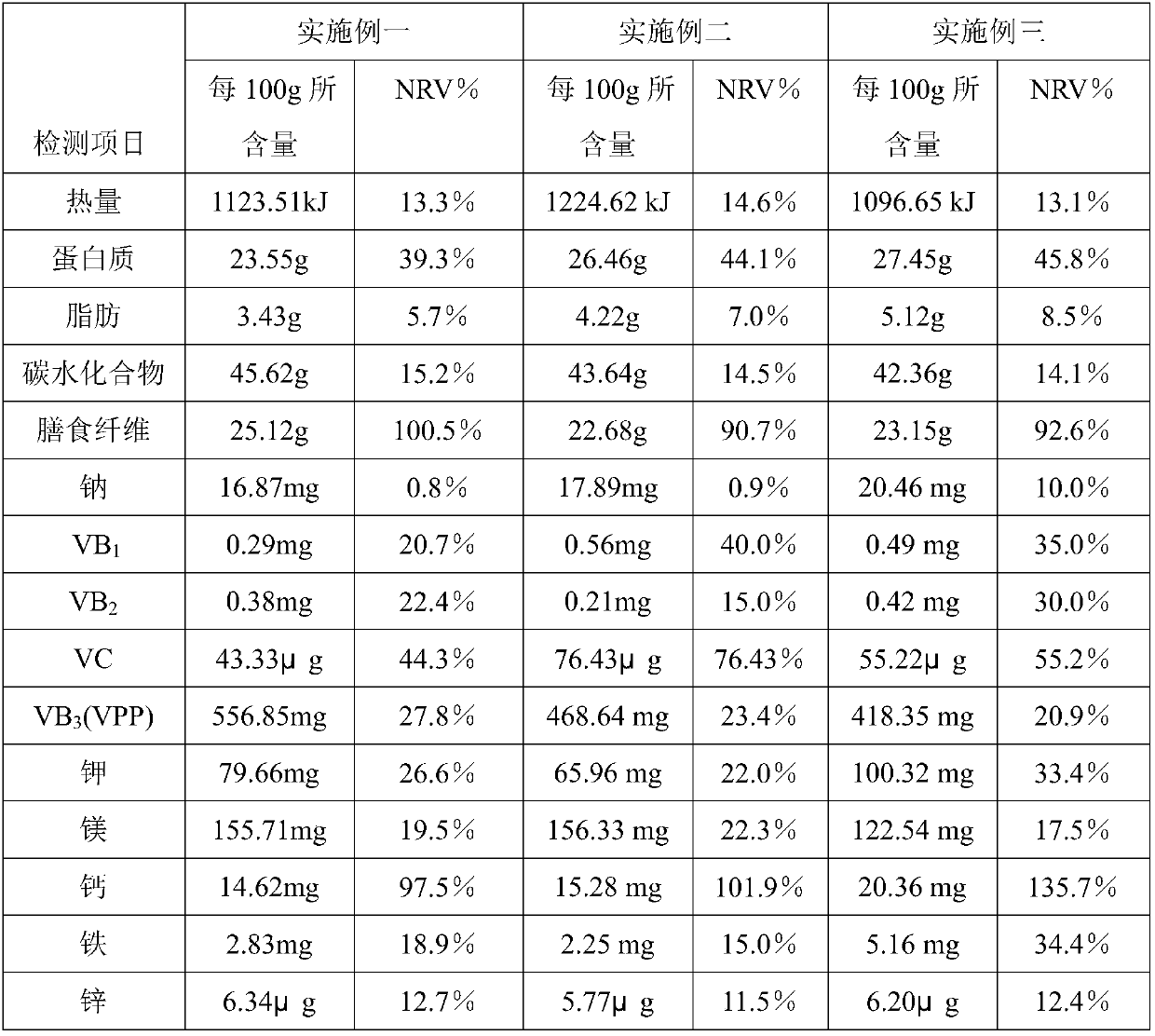

Examples

Embodiment 1

[0022] The nutritional meal replacement powder of Example 1 is prepared by the following method, including steps:

[0023] 1) Shell and crush walnuts, hazelnuts, pine nuts, pumpkin seeds, almonds, pecans and macadamia nuts, crush sesame seeds and cashew nuts, take crushed walnut kernels 20kg, hazelnut kernels 10kg, pine nuts 5kg, sesame seeds 5kg, pumpkin 10kg of nuts, 10kg of cashew nuts, 10kg of almonds, 10kg of pecan nuts and 10kg of macadamia nuts are mixed evenly, and the evenly mixed nut kernel powder is placed in a supercritical carbon dioxide extraction device to extract oil, and the residue after oil extraction is collected. The residue is pulverized in an ultrafine pulverizer to obtain protein powder with a particle size of 200 mesh;

[0024] 2) Peel kiwi, cantaloupe, banana, passion fruit, add cherry tomatoes and grapes, take 9kg of cherry tomatoes, 9kg of grapes, 9kg of kiwi pulp, 6kg of cantaloupe pulp, 6kg of banana pulp and 3kg of passion fruit pulp and mix them...

Embodiment 2

[0029] The nutritional meal replacement powder of Example 2 is prepared by the following method, including steps:

[0030] 1) Shell and crush walnuts, hazelnuts, pine nuts, pumpkin seeds, almonds, pecans and macadamia nuts, crush sesame and cashew nuts, take crushed walnut kernels 30kg, hazelnut kernels 20kg, pine nuts 10kg, sesame seeds 2kg, pumpkin 20kg of nuts, 20kg of cashew nuts, 20kg of almonds, 20kg of pecan nuts and 20kg of macadamia nuts are mixed evenly, and the evenly mixed nut kernel powder is placed in a supercritical carbon dioxide extraction device to extract oil, and the residue after oil extraction is collected. The residue is pulverized in an ultrafine pulverizer to obtain protein powder with a particle size of 400 mesh;

[0031] 2) Peel kiwi, cantaloupe, banana, and passion fruit, add cherry tomatoes and grapes, take 10kg of cherry tomatoes, 10kg of grapes, 10kg of kiwi pulp, 5kg of cantaloupe pulp, 5kg of banana pulp and 5kg of passion fruit pulp and mix th...

Embodiment 3

[0036] The nutritional meal replacement powder of Example 3 is prepared by the following method, including steps:

[0037] 1) Shell and crush walnuts, hazelnuts, pine nuts, pumpkin seeds, almonds, pecans and macadamia nuts, crush sesame seeds and cashew nuts, take crushed walnut kernels 25kg, hazelnut kernels 14kg, pine nuts 7kg, sesame seeds 3kg, pumpkin 12kg of nuts, 11kg of cashew nuts, 17kg of almonds, 16kg of pecan nuts and 14kg of macadamia nuts are mixed evenly, and the evenly mixed nut kernel powder is placed in a supercritical carbon dioxide extraction device to extract oil, and the residue after oil extraction is collected. The residue is pulverized in an ultrafine pulverizer to obtain protein powder with a particle size of 300 mesh;

[0038] 2) Peel kiwi, cantaloupe, banana, and passion fruit, add cherry tomatoes and grapes, take 11kg of cherry tomatoes, 12kg of grapes, 13kg of kiwi pulp, 6kg of cantaloupe pulp, 8kg of banana pulp and 4kg of passion fruit pulp, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com