Lead storage battery paste mixing device

A technology of lead-acid battery and paste machine, which is applied in the direction of lead-acid battery electrodes, mixers, transportation and packaging, etc. It can solve the problems of working environment pollution, plate batch quality accidents, enterprise losses, etc., to reduce pollution and improve equipment The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

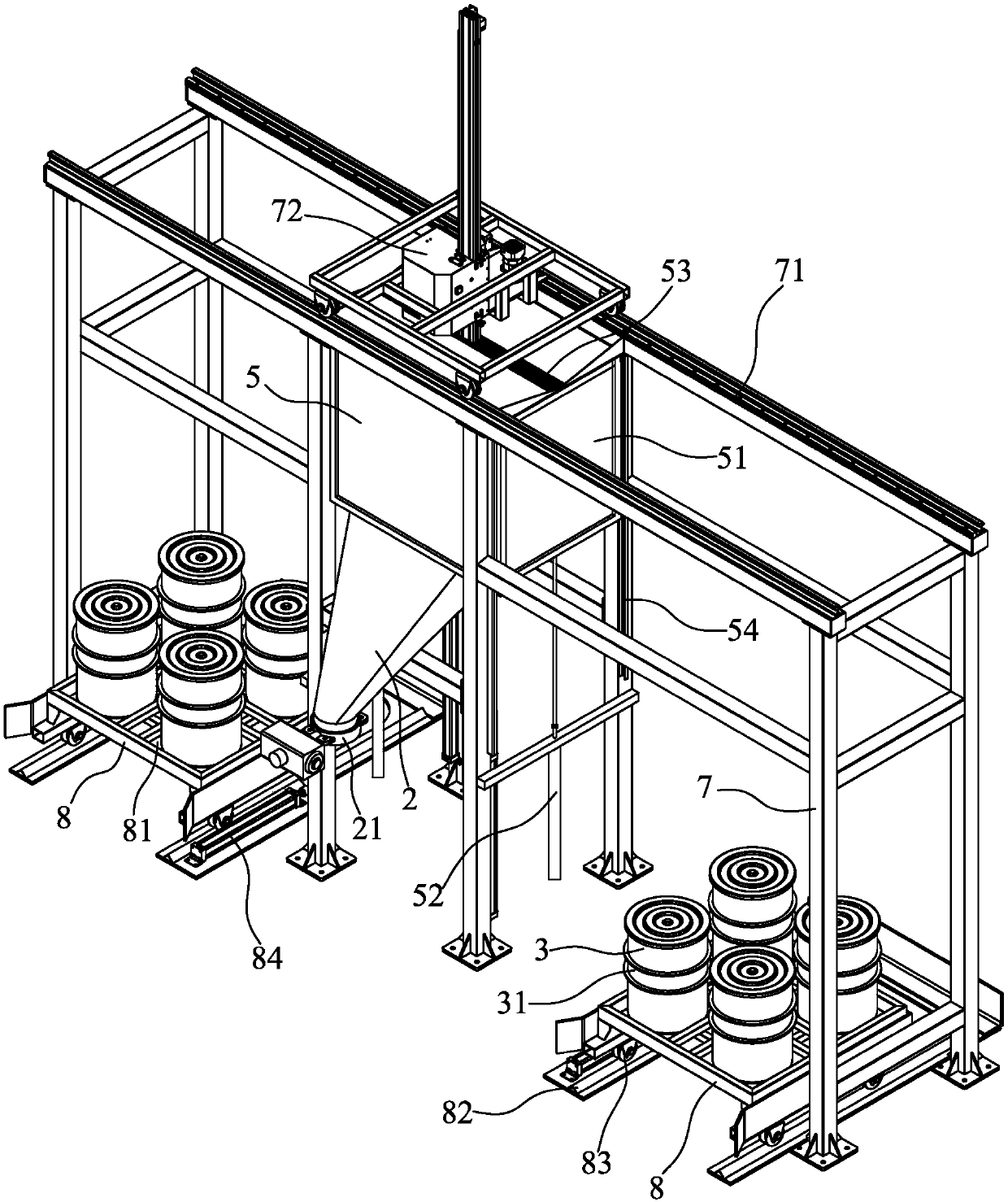

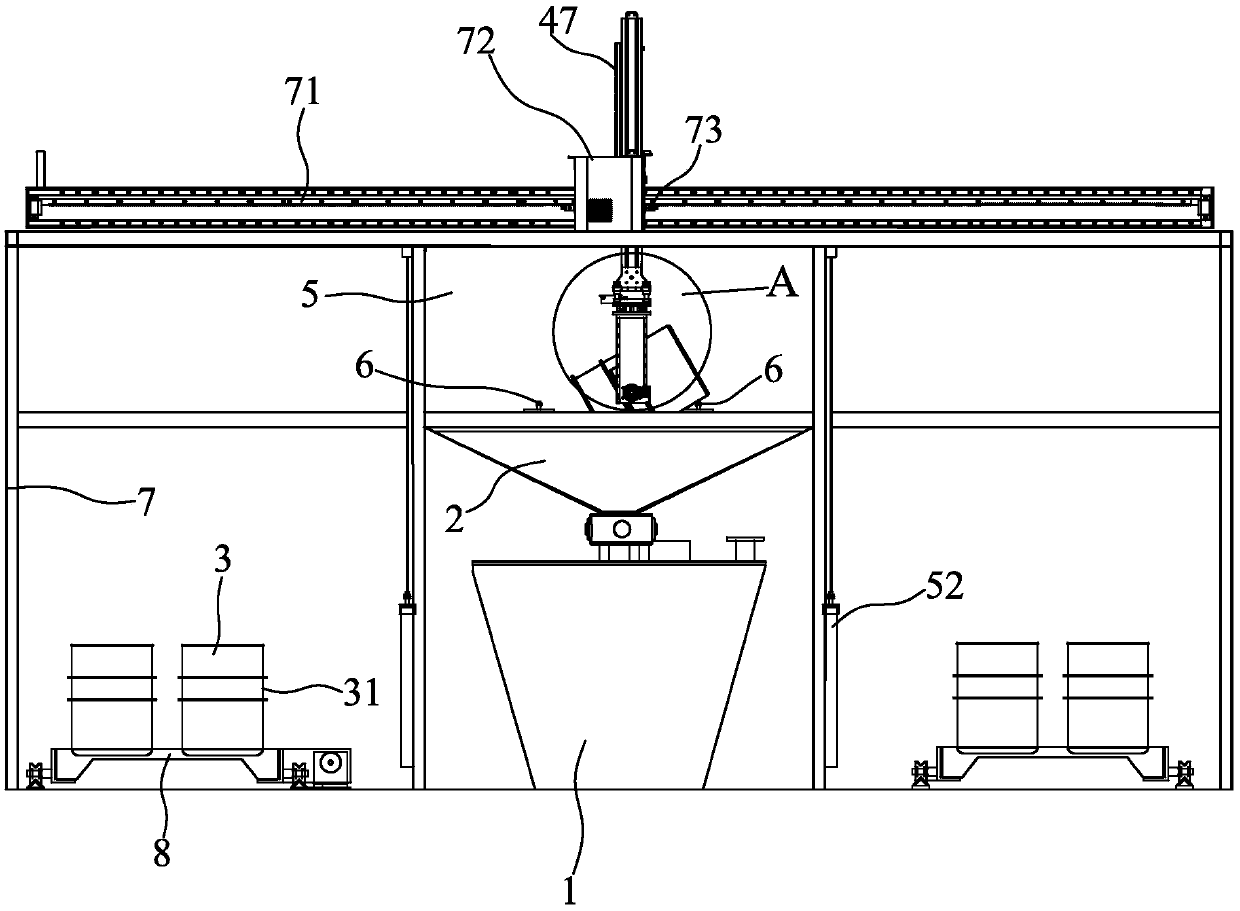

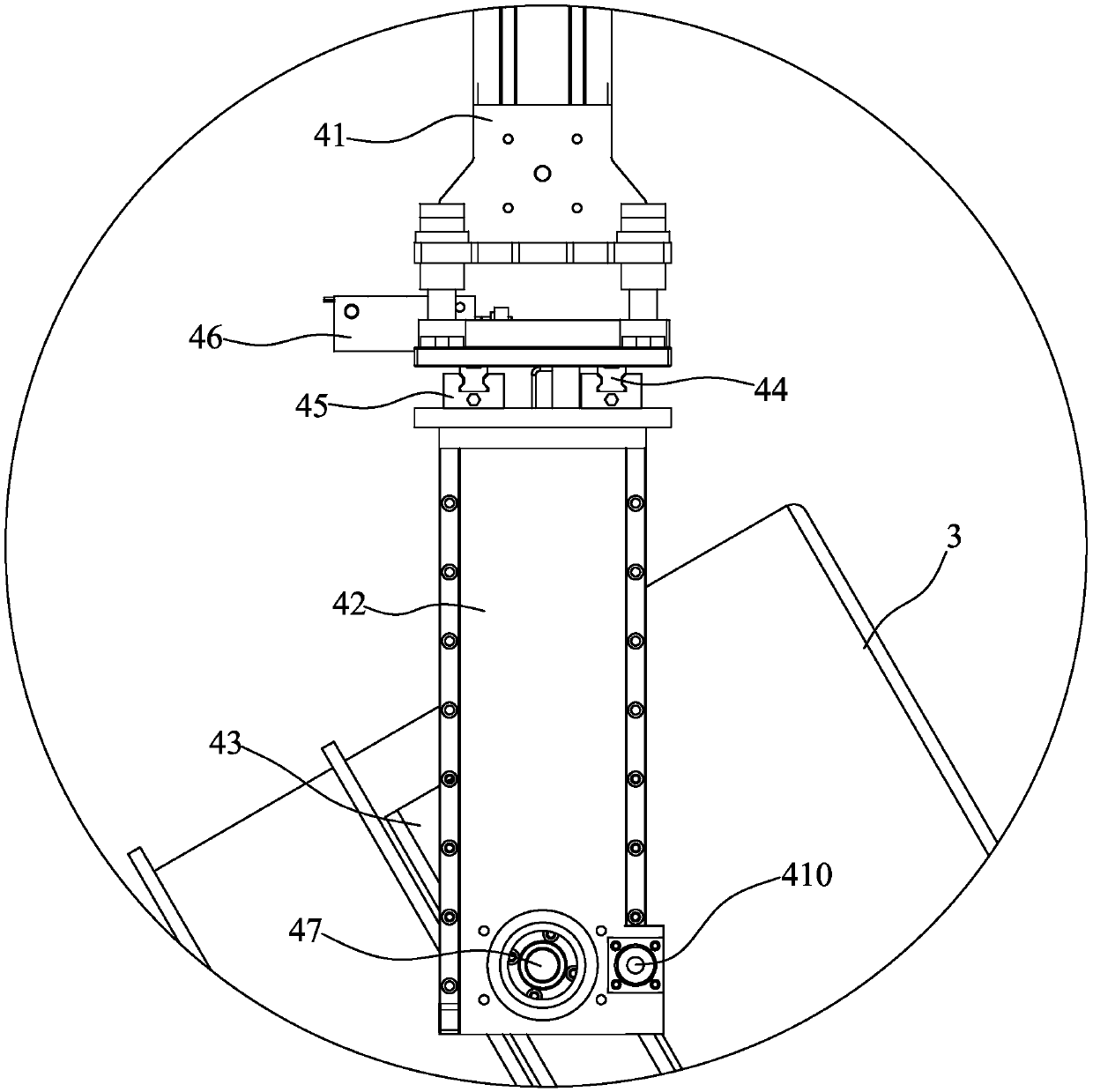

[0028] Such as Figure 1~5 Shown, a kind of lead-acid accumulator pasting device comprises pasting machine powder bin 1 and auxiliary material lower hopper 2. The discharge port at the bottom is connected to the auxiliary material feeding port of the paste machine powder bin 1, and the discharge port of the auxiliary material lower hopper 2 is provided with a pneumatic butterfly valve 21 to control the opening and closing of the discharge port.

[0029] The top of the feeding port of the auxiliary material lower hopper 2 is provided with an auxiliary material feeding chamber 5, and the bottom surface of the auxiliary material feeding chamber 5 is provided with an opening communicated with the feeding port of the auxiliary material lower hopper 2, so that the auxiliary material can be fed from the auxiliary material in the auxiliary material feeding chamber 5. The opening is added to the auxiliary material lower hopper 2, and then added to the powder bin 1 of the paste mixing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com