A fully automatic dispensing robot

A robotic and fully automatic technology, applied in coating and surface coating devices, etc., can solve problems such as difficult adjustment of dispensing volume, difficulty for operators to adapt to, high price, etc., to improve labor productivity and automation Equipping level, improving stability and repeatability, broadening the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

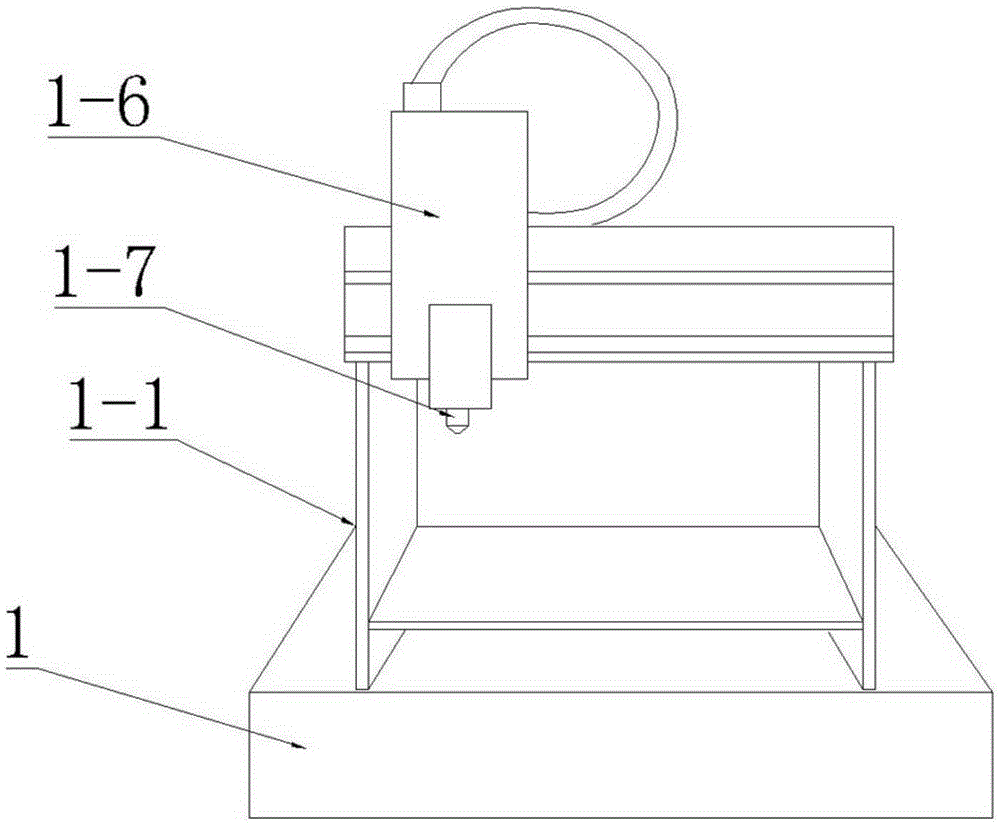

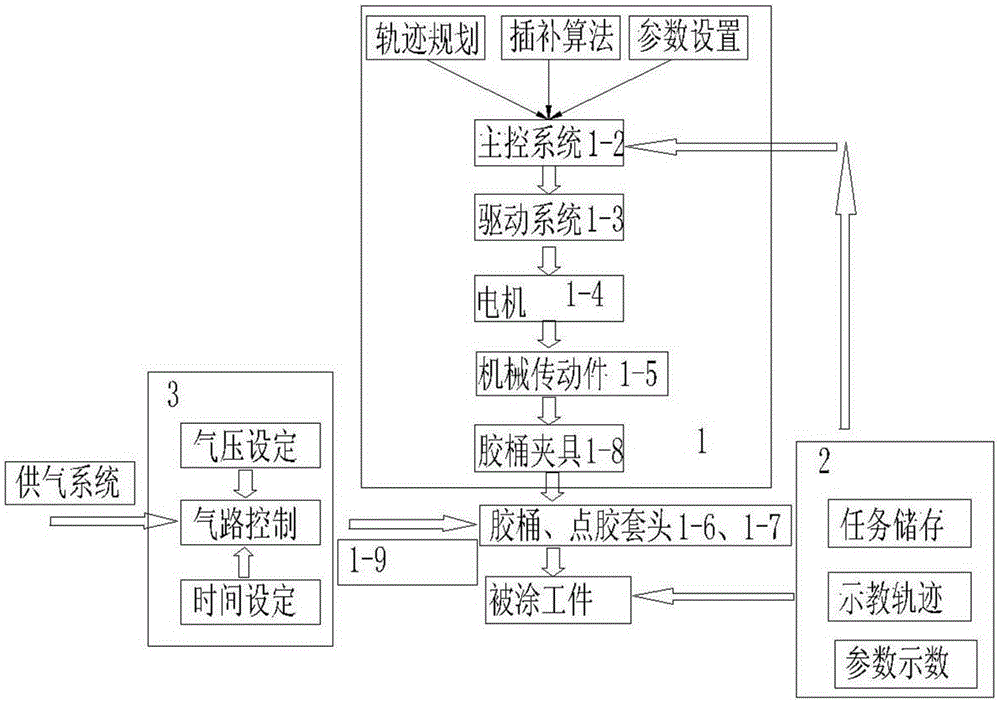

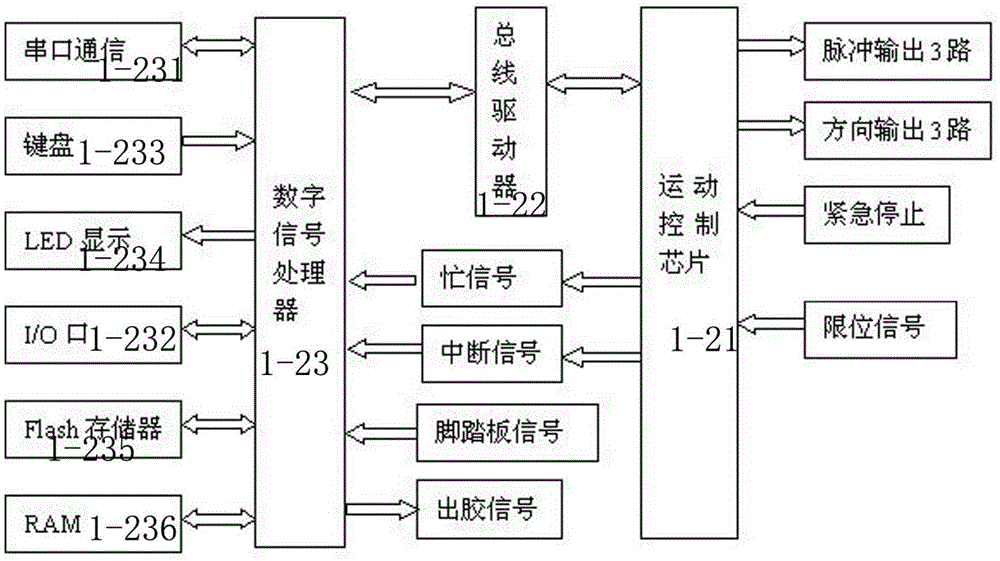

[0026] Such as Figure 1-Figure 6 Shown, a kind of fully automatic dispensing robot of the present invention, it comprises dispensing robot main frame 1, dispensing machine programmer 2 and dispensing controller 3, and dispensing robot main frame 1 comprises frame 1-1 and setting on it Main control system 1-2, drive system 1-3 connected to the output end of the main control system 1-2, mechanical transmission device 1-5 equipped with motor 1-4 driven by the drive system, equipped with dispensing sleeve 1-6 The rubber barrel 1-7, the glue barrel fixture 1-8, the mechanical transmission device 1-5 is connected to the glue barrel fixture 1-8, the glue barrel 1-7 is connected to the gas drive system 1 that drives the glue in the glue barrel to flow out of the dispensing sleeve -9, the gas drive system is connected to the dispensing controller 3 and controlled by the dispensing controller 3, and the dispensing machine programmer is connected to the signal input end of the main cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com