Automatic intelligent packaging machine for producing rubber powder on basis of waste tires

A technology of intelligent packaging and waste tires, which is applied in the direction of packaging, transportation and packaging, and the type of packaging items, can solve the problems of environmental dust pollution, waste of human resources, etc., and achieve the goal of solving dust pollution, reducing the loss rate, and improving the automation level of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

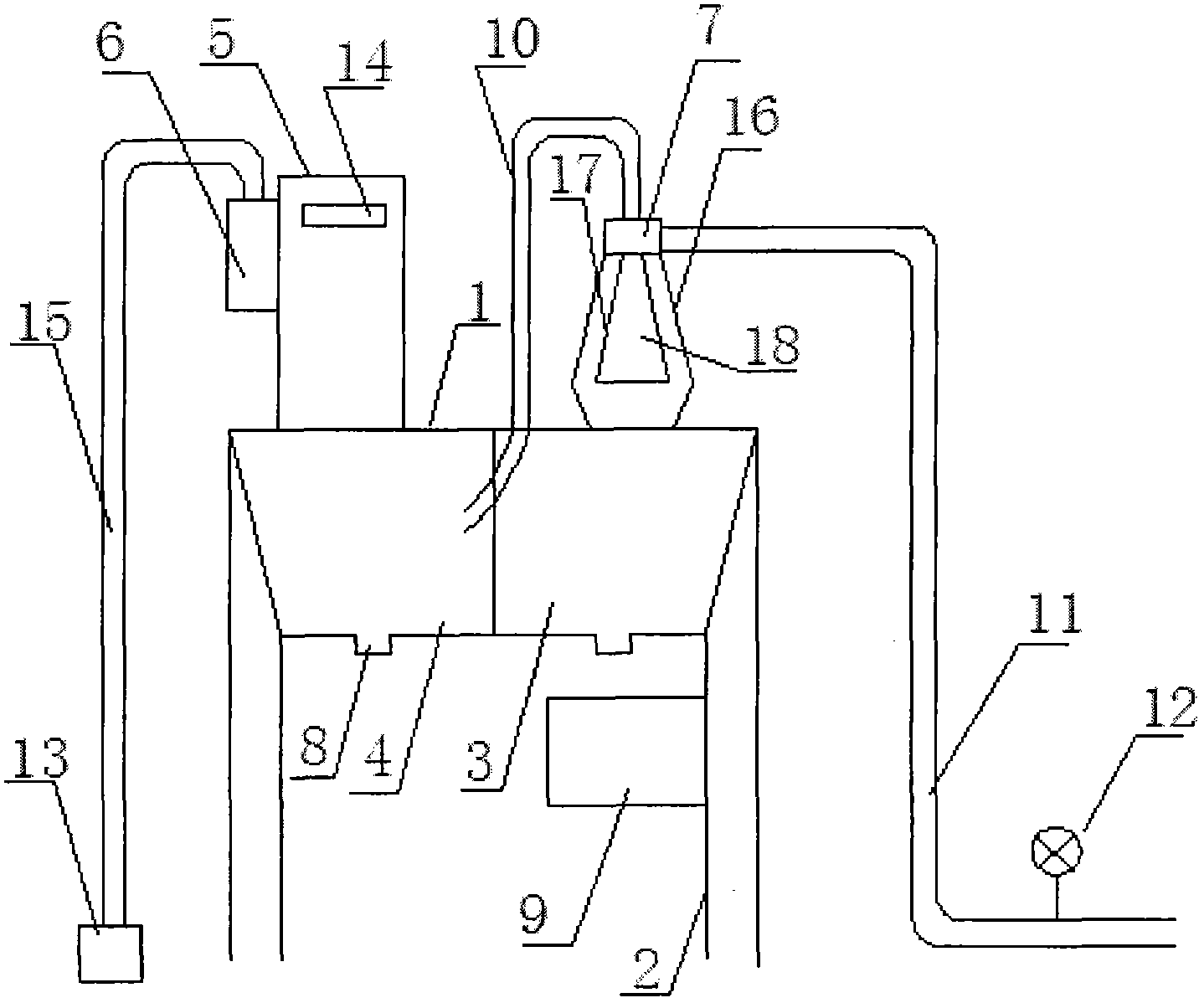

[0015] like figure 1 As shown, the automatic intelligent packaging machine for producing rubber powder from waste tires includes a storage bin 1. The storage bin 1 is a box structure with a large upper part and a small lower part. The lower part is provided with a bracket 2. The storage bin 1 is divided into left and right The storage bins are mutually sealed. The upper part of the left storage bin 4 is connected with the pulse dust collector 5 and the booster fan 6. The pulse dust collector is equipped with a blowback device 14. The upper part of the right storage bin 3 is connected with the cyclone dust collector 7; , The bottom of the right storage bin is respectively provided with a discharge port 8, and each discharge port 8 is connected with the automatic packaging machine 9 respectively, and the upper part of the cyclone dust collector 7 is connected with the dust suction pipe 10 and the rubber powder conveying pipe 11 respectively, and is connected with the The other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com