Chemiluminescence immunoassay instrument washing system with uniformly-mixing function

A chemiluminescence immunoassay and analyzer technology, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of low detection efficiency, single function, large space occupation, etc., and achieve simplified structure and high flexibility performance, and the effect of reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

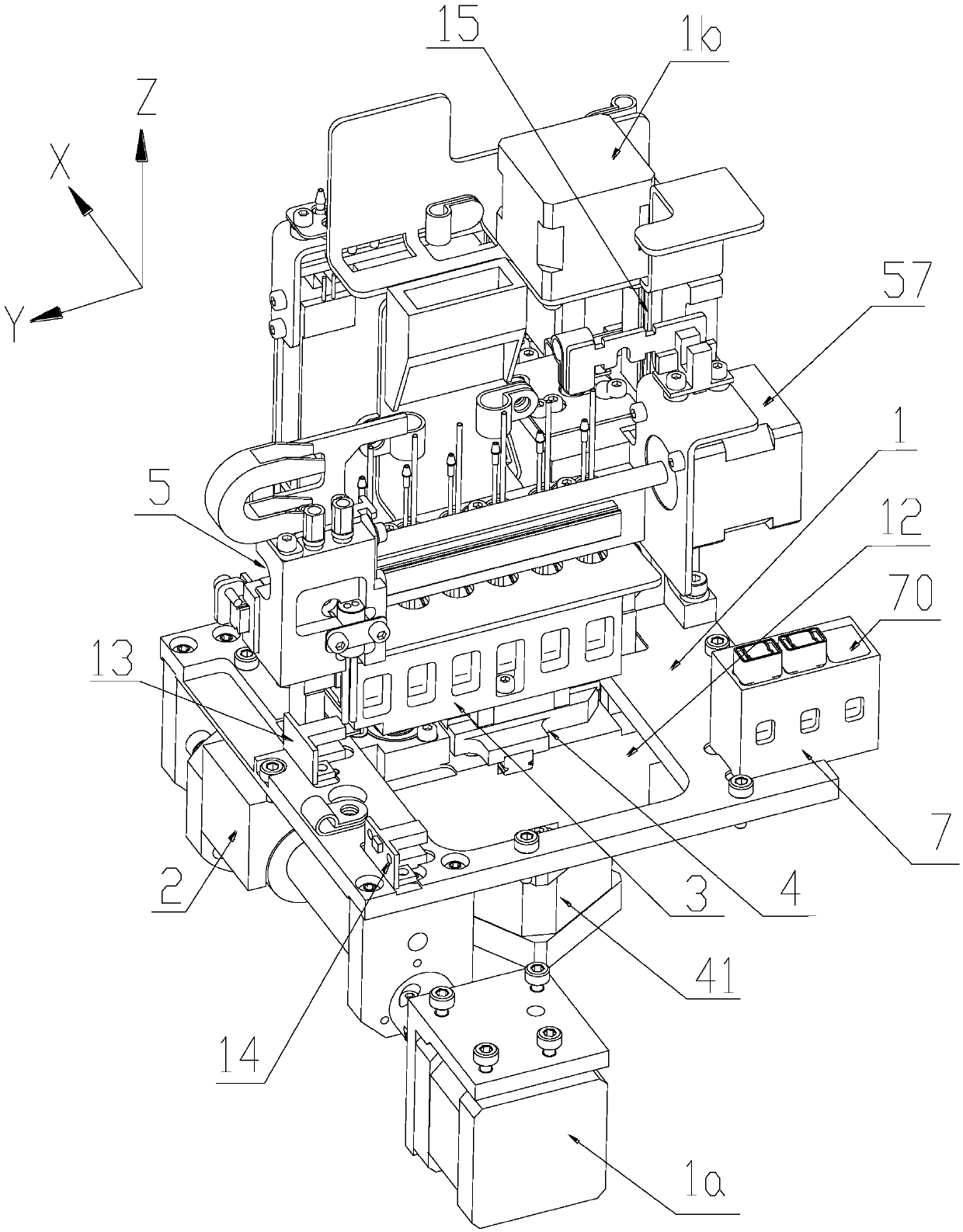

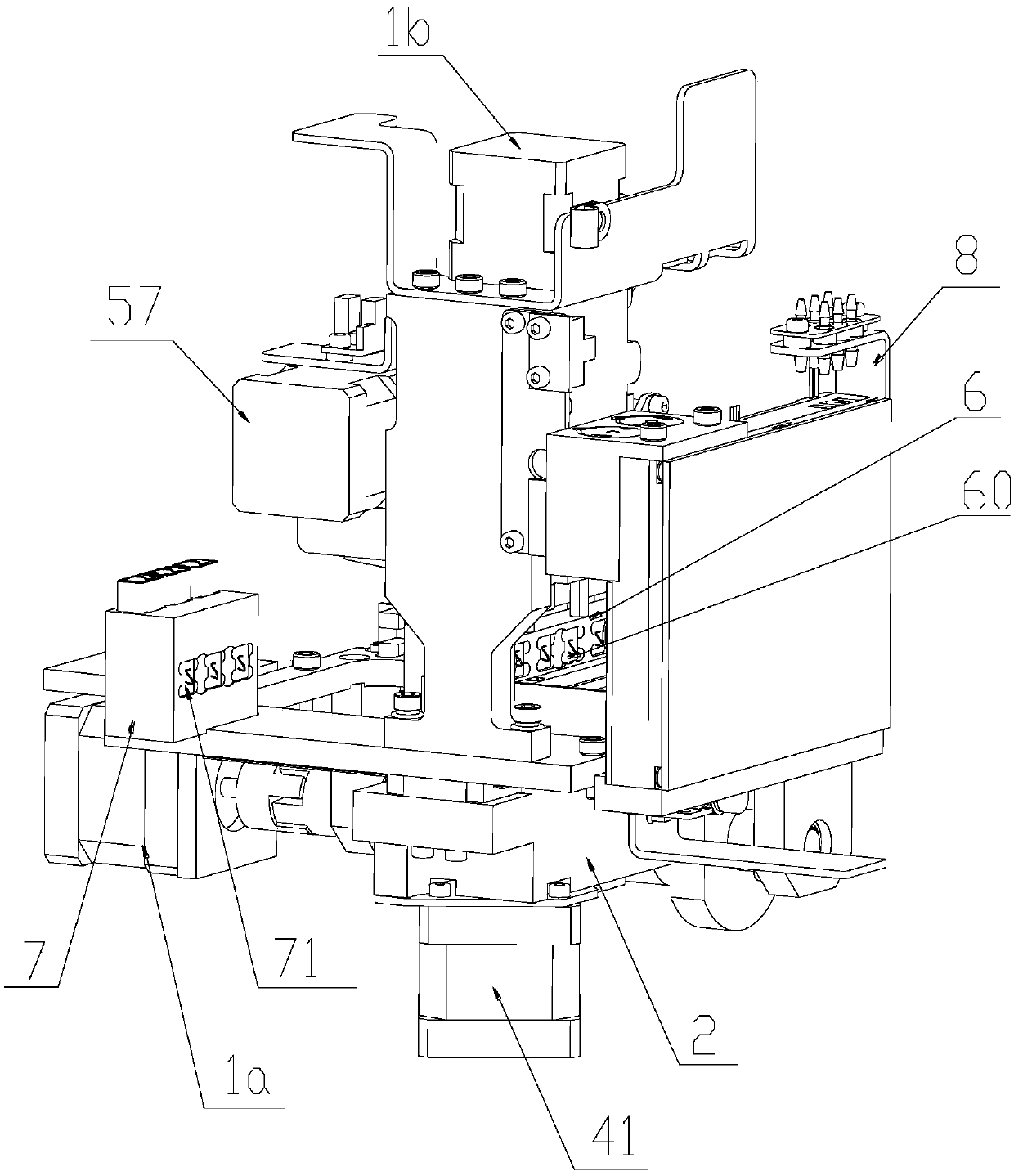

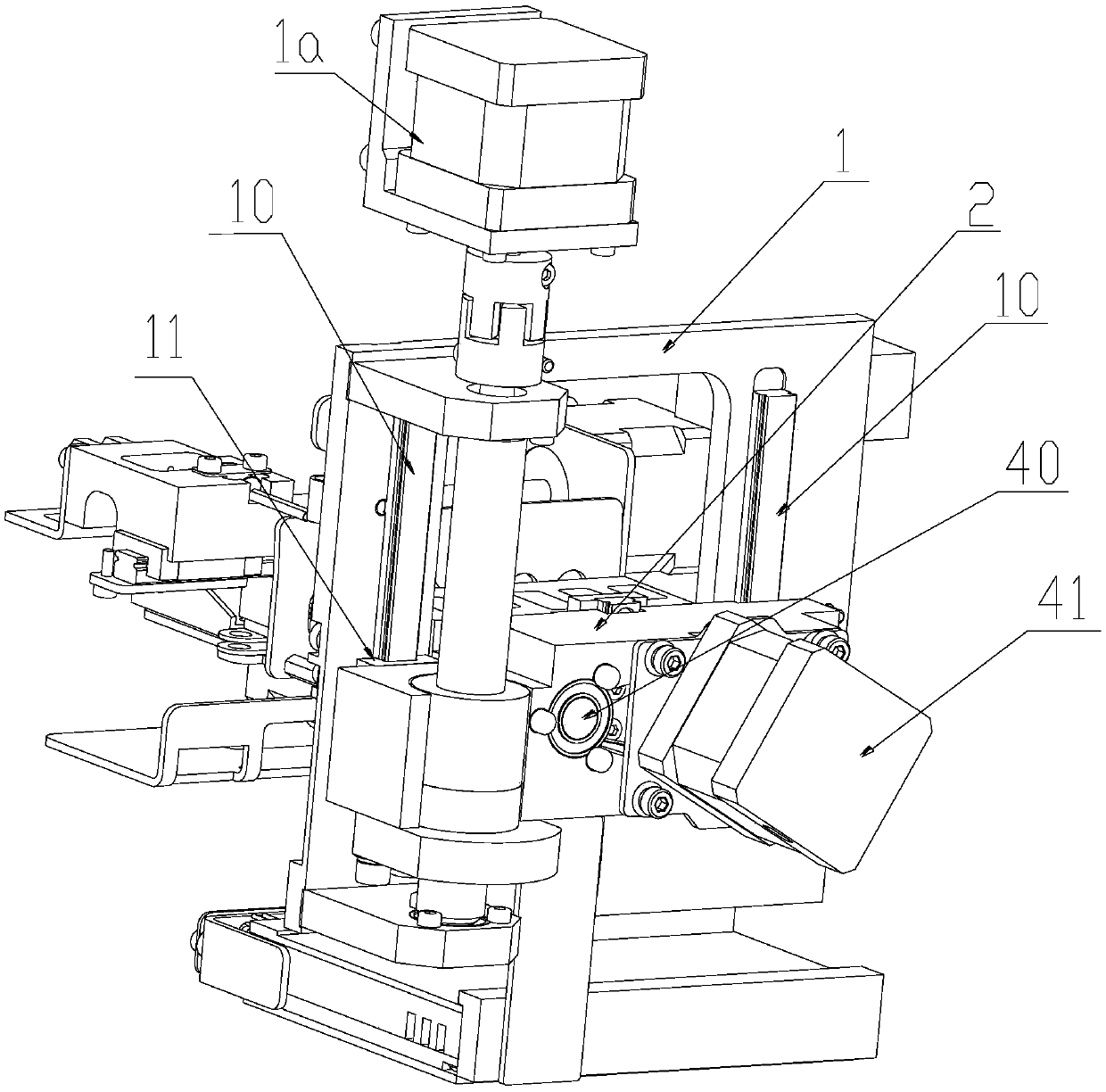

[0044] refer to Figure 1 to Figure 16 The chemiluminescence immunoassay analyzer washing system with mixing function shown in the present invention mainly includes a substrate 1 with a rectangular plate structure, and a mixing base 2 that is movably arranged on the substrate 1. In this application, mixing The base 2 can slide linearly relative to the substrate 1, and has loading and unloading positions, substrate filling positions and washing positions on its sliding stroke, and the mixing base 2 can stay in the corresponding position during the sliding process, waiting or finishing The process corresponding to the position.

[0045]The mixing base 2 is fixed with a washing cup holder 3, and the washing cup holder 3 is distributed with washing holes 30. The washing holes 30 are mainly used to place the cuvettes, and ensure the stability of the cuvettes in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com