Olefin batch polymerization technology

A polymerization process and olefin technology, which is applied in the field of olefin polymerization, can solve the problems of inconvenient polymerization operation and achieve the effects of simple equipment modification, low investment cost, and improved isotactic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

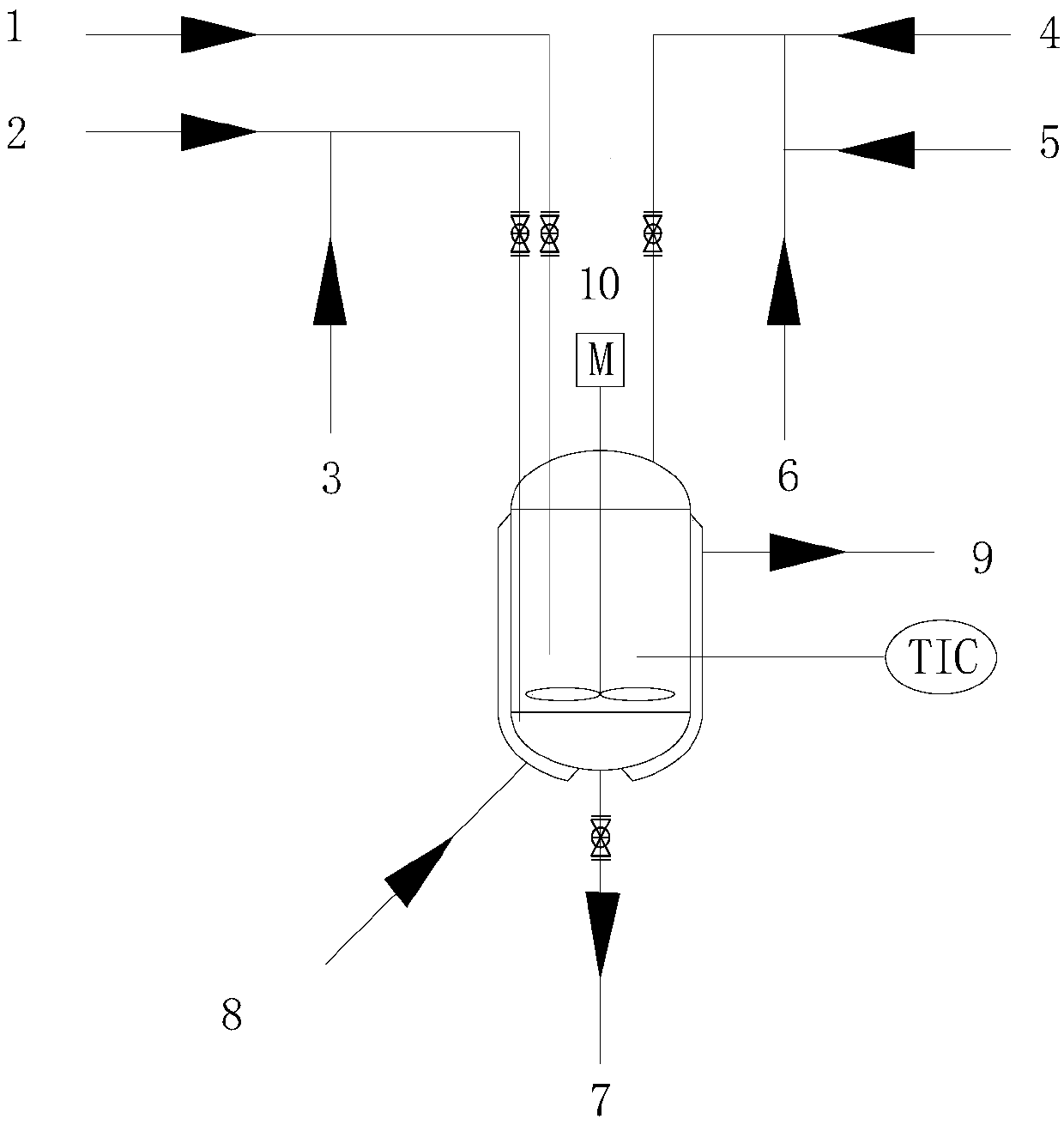

Method used

Image

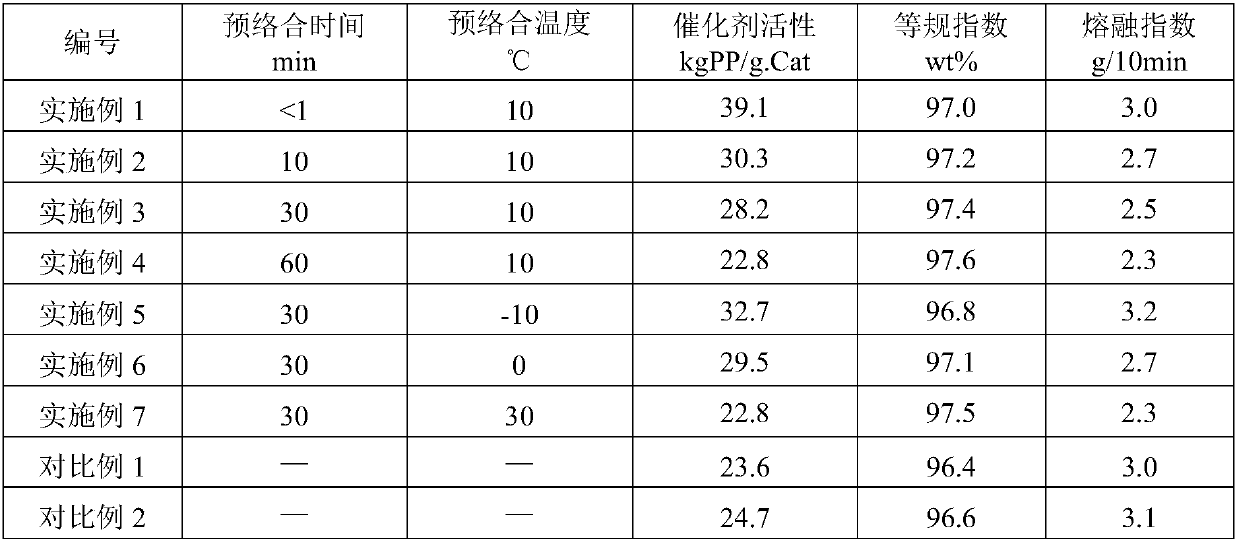

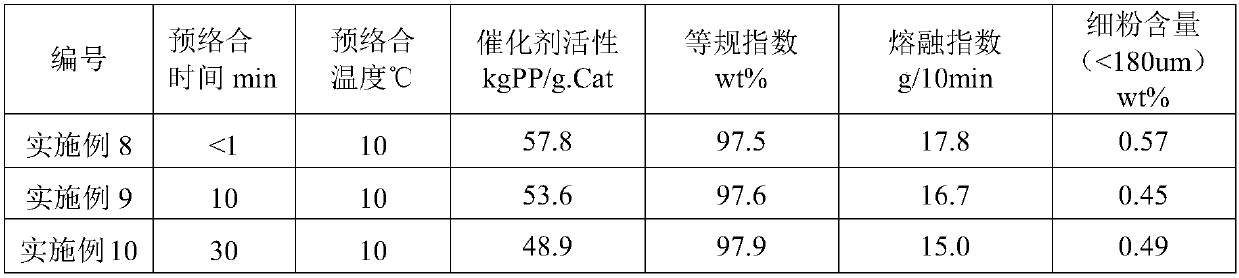

Examples

preparation example 1

[0052] This preparation example refers to the preparation method of the catalyst component of CN1718595A and the preparation method of the carrier in Example 4 to prepare the solid catalyst component A of the present invention.

[0053] In a 350mL glass reaction flask with stirring, add 50mL of hexane and 50mL of titanium tetrachloride, and cool to -20°C; add 7g of magnesium chloride alcoholate spherical particles (carrier), increase the temperature to 40°C in 5 hours, and maintain at 40°C After 0.5 hours, the liquid was filtered off; then 100mL of titanium tetrachloride and a certain amount of di-n-butyl phthalate (DNBP, DNBP / magnesium molar ratio is 1 / 8) were added, and the temperature was raised to 100°C and heated to 100°C. After maintaining the temperature for 2 hours, filter off the liquid; add 50 mL of hexane and 50 mL of titanium tetrachloride, increase the temperature to 80 ℃, and maintain at 80 ℃ for 0.5 hours, then filter off the liquid; add 100 mL of titanium tetrachlo...

preparation example 2

[0055] This preparation example refers to Example 1 of CN102838697A to prepare the solid catalyst component B of the present invention.

[0056] (1) Preparation of Dialkoxy Magnesium Carrier

[0057] After fully replacing the 16L pressure-resistant reactor with a stirrer with nitrogen, 10200 mL of ethanol and 300 mL of 2-ethylhexanol were added to the reactor, and 12 g of iodine and 8 g of magnesium chloride were added to dissolve them. After stirring, the temperature is increased until the reflux temperature of the reaction system is reached; then 640 g of magnesium powder is added successively, and the reaction is carried out until no more hydrogen is discharged. Then, it is washed, separated and dried to obtain a dry dialkoxy magnesium carrier.

[0058] (2) Preparation of solid catalyst components

[0059] Take 650g of the above-mentioned dialkoxymagnesium carrier, 3250mL of toluene, and 130mL of di-n-butyl phthalate (DNBP) to prepare a suspension for use; add 2600mL of toluene to...

Embodiment 1

[0061] This example is used to illustrate the olefin batch polymerization process of the present invention.

[0062] The catalyst is a propylene polymerization catalyst developed by China Petroleum & Chemical Corporation. Specifically, the main catalyst is the solid catalyst component A prepared in Preparation Example 1.

[0063] Operate in the pre-complexation reactor under the protection of nitrogen atmosphere, add 8mL anhydrous hexane, 5mL triethylaluminum hexane solution (concentration 0.5mmol / mL) and 1mL methylcyclohexyldimethoxy Silane in hexane solution (concentration of 0.1 mmol / mL), controlled at 200 revolutions per minute, adjusted the temperature in the pre-complexation reactor to 10°C, then added 10 mg of the main catalyst, and controlled the three-agent pre-complexation time <1min to obtain Pre-complex catalyst; then, add propylene until the pressure in the kettle rises to 0.7 MPa, and start the pre-polymerization reaction. When the pressure in the kettle drops to 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com