Preparation method of polypropylene material with high appearance performance, high performance and low emission for automobile interior and exterior decoration

A technology for automobile interior and exterior trim and polypropylene materials, which is used in the field of preparing high-performance, high-performance, low-emission polypropylene materials for automobile interior and exterior trims. Tiger skin pattern and other problems, to solve the appearance problems such as tiger skin pattern, reduce the processing temperature and solve the effect of low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

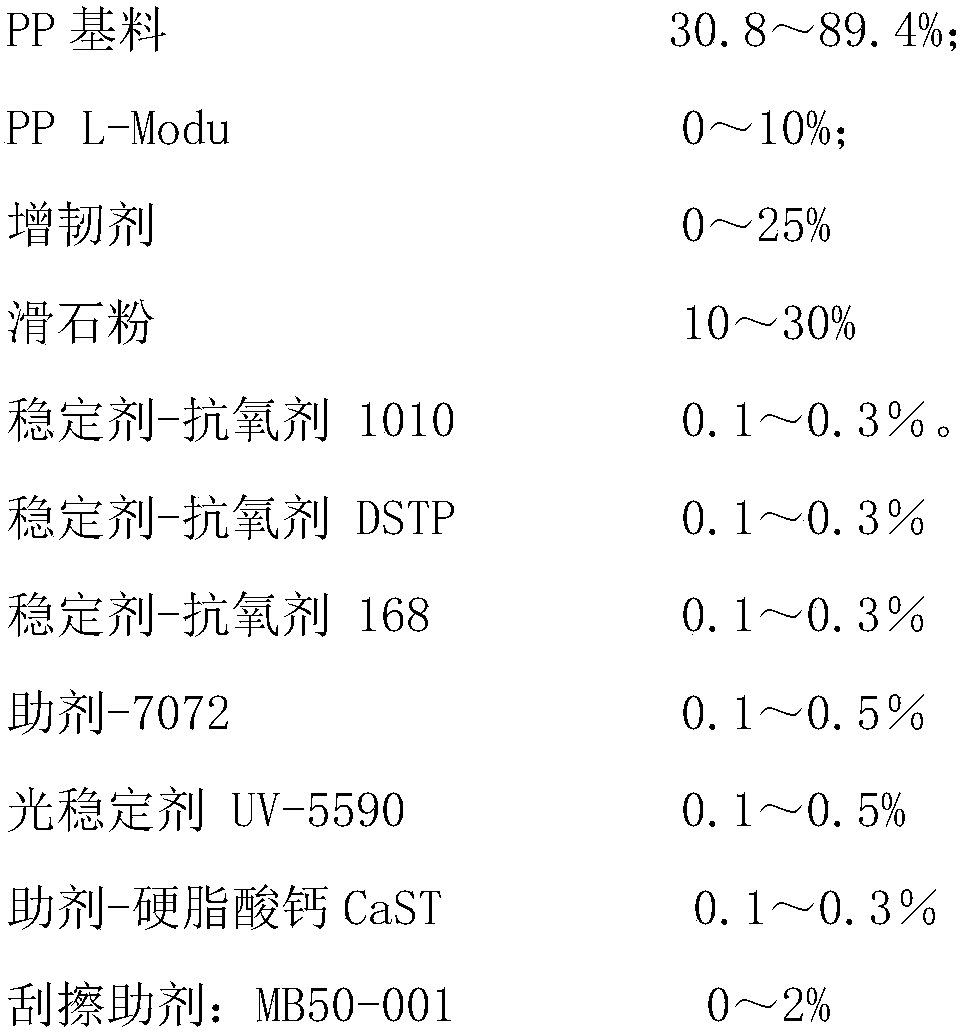

Method used

Image

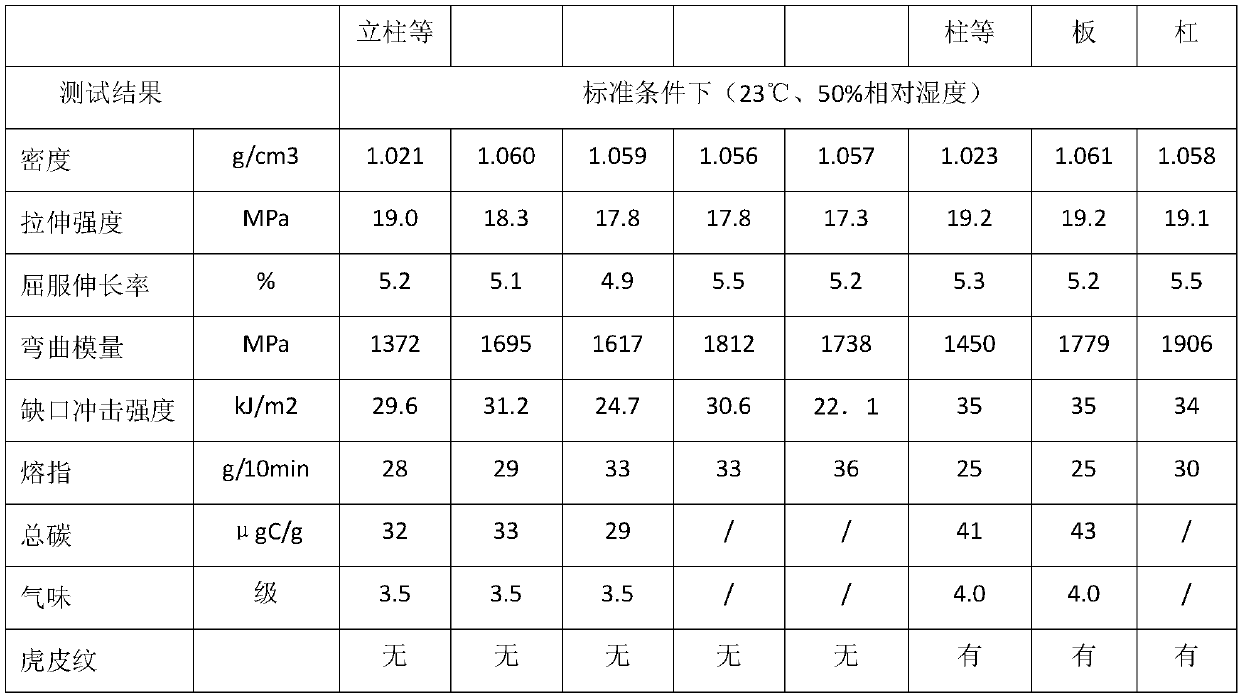

Examples

Embodiment 1

[0046] Weigh PP1 5.2kg, PP-2 1.5kg, PP L-Modu 0.5kg, talcum powder 1.5kg, toughening agent 1.5kg, antioxidant 1010 10g, antioxidant DSTP 10g, antioxidant 168 20g; - calcium stearate CaST 10g, auxiliary agent-7072 50g, light stabilizer UV-5590 20g, scraping auxiliary agent 100g; mix well in a high-speed mixer to obtain a mixture, set aside;

[0047] The above mixture is added to the twin-screw extruder (the diameter of the screw is 35 mm, and the ratio of length to diameter is L / D=40) through the main feeding port. The temperature of each section of the twin-screw extruder is controlled (from the feeding port to the head Exit) is 150°C, 210°C, 210°C, 210°C, 220°C, 220°C, 230°C, 230°C, 230°C, 230°C, head 220°C, twin-screw extruder speed is 350r / min, The extruded strips are cooled in a water tank, dried by a blower dryer, and then pelletized to obtain the product.

[0048] The above materials were dried at 100°C for 2 hours in a forced air drying oven and then injection molded i...

Embodiment 2

[0050]Weigh PP-1 1.0KG, PP2 4.18kg, PP L-Modu 0.5kg, talcum powder 2.0kg, toughening agent 1.6kg, antioxidant 1010 10g, antioxidant DSTP 10g, antioxidant 168 20g; - calcium stearate CaST 10g, auxiliary agent-707250g, light stabilizer UV-5590 20g, scraping auxiliary agent 100g; mix well in a high-speed mixer to obtain a mixture, set aside;

[0051] The above mixture is added to the twin-screw extruder (the diameter of the screw is 35 mm, and the ratio of length to diameter is L / D=40) through the main feeding port. The temperature of each section of the twin-screw extruder is controlled (from the feeding port to the head Exit) is 150°C, 210°C, 210°C, 210°C, 220°C, 220°C, 230°C, 230°C, 230°C, 230°C, head 220°C, twin-screw extruder speed is 350r / min, The extruded strips are cooled in a water tank, dried by a blower dryer, and then pelletized to obtain the product.

[0052] The above materials were dried at 100°C for 2 hours in a forced air drying oven and then injection molded in...

Embodiment 3

[0054] Weigh PP-1 1.0KG, PP2 3.68kg, PP L-Modu 1.0kg, talcum powder 2.0kg, toughening agent 1.6kg, antioxidant 1010 10g, antioxidant DSTP 10g, antioxidant 168 20g; - calcium stearate CaST 10g, auxiliary agent-707250g, light stabilizer UV-5590 20g, scraping auxiliary agent 100g; mix well in a high-speed mixer to obtain a mixture, set aside;

[0055] The above mixture is added to the twin-screw extruder (the diameter of the screw is 35 mm, and the ratio of length to diameter is L / D=40) through the main feeding port. The temperature of each section of the twin-screw extruder is controlled (from the feeding port to the head Exit) is 150°C, 210°C, 210°C, 210°C, 220°C, 220°C, 230°C, 230°C, 230°C, 230°C, head 220°C, twin-screw extruder speed is 350r / min, The extruded strips are cooled in a water tank, dried by a blower dryer, and then pelletized to obtain the product.

[0056] The above materials were dried at 100°C for 2 hours in a forced air drying oven and then injection molded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com