Polyamide-based composite material with fragrant odor and flocking imitation effect and preparation method thereof

A technology of polyamides and composite materials, which is applied in the field of polyamides, can solve problems such as unobvious types, and achieve the effect of improving compatibility, good heat resistance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

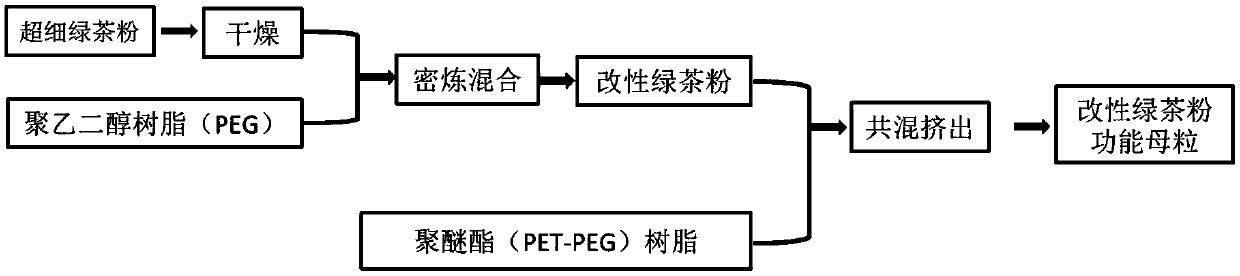

Method used

Image

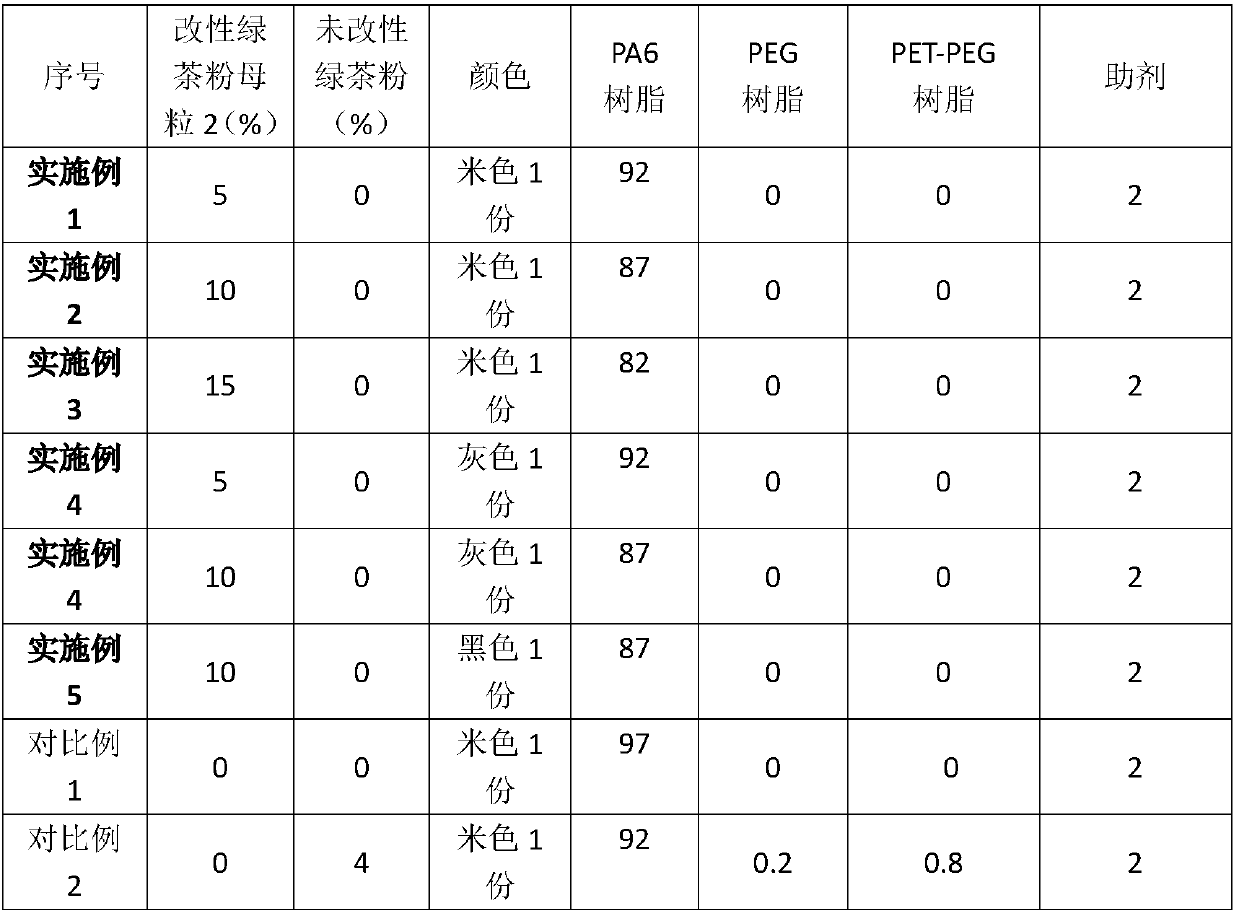

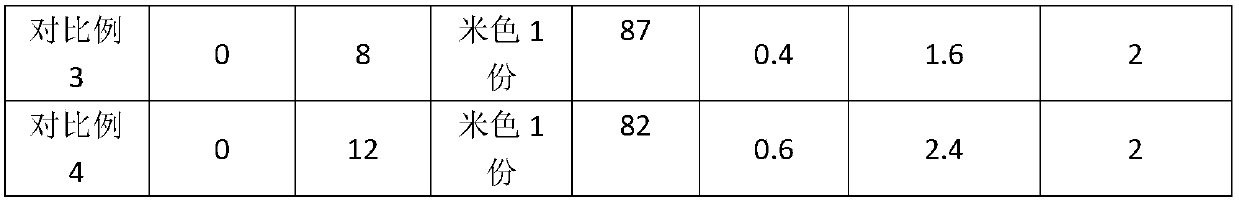

Examples

Embodiment Construction

[0033] The content of the present invention will be further elaborated below in conjunction with specific embodiments. It should be emphasized that these examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. In addition, it should be understood that after reading the contents of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0034] Concrete embodiment 1~5 and corresponding comparative example 1~2 adopt raw material and preparation technology as follows:

[0035] Raw materials:

[0036] Polyamide resin: PA6 resin, commercially available;

[0037] Unmodified green tea powder: it is a green tea powder with an average particle diameter of 150um, commercially available;

[0038] Surface treatment ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com