UV fast curing optical fiber coloring ink and preparation method thereof

A coloring ink, fast curing technology, applied in the direction of ink, household appliances, applications, etc., can solve the problem of unable to meet the requirements of optical fiber coloring ink, and achieve the effect of fast curing speed, high surface smoothness, and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

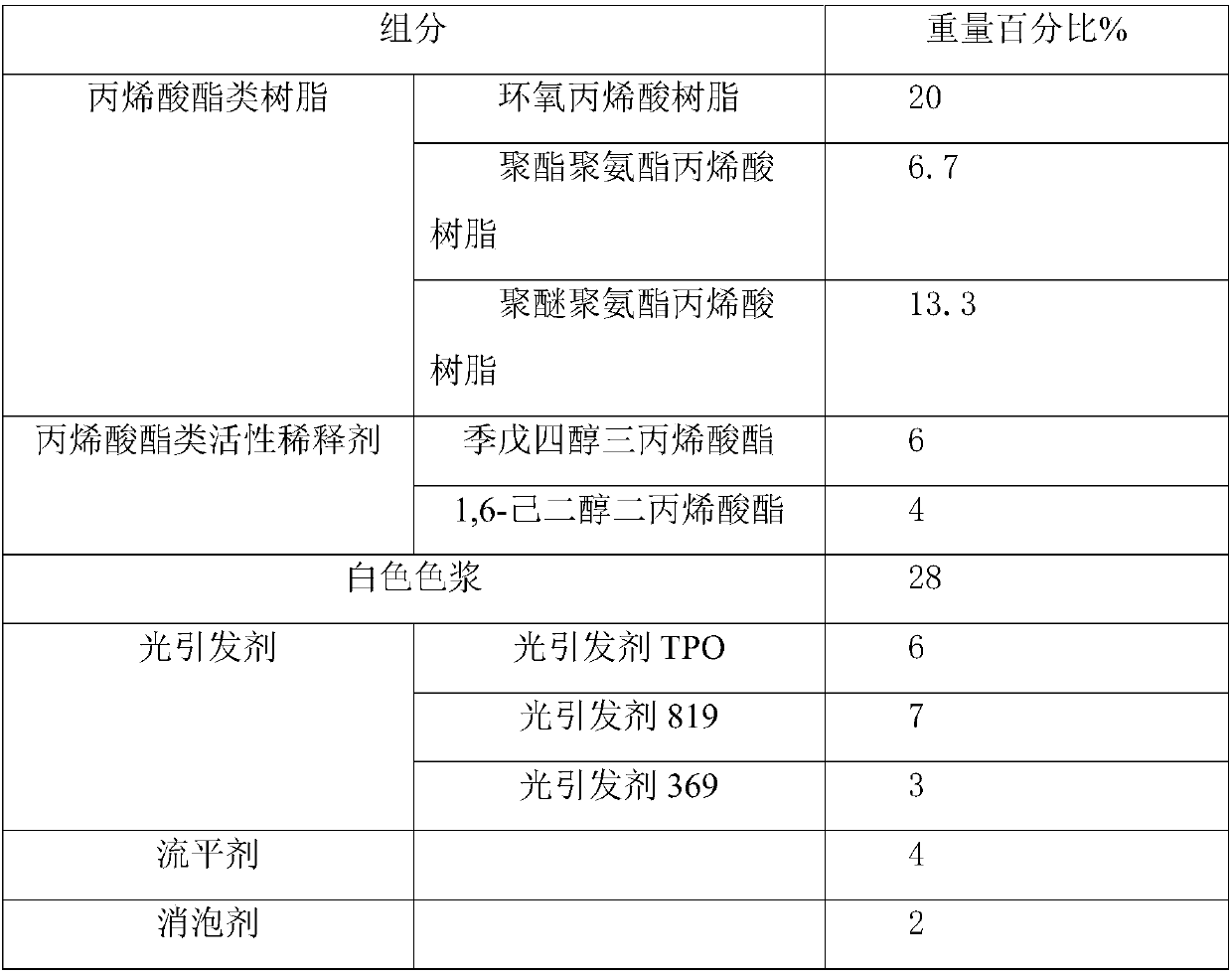

[0047] This embodiment provides a UV fast-curing optical fiber white ink. The composition and preparation method of the ink are as follows:

[0048]

[0049] The above raw materials were fully stirred at 60°C for 2.5 hours, and after the photoinitiator was completely dissolved, they were filtered to obtain a UV fast-curing optical fiber white ink.

[0050] The viscosity of the optical fiber white ink prepared in this example is 3500cps (25°C), the average particle size is 0.65um, and it is placed at room temperature for seven days without sedimentation. After UV curing, the double bond conversion rate of the optical fiber white ink is 86%. Higher, butanone wipes 50 times without fading, strong tinting power, dynamic friction coefficient of 0.080, and high surface smoothness.

Embodiment 2

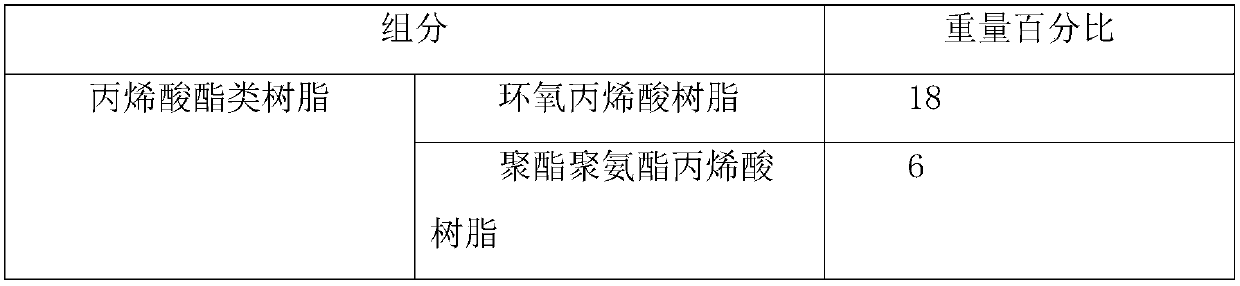

[0052] This embodiment provides a UV fast-curing optical fiber blue ink, the composition and preparation method of the ink are as follows:

[0053]

[0054]

[0055] The above raw materials were fully stirred at 60°C for 2.5 hours, and after the photoinitiator was completely dissolved, they were filtered to obtain UV fast-curing optical fiber blue ink.

[0056] The optical fiber blue ink prepared in this example has a viscosity of 2880cps (25°C), an average particle size of 0.60um, and placed at room temperature for seven days without sedimentation. After UV curing, the double bond conversion rate of the optical fiber blue ink is 87%. High curing degree, no fading after 50 times of butanone wiping, strong tinting strength, dynamic friction coefficient 0.075, and high smoothness of the surface.

Embodiment 3

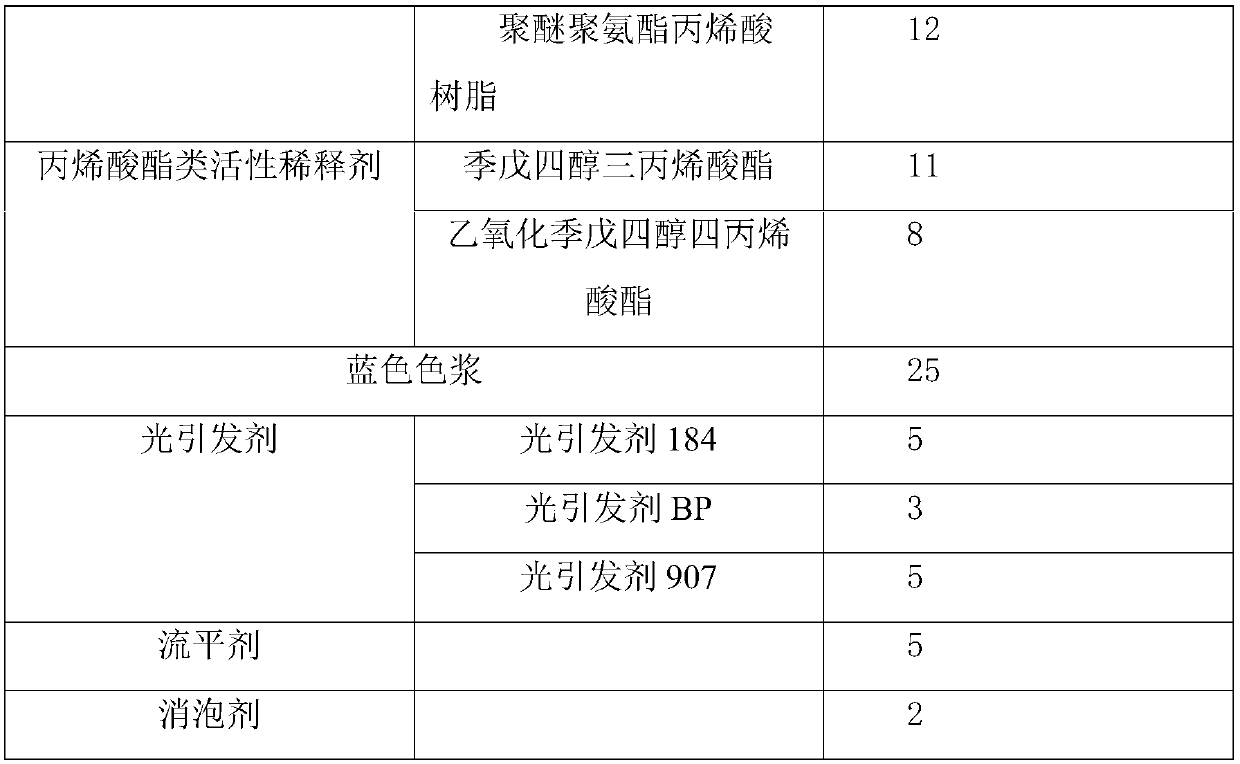

[0058] This embodiment provides a UV fast-curing optical fiber green ink, the composition and preparation method of the ink are as follows:

[0059]

[0060]

[0061] The above raw materials were fully stirred at 60°C for 2.5 hours, and after the photoinitiator was completely dissolved, they were filtered to obtain UV fast-curing fiber optic green ink.

[0062] The fiber optic green ink prepared in this example has a viscosity of 3325cps (25°C), an average particle size of 0.50um, and is placed at room temperature for seven days without sedimentation. After UV curing, the double bond conversion rate of the fiber optic green ink is 83.5%. Higher, butanone wipes 50 times without fading, strong tinting power, dynamic friction coefficient of 0.065, and high surface smoothness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com