Silicon rubber insulation self-adhesive tape for electrical equipment and preparation method of silicon rubber insulation self-adhesive tape

A technology of silicone rubber insulation and electrical equipment, applied in the field of coatings, can solve the problems of not being able to detect local overheating of electrical equipment in time, and achieve the effects of reducing overheating, facilitating heat dissipation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

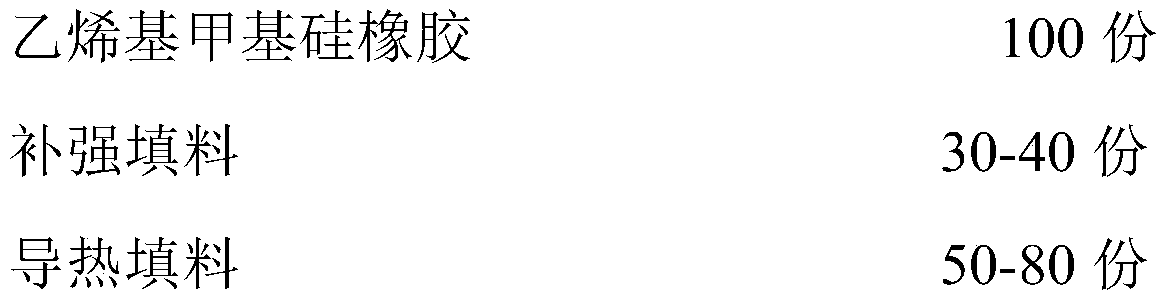

[0030] The raw material composition of silicone rubber insulating self-adhesive tape used in electrical equipment is as follows:

[0031]

[0032]

[0033] A preparation method of silicone rubber insulating self-adhesive tape applied to electrical equipment: step a: adding vinyl methyl silicone rubber into a kneader, and then sequentially adding hydrophobic fumed silica, zinc oxide, hydroxyl silicone oil, and NP-430 , methylmercapto silicone oil, polymethylborosiloxane and temperature-indicating pigments are kneaded for 2-3 hours; step b: knead the kneaded material on the rubber mixer for 15 minutes; step c: formulate the corresponding specifications on the tablet machine Sheet tape; step d: vulcanize the prepared sheet tape by electron accelerator radiation to obtain a silicone rubber insulating self-adhesive tape for electrical equipment.

Embodiment 2

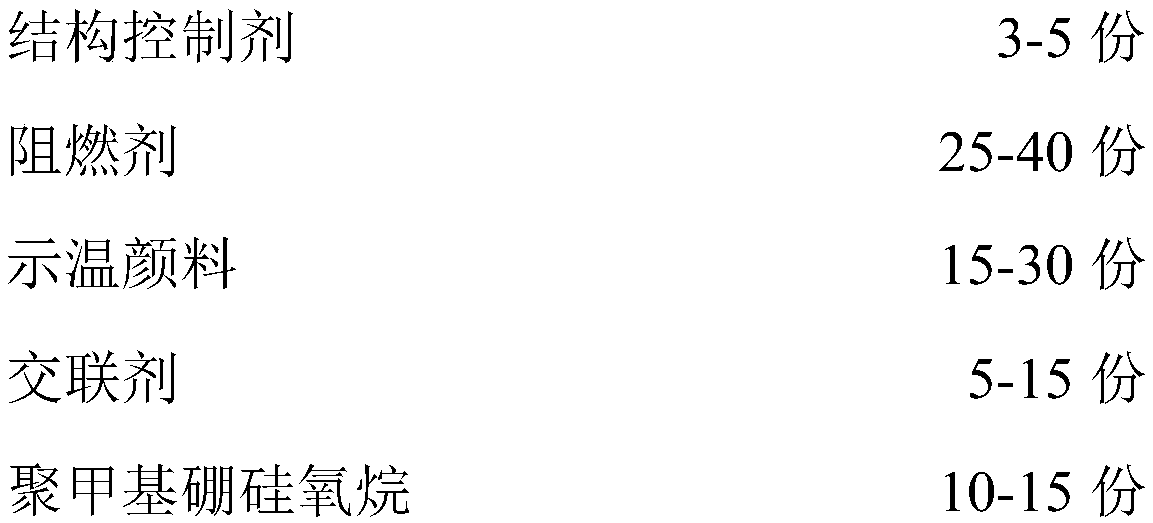

[0035] The raw material composition of silicone rubber insulating self-adhesive tape used in electrical equipment is as follows:

[0036]

[0037] A preparation method of silicone rubber insulating self-adhesive tape applied to electrical equipment: step a: adding vinyl methyl silicone rubber into a kneader, and then sequentially adding hydrophobic fumed silica, zinc oxide, hydroxyl silicone oil, and composite ceramic Knead powder, methylmercapto silicone oil, polymethylborosiloxane and temperature-indicating pigment for 2-3 hours; step b: knead the kneaded material on the rubber mixer for 15 minutes; step c: formulate the corresponding specifications on the tablet machine The sheet tape; step d: vulcanize the prepared sheet tape by electron accelerator radiation to obtain a silicone rubber insulating self-adhesive tape for electrical equipment.

Embodiment 3

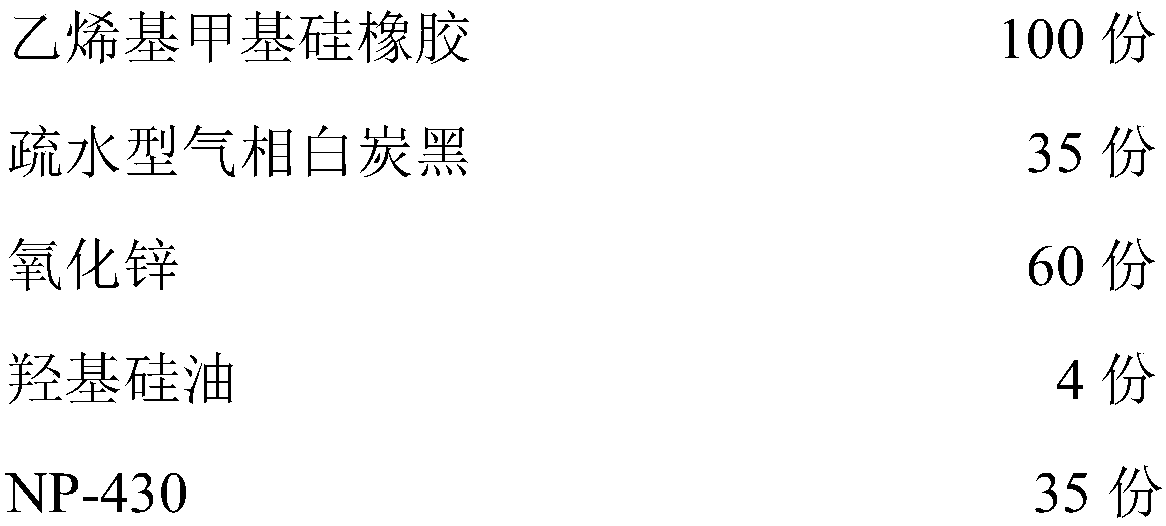

[0039] The raw material composition of silicone rubber insulating self-adhesive tape used in electrical equipment is as follows:

[0040]

[0041] A preparation method of a silicone rubber insulating self-adhesive tape applied to electrical equipment: step a: adding vinyl methyl silicone rubber into a kneader, and then sequentially adding hydrophobic fumed silica, zinc oxide, and dihydroxydiphenylsilane , NP-430, methylmercapto silicone oil, polymethylborosiloxane and temperature-indicating pigments were kneaded for 2-3 hours; step b: knead the kneaded materials on the rubber mixer for 15 minutes; step c: formulate on the tablet machine produce a strip of corresponding specification; step d: vulcanize the prepared strip by electron accelerator irradiation, and obtain a silicone rubber insulating self-adhesive tape for electrical equipment.

[0042] The performance test data of the silicone rubber insulating self-adhesive tape applied to electrical equipment prepared in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com