Electric-driven speed changing device integrating heat dissipation, lubricating and electrically-controlled brake

A technology of speed change device and electric control brake, which is applied in the direction of electromechanical device, transmission device parts, brake parts, etc., can solve the problems of inability to realize integrated hoisting, occupy large volume, and have many connection interfaces, and achieve compact structure and workability. Safe and reliable, the effect of reducing failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

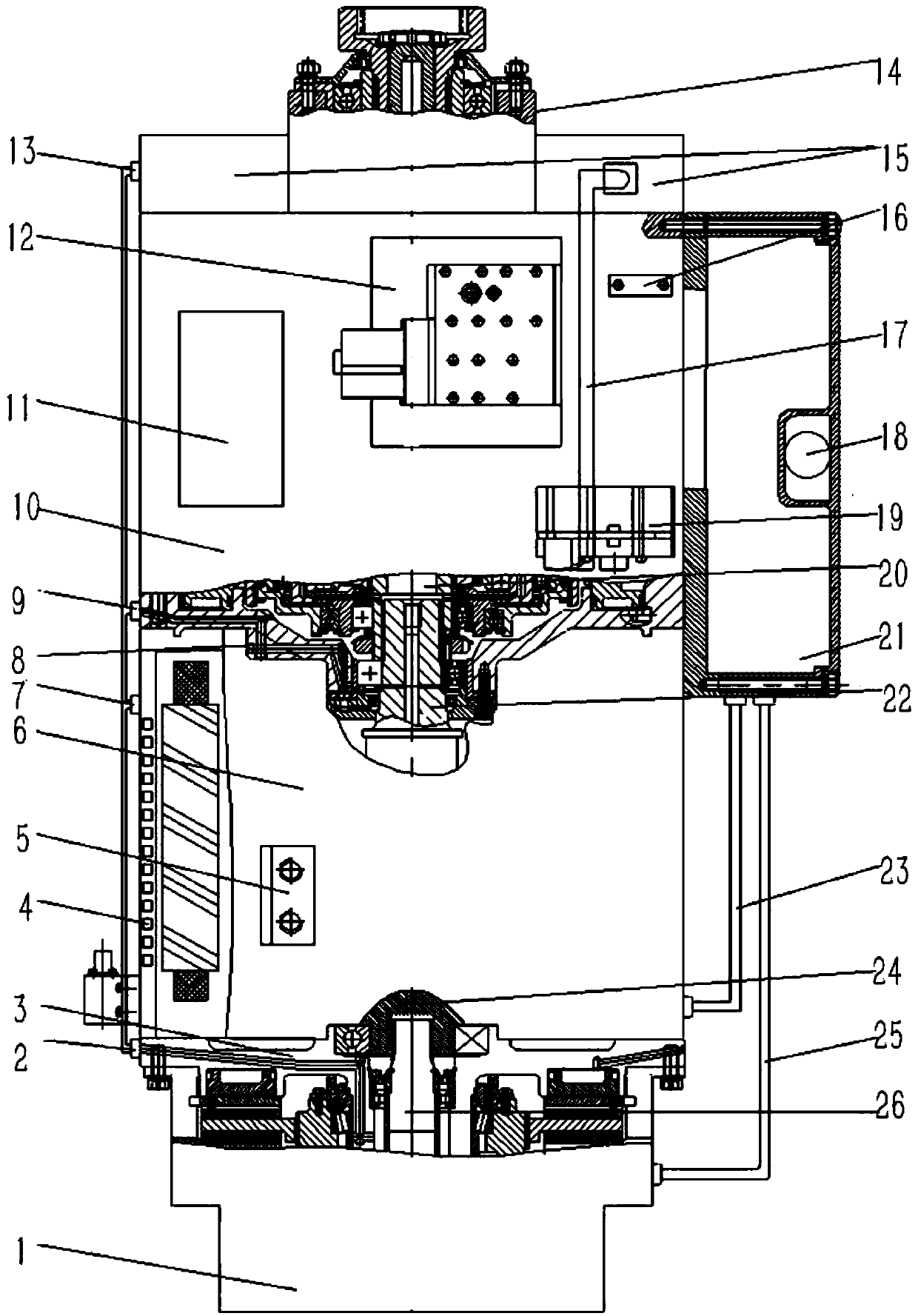

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

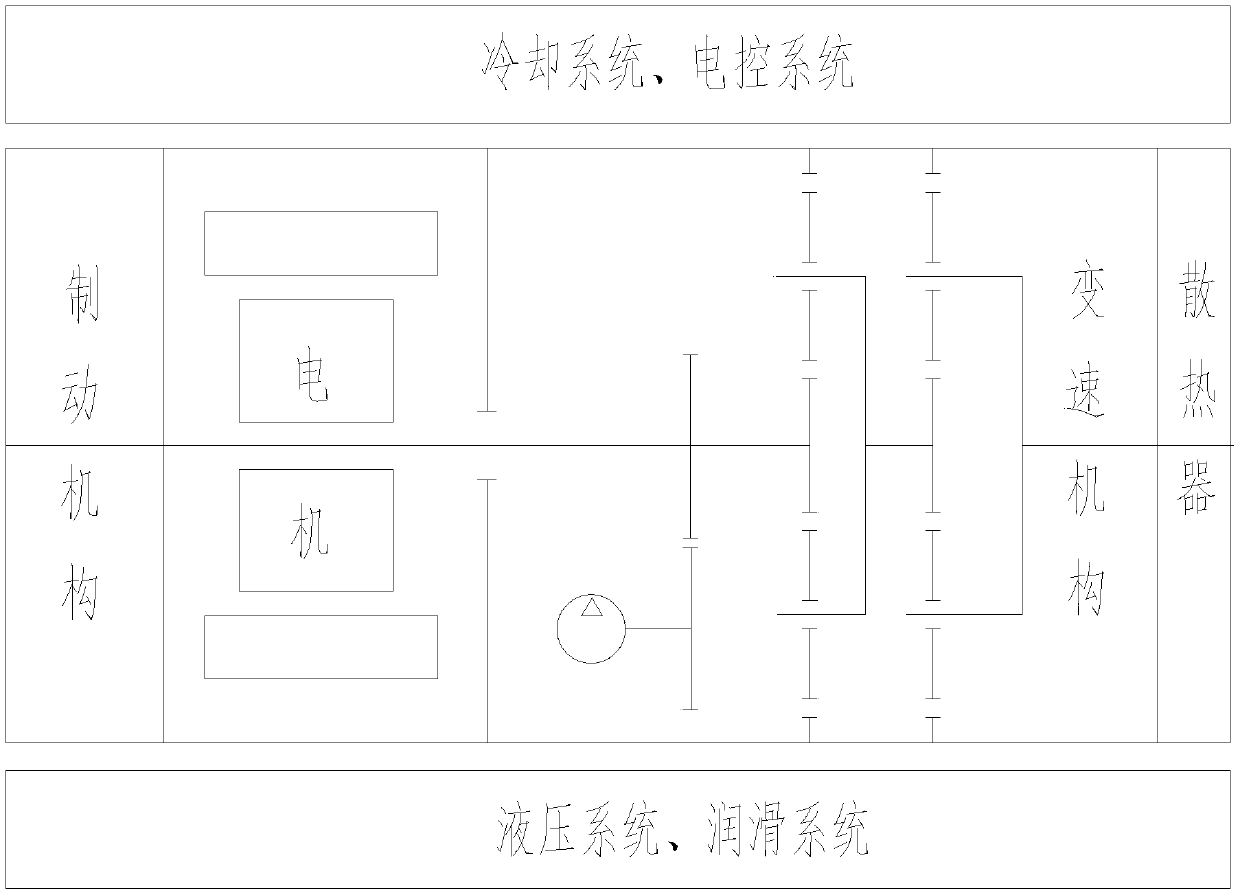

[0023] Such as Figure 1-2 As shown, the specific structure of the present invention is: an electric drive speed change device integrating heat dissipation, lubrication, electric control and braking, including a motor 6, a speed change mechanism 10, a brake mechanism 1, a radiator 15, an electric control system 11, a hydraulic pressure system and lubricating system, the brake mechanism 1 is arranged at the end of the motor 6, the brake mechanism transmission shaft 26 on the brake mechanism 1 is connected to the motor tail shaft 24 through transmission, and the brake at the end of the brake mechanism 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com