A kind of preparation method of glass light guide plate

A glass light guide plate and glass substrate technology, applied in the field of light guide plates, can solve the problems of differences in chemical properties between ink and glass, unfavorable mass production, poor ink adhesion, etc., to avoid micro-cracks on the glass surface, good dot effect, and good The effect of glass strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]The preparation method of the glass light guide plate, including the steps of:

[0023]1) Use deionized water to clean the glass substrate, then heat drying;

[0024]2) Use the tempered glass production line to heat the glass substrate to 600 ° C, which is in a semi-melted state, and one of the planes as a mesh;

[0025]3) Set the laser point equipment in the heating zone of the tempered glass production line, and the network point is in half-melting state, the laser point equipment has a procedure corresponding to the outlet pattern, and the laser point is performed directly at the outlet to form the concave edge of the mesh. Outlet;

[0026]4) Enter the glass substrate into the cooling zone cooling below, that is, the glass light guide plate is obtained.

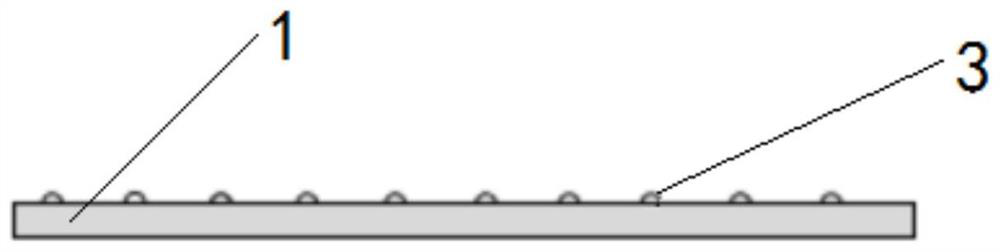

[0027]Such asfigure 1 As shown, a structural schematic view of the glass light guide plate of the present embodiment, including a glass substrate 1 and a concave network point 2 on the surface of the glass substrate 1.

Embodiment 2

[0029]The preparation method of the glass light guide plate, including the steps of:

[0030]1) Clean the glass substrate using ethanol, then dry;

[0031]2) Heat the glass substrate to 650 ° C by the tempered glass production line, which is in a semi-melted state, one of which is the mesh surface;

[0032]3) Set the laser point equipment in the heating zone of the tempered glass production line, and the network point is in half-melting state, the laser point equipment has a procedure corresponding to the outlet pattern, and the laser point is performed directly at the outlet to form the concave edge of the mesh. Outlet;

[0033]4) Enter the glass substrate into the cooling zone cooling below, that is, the glass light guide plate is obtained.

Embodiment 3

[0035]The preparation method of the glass light guide plate, including the steps of:

[0036]1) Use deionized water to clean the glass substrate, then heat drying;

[0037]2) Use the tempered glass production line to heat the glass substrate to 700 ° C, which is in a semi-melted state, and one of the planes as a mesh;

[0038]3) Set the laser point device in the heating zone discharge opening of the tempered glass production line, and the network point surface is in a semi-melted state, the laser point device has a program corresponding to the network point pattern, and the area other than the network point is etched by laser. Oreal, forming outlets convex along the surface of the mesh;

[0039]4) Enter the glass substrate into the cooling zone cooling below, that is, the glass light guide plate is obtained.

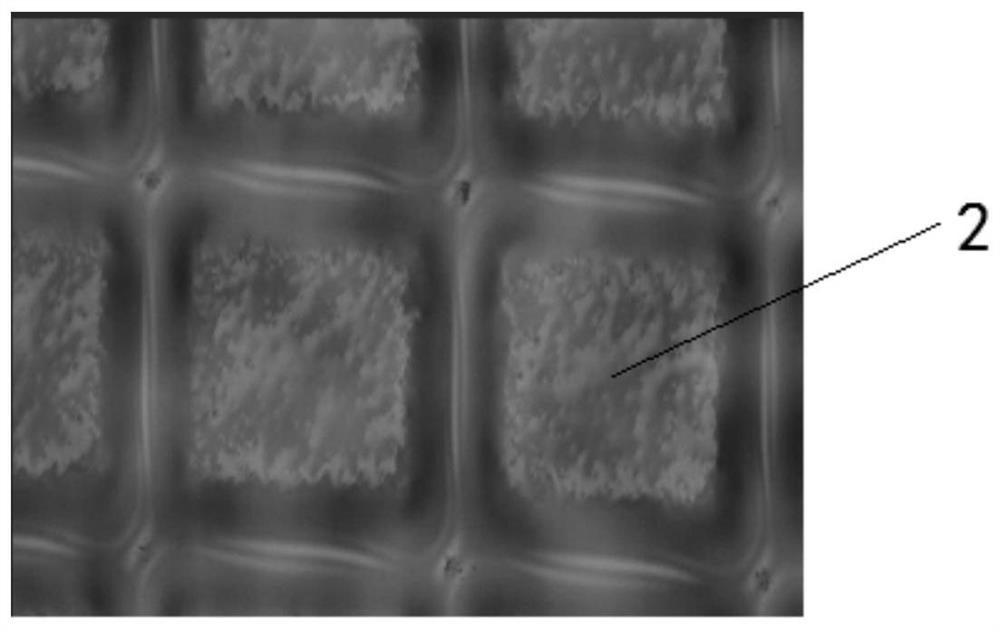

[0040]Such asfigure 2 As shown, the structural schematic view of the glass light guide plate of the present embodiment includes a glass substrate 1 and an upper surface of the glass substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com