Method, device and system for antegrade prediction of blast furnace condition

A prediction method and blast furnace technology, applied in the direction of prediction, manufacturing calculation system, data processing application, etc., can solve the problems of poor accuracy of blast furnace condition prediction and judgment, and achieve the effect of reasonable judgment standard and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

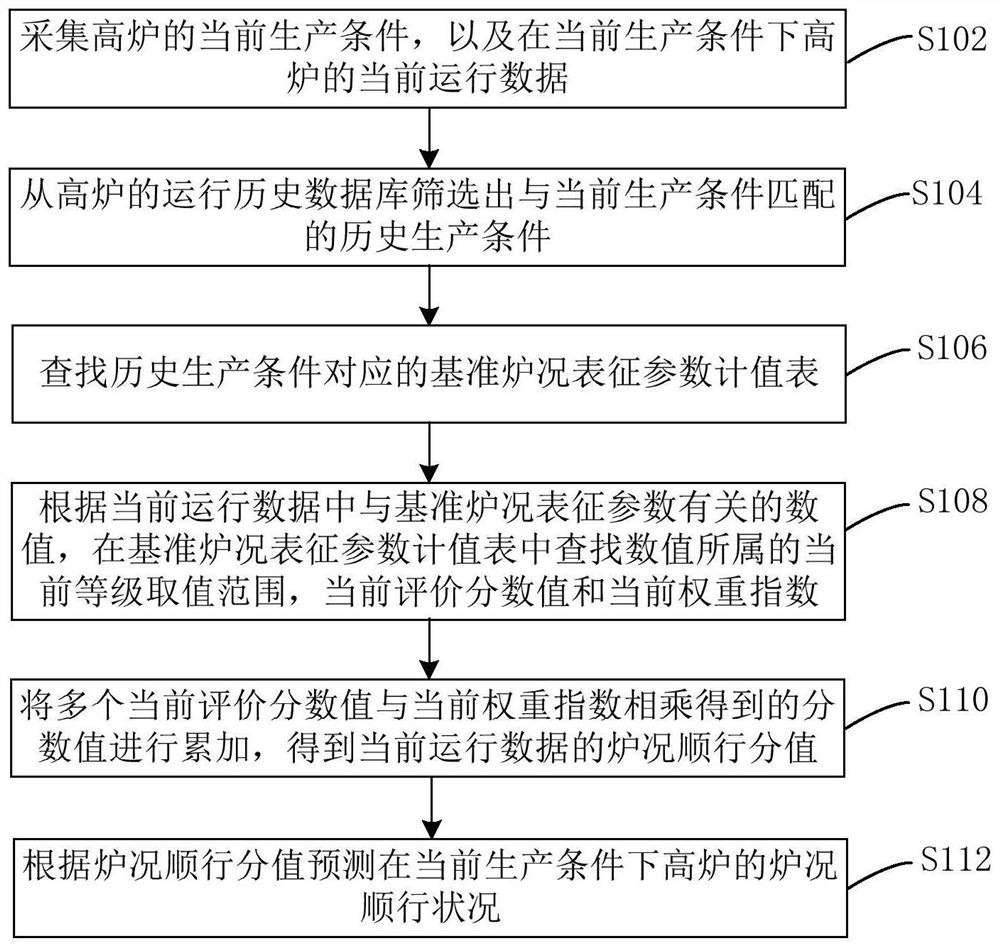

[0031] This embodiment provides a method for predicting the condition of a blast furnace antegradely, referring to figure 1 A flow chart of a blast furnace condition antegrade prediction method shown, the method includes the following steps:

[0032] Step S102, collecting the current production conditions of the blast furnace and the current operating data of the blast furnace under the current production conditions;

[0033] In actual implementation, the current production conditions can include the external environment of the blast furnace operation, production demand, raw material status, etc. The production demand is usually an artificially set production target, such as the iron content in the product, etc., when collecting the current production conditions of the blast furnace During the process, temperature detection devices, humidity detection devices, etc. can be used to collect external environmental conditions. The raw fuel status can be the composition category, co...

Embodiment 2

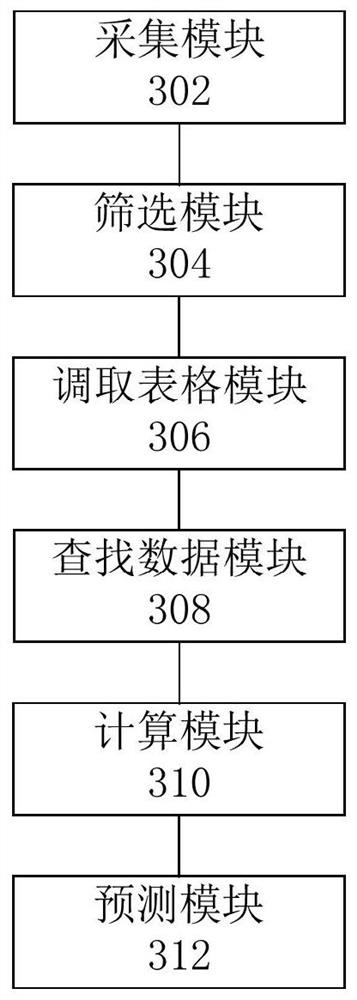

[0082] This embodiment also provides a blast furnace condition antegrade prediction device, refer to image 3 Shown is a structural schematic diagram of an antegrade prediction device for blast furnace conditions, which includes:

[0083] A collection module 302, configured to collect the current production conditions of the blast furnace and the current operating data of the blast furnace under the current production conditions;

[0084] The screening module 304 is used to filter out the historical production conditions matching the current production conditions from the operation history database of the blast furnace; wherein, the operation history database stores the corresponding historical operation data of the blast furnace under the historical production conditions;

[0085] The calling table module 306 is used to search for the reference furnace condition characteristic parameter value table corresponding to the historical production conditions; wherein, the reference ...

Embodiment 3

[0094] This embodiment also provides a blast furnace operation data processing system, refer to Figure 4 A schematic structural diagram of a blast furnace operation data processing system shown, the system includes a network switch 402, and a raw material yard system 404 connected to the network switch, an inspection system 406, a slag iron transportation system 408, a production management system 410, and a database server 412 , blast furnace control system 414 and application server 416;

[0095] The raw material yard system is used to collect the raw fuel quality parameters of the blast furnace; it mainly collects the raw fuel and its logistics supply data of the raw material yard;

[0096] The inspection system is used to inspect the molten iron and slag produced by the blast furnace, and generate inspection data; the inspection data is mainly the corresponding rapid inspection and laboratory data of molten iron and slag;

[0097] The iron and slag transportation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com