Granularly-separable ceramic substrate and separation method thereof

A ceramic substrate and separation method technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the strength of the ceramic substrate body, fragility, and high production costs of packaged products, so as to improve production efficiency and economy. Benefits, enhanced mechanical strength, and improved production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

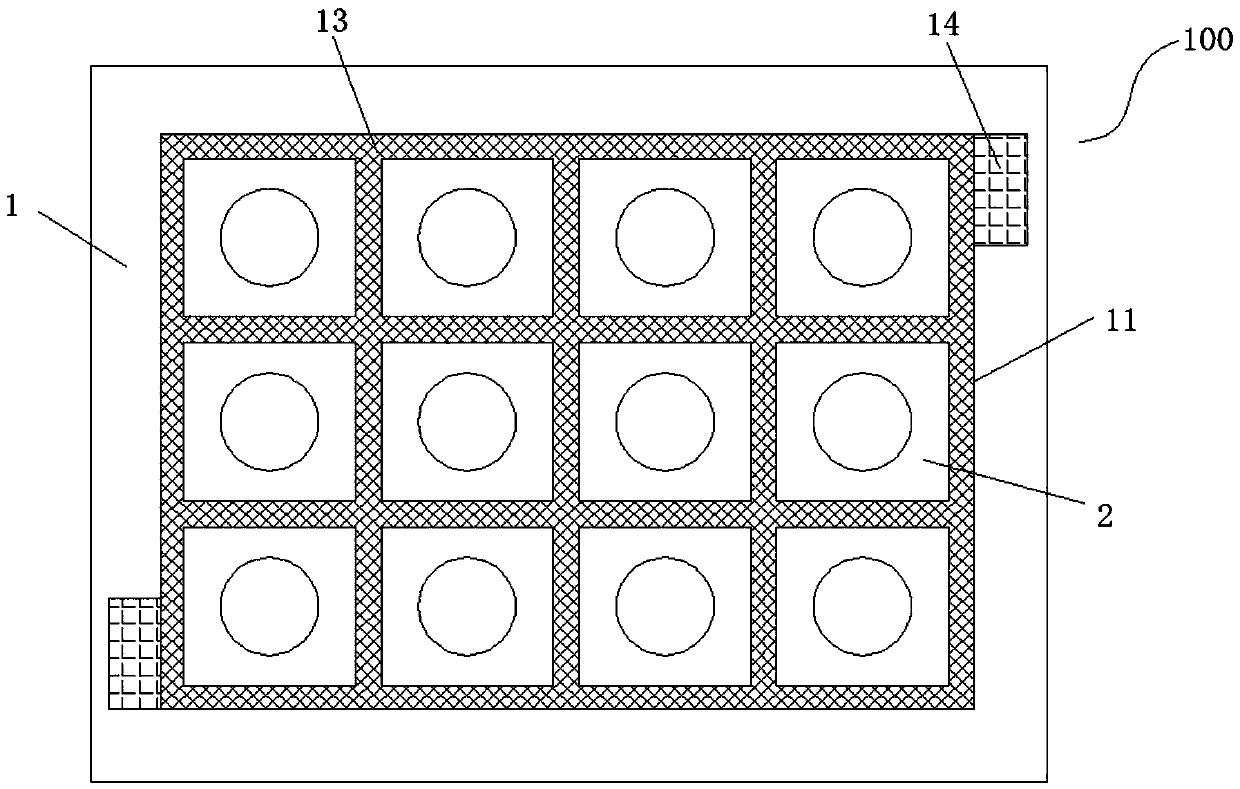

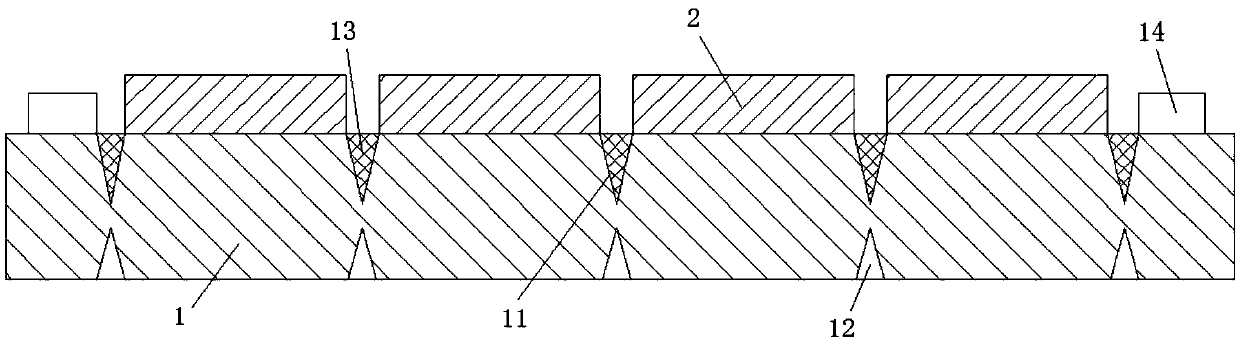

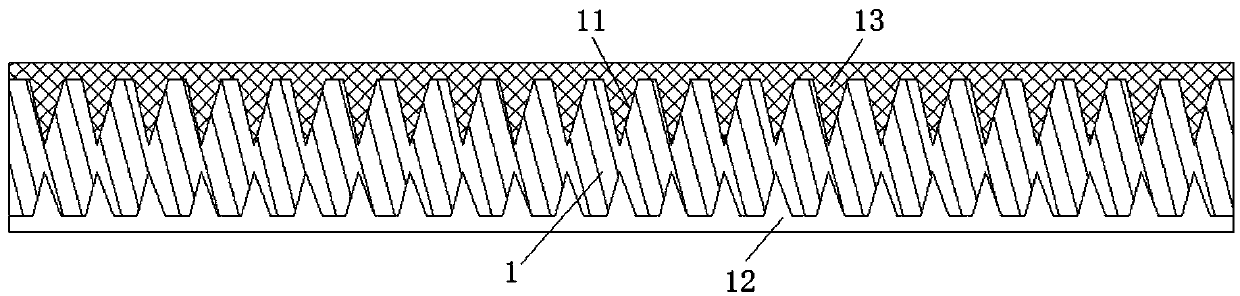

[0032] Such as Figure 1-3 As shown, the present embodiment provides a granular-separable ceramic substrate 100 , including a substrate body 1 and a circuit unit 2 disposed on the substrate body 1 .

[0033] The planar cross-sectional area of the substrate body 1 is rectangular, and the planar cross-sectional area of the circuit unit 2 arranged on the substrate body 1 is also rectangular, and arranged in an array on the upper end surface of the substrate body 1, In order to facilitate subsequent processing and production. The material of the substrate in this embodiment is a common ceramic material such as alumina, zirconia, aluminum nitride, etc., and the ceramic material contains conventional doping components. The circuit unit 2 can be provided with several according to the actual production situation, and each circuit unit 2 is provided with a printed circuit that can realize its own electrical function; It can still be used alone after separation.

[0034] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com