Handmade wine mud soap and preparation method thereof

A technology of wine sludge and handmade soap, which is applied in the direction of chemical instruments and methods, soap detergents and other compounding agents, skin care preparations, etc., to achieve mild and non-irritating skin, improve skin problems, prevent and treat skin problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

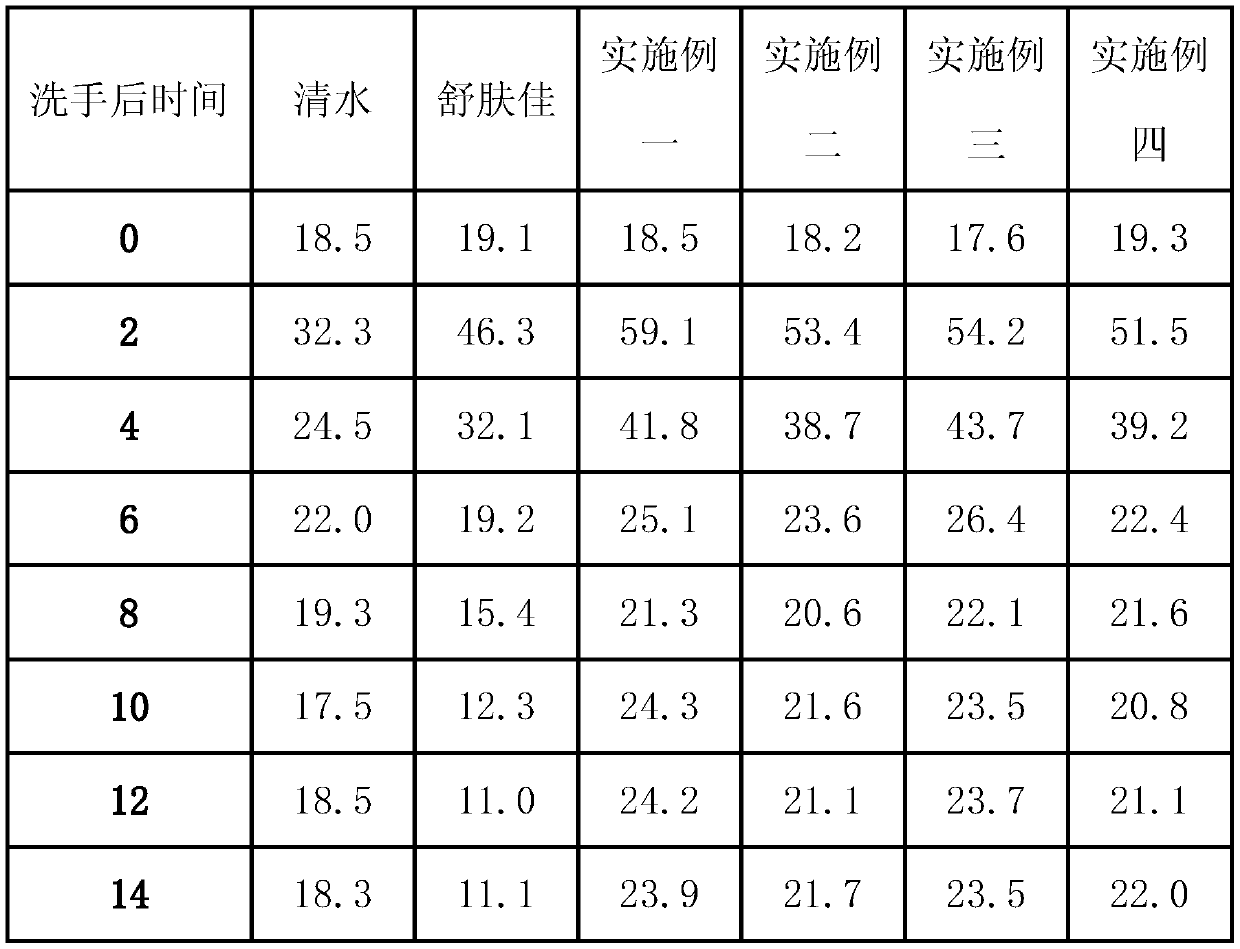

Examples

Embodiment 1

[0030] A kind of wine mud handmade soap comprises the following raw materials by weight: 333 parts of olive oil, 133 parts of coconut oil, 80 parts of shea butter, 60 parts of sweet almond oil, 65 parts of cocoa butter, 95 parts of sodium hydroxide, 140 parts of purified water , 150 parts of Cabernet Sauvignon wine lees, 10 parts of sodium lactate.

[0031] A preparation method of wine mud handmade soap:

[0032] Put the weighed coconut oil, shea butter, and cocoa butter in hot water at 70-80°C and heat them to a liquid state, then cool down to 45-50°C for later use.

[0033] Heat the weighed olive oil and sweet almond oil to 45-50° C., add melted coconut oil, shea butter, and cocoa butter to obtain part A, and keep the temperature for later use.

[0034] Add sodium hydroxide to purified water, stir evenly, cool down to 45°C, add sodium lactate, and stir evenly to obtain part B, keep the temperature for later use.

[0035] Heating the wine lees of Cabernet Sauvignon red wine...

Embodiment 2

[0042] A kind of wine mud handmade soap comprises the following raw materials by weight: 330 parts of olive oil, 130 parts of coconut oil, 80 parts of shea butter, 60 parts of sweet almond oil, 60 parts of cocoa butter, 92 parts of sodium hydroxide, and 140 parts of purified water , 140 parts of wine lees of rose-scented dry white wine, 5 parts of sodium lactate.

[0043] A preparation method of wine mud handmade soap:

[0044] Put the weighed coconut oil, shea butter, and cocoa butter in hot water at 70-80°C and heat them to a liquid state, then cool down to 45-50°C for later use.

[0045] Heat the weighed olive oil and sweet almond oil to 45-50° C., add melted coconut oil, shea butter, and cocoa butter to obtain part A, and keep the temperature for later use.

[0046] Add sodium hydroxide to purified water, stir evenly, cool down to 45°C, add sodium lactate, and stir evenly to obtain part B, keep the temperature for later use.

[0047] Heat the wine lees of Rosé-scented dr...

Embodiment 3

[0054] A kind of wine slime handmade soap comprises the following raw materials in parts by weight: 340 parts of olive oil, 135 parts of coconut oil, 90 parts of shea butter, 70 parts of sweet almond oil, 70 parts of cocoa butter, 95 parts of sodium hydroxide, and 145 parts of purified water , 150 parts of Cabernet Sauvignon wine lees, 10 parts of sodium lactate.

[0055] A preparation method of wine mud handmade soap:

[0056] Put the weighed coconut oil, shea butter, and cocoa butter in hot water at 70-80°C and heat them to a liquid state, then cool down to 45-50°C for later use.

[0057] Heat the weighed olive oil and sweet almond oil to 45-50° C., add melted coconut oil, shea butter, and cocoa butter to obtain part A, and keep the temperature for later use.

[0058] Add sodium hydroxide to purified water, stir evenly, cool down to 45°C, add sodium lactate, and stir evenly to obtain part B, keep the temperature for later use.

[0059] Heating the wine lees of Cabernet Sau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com