Petroleum solvent recovery equipment for drying machine

A petroleum solvent and recovery device technology, applied in the field of dryers, can solve the problems that petroleum solvents cannot be recycled, increase petroleum solvent consumption, and increase washing costs, so as to facilitate popularization and application, save washing costs, and reduce oil consumption. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

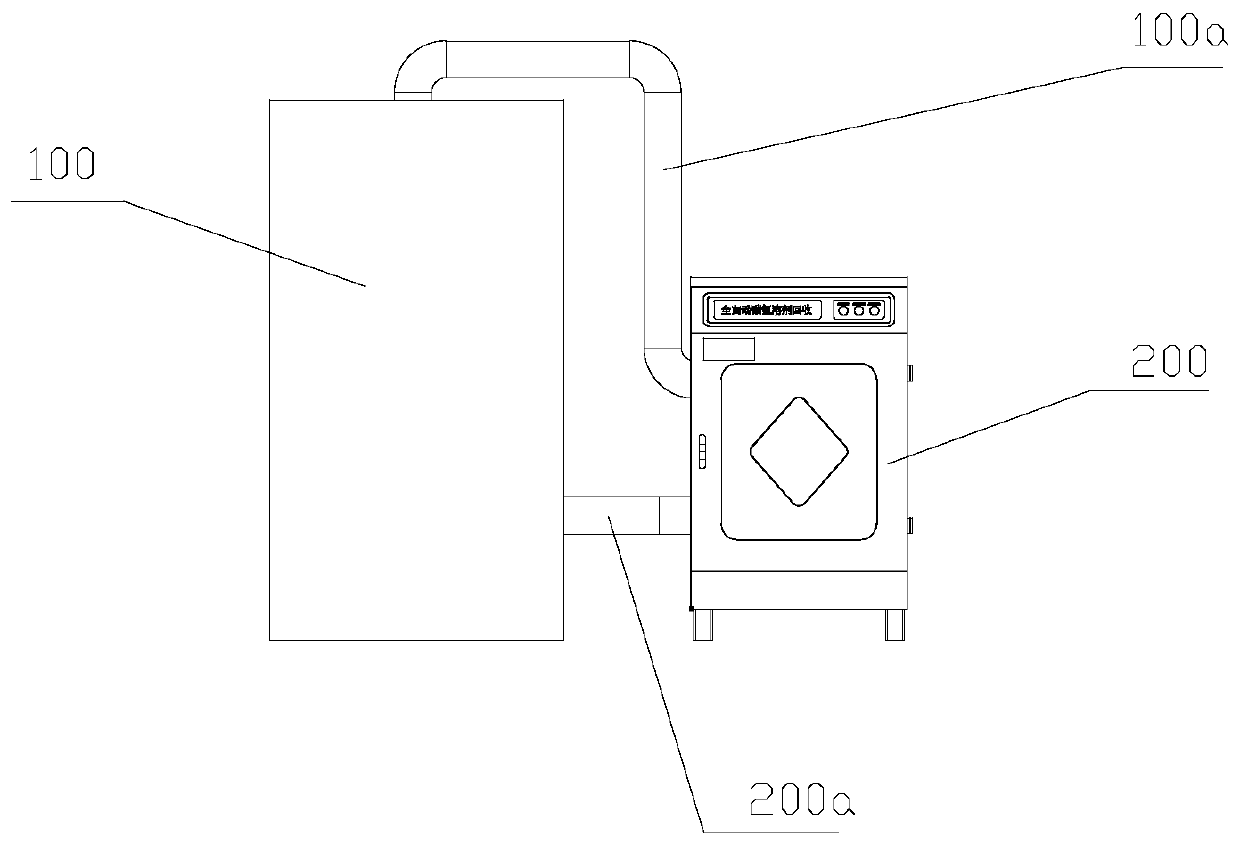

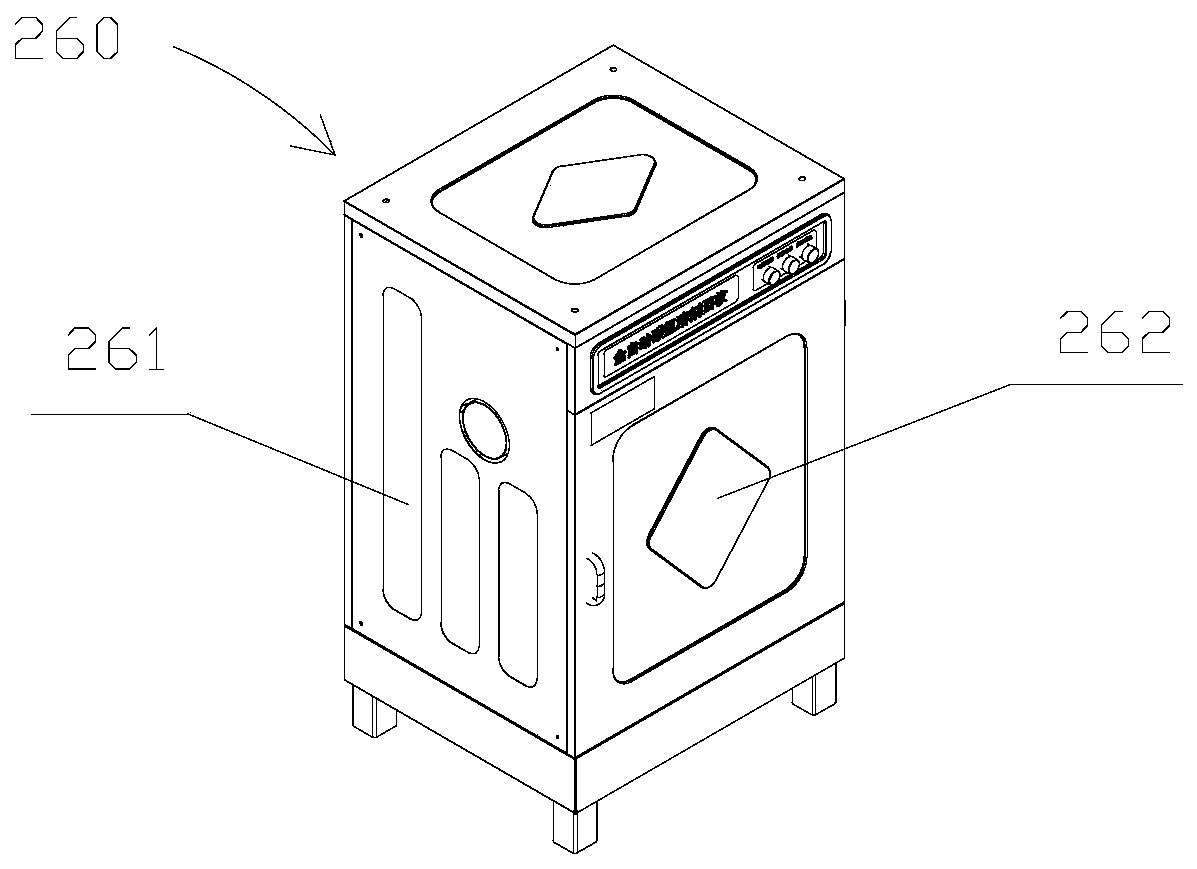

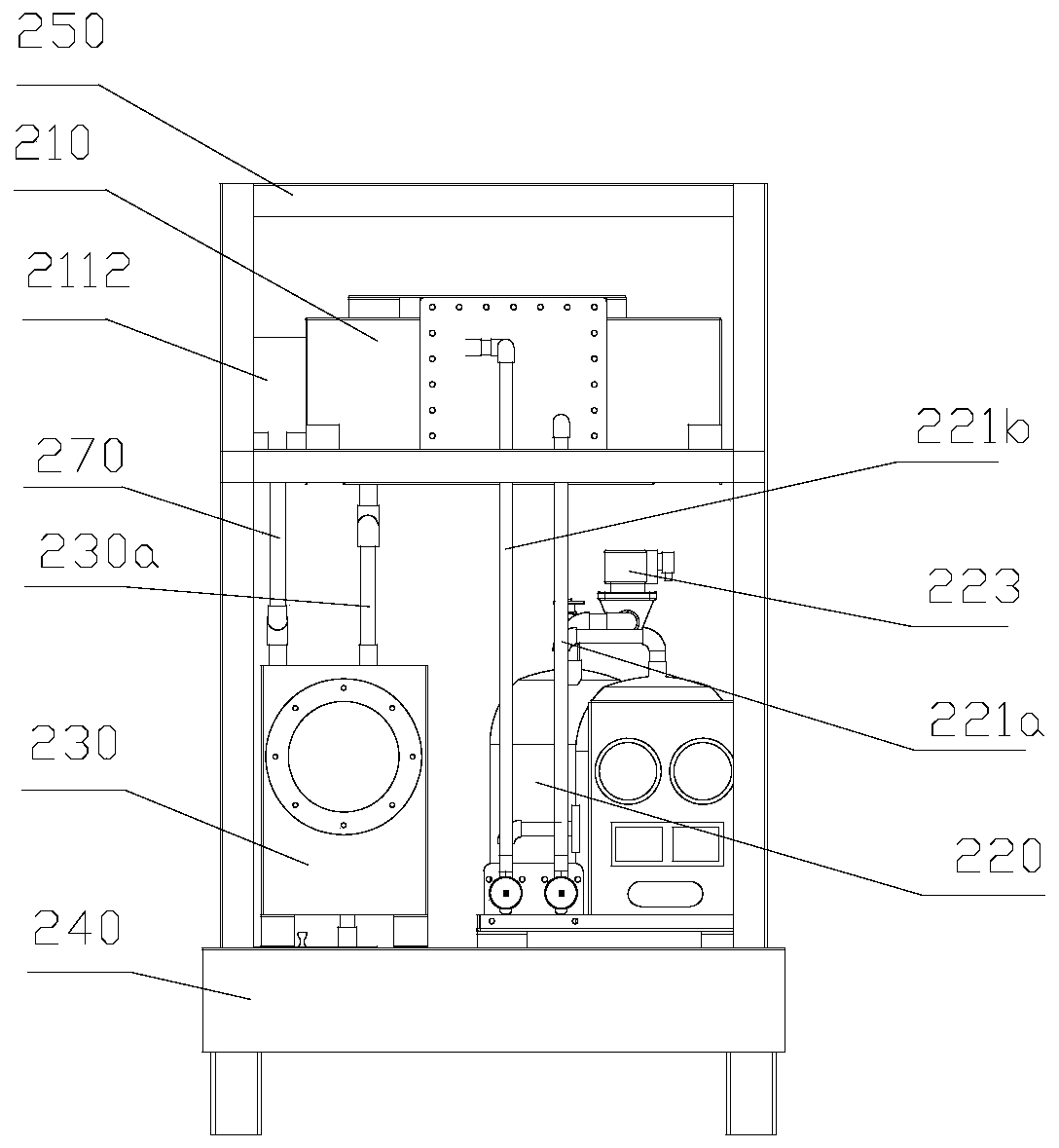

[0039] Such as figure 1 As shown, the petroleum solvent recovery device of the dryer includes a dryer 100 and a recovery mechanism 200, the dryer 100 has functions such as washing and drying, and the dryer 100 communicates with the recovery mechanism 200 through a channel 100a, and the drying The gas with petroleum solvent formed by the drying machine 100 during the drying process is sent to the recovery mechanism 200 through the channel 100a, and the recovery mechanism 200 recovers the petroleum solvent for use. In addition, the recovery mechanism 200 also communicates with the petroleum solvent through the channel 200a. The dryer 100 is connected to each other, and through the control valve, the recovered petroleum solvent can be sent to the dryer 100 through the channel 200a for recycling. It reduces the consumption of petroleum solvent in the dryer, saves the use cost, and at the same time greatly reduces the discharge of petroleum solvent in the dryer, largely avoiding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com