Wiring structure for piezoelectric hydrophone array

A wiring structure and hydrophone technology, applied in the direction of fluid using vibration, etc., can solve the problems of reducing the signal quality of hydrophones, crosstalk of similar wires, difficult assembly and maintenance, etc., to avoid mutual twisting contact, reduce crosstalk, and protect The effect of wire solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

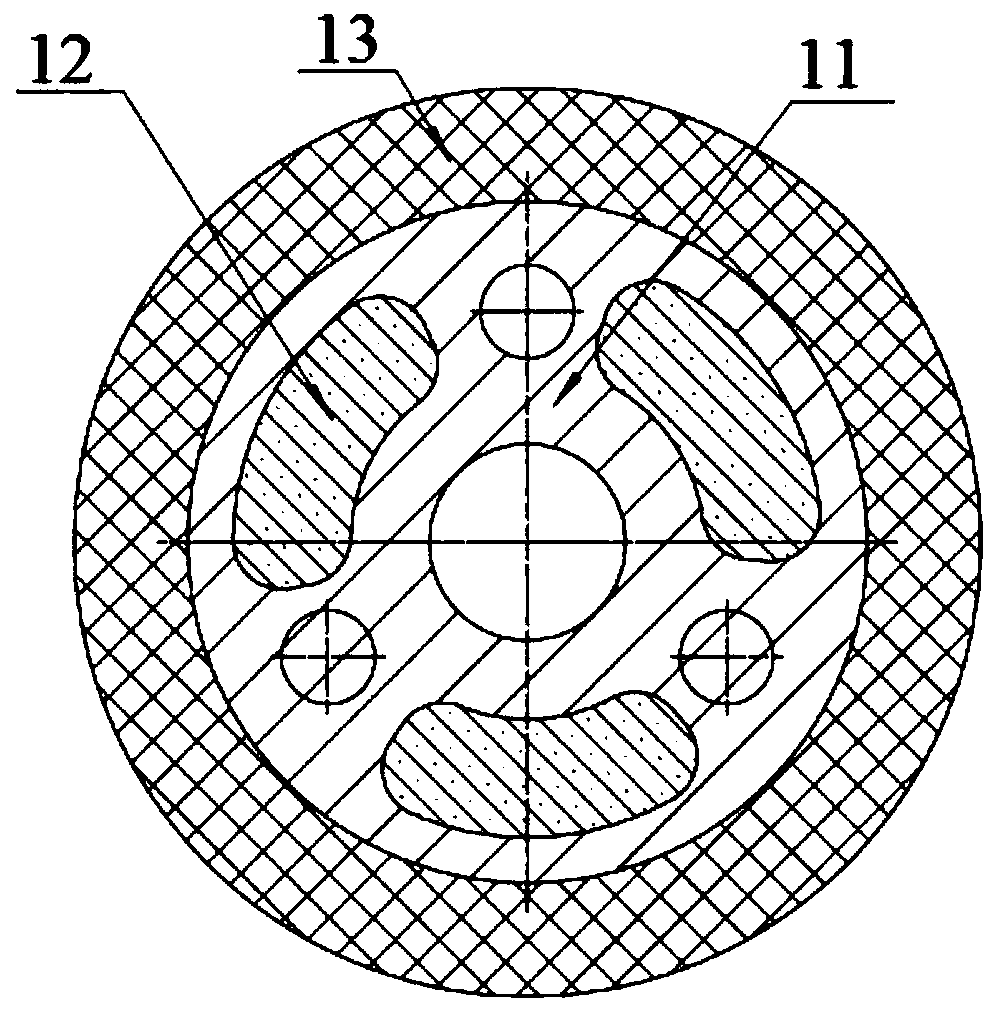

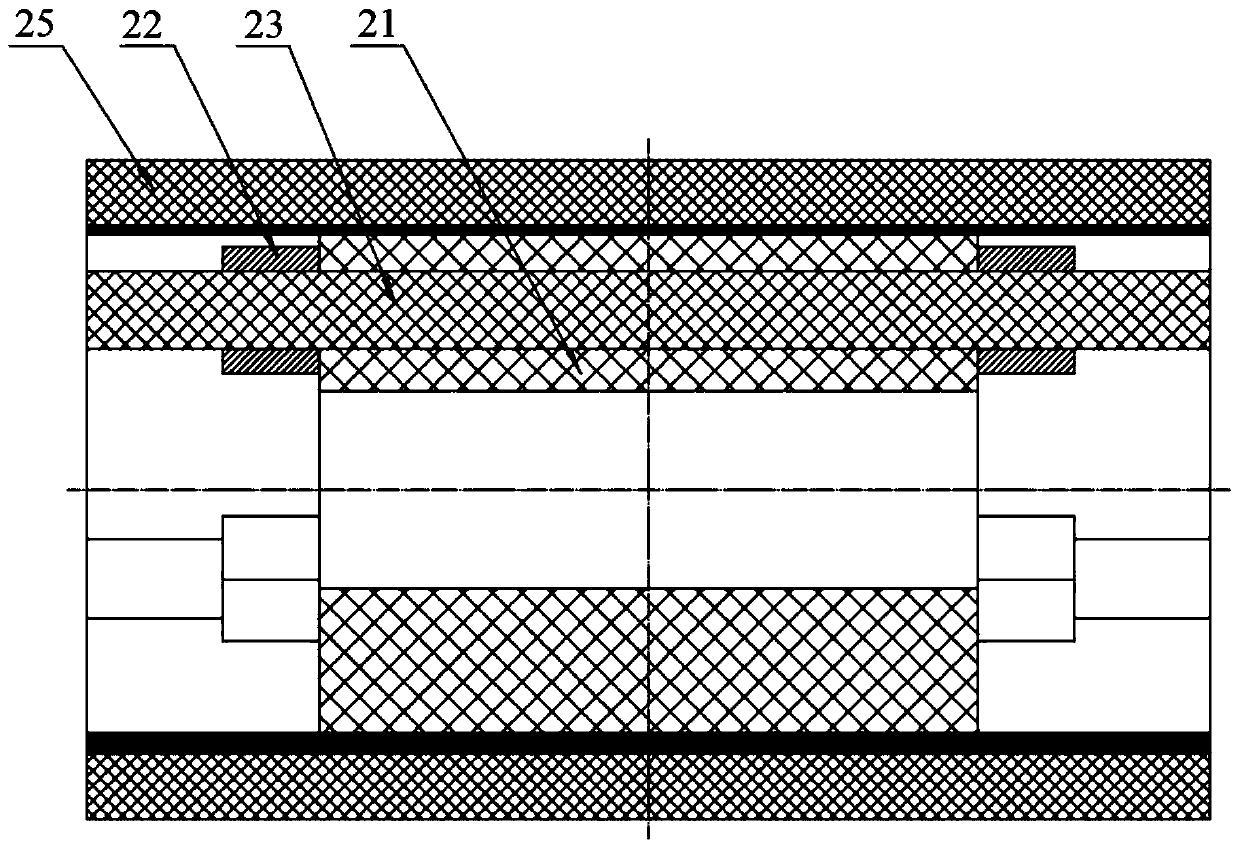

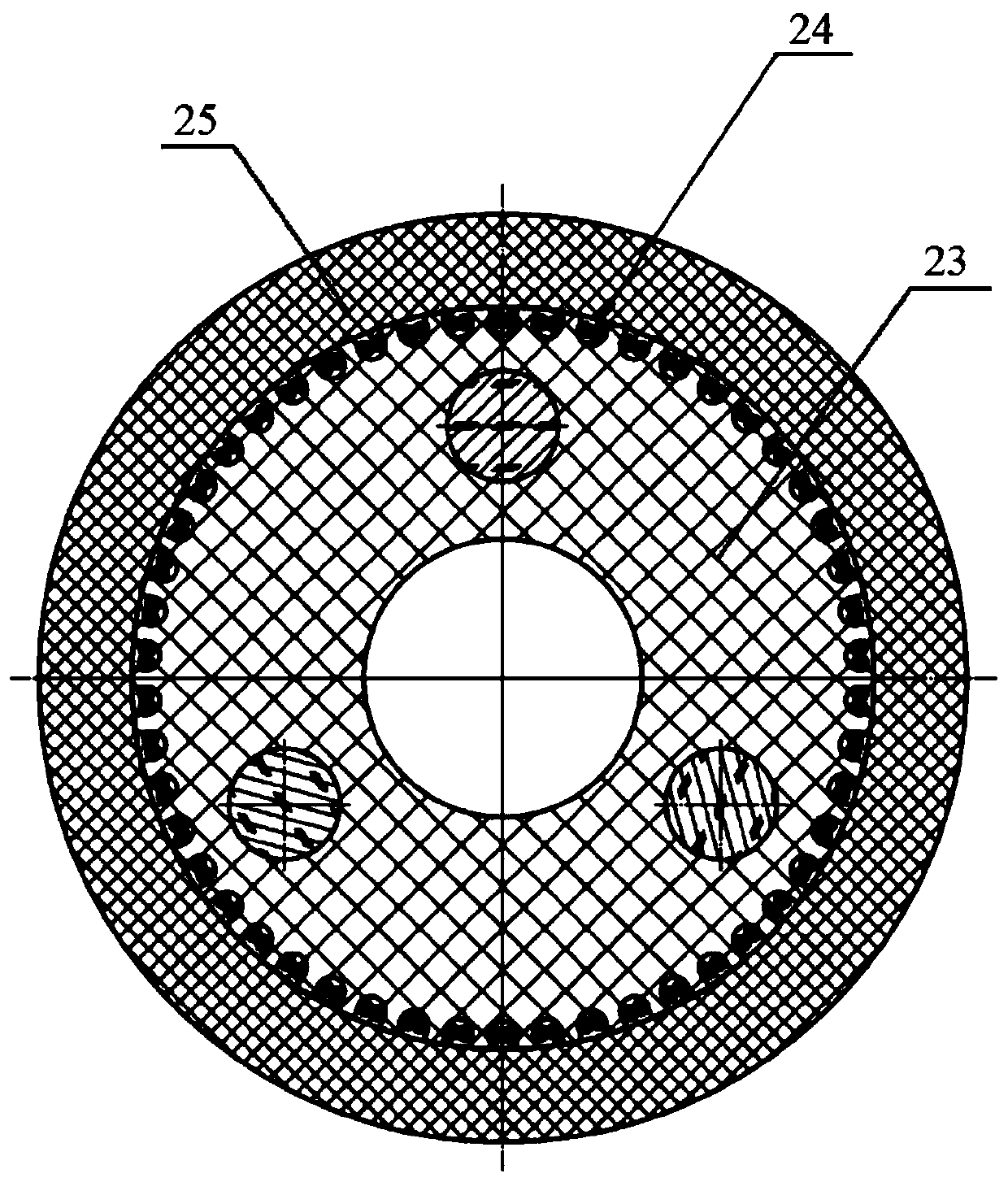

[0023] The invention provides a wiring structure of a piezoelectric hydrophone array, the section of which is as follows figure 2 shown. The wiring structure of the piezoelectric hydrophone array includes a support block 21 and a cold pressure ring 22; the cold pressure ring 22 fixes the support block 21 and the hydrophone together in the piezoelectric hydrophone array On the flexible load-bearing structure 23. Further, the support block 21 has a wire groove 24 in the circumferential direction, such as image 3 shown. After welding the lead wires of the hydrophone and the preset wires in the piezoelectric hydrophone array, the solder joints and the preset wires of a certain length are embedded in the wire groove 24 along the circumferential direction according to the wire sequence. Furthermore, the material of the flexible load-bearing structure 23 is a polyurethane material with a characteristic impedance similar to that of water, and the polyurethane material has a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com