Roller and preparation method of roller

A roll and molten iron technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of large differences in working layer structure, inoculation temperature, time influence, easy segregation, etc., and achieve the ability to maintain the accuracy of the roll surface Strong, eliminate tissue heredity, avoid tissue abnormal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

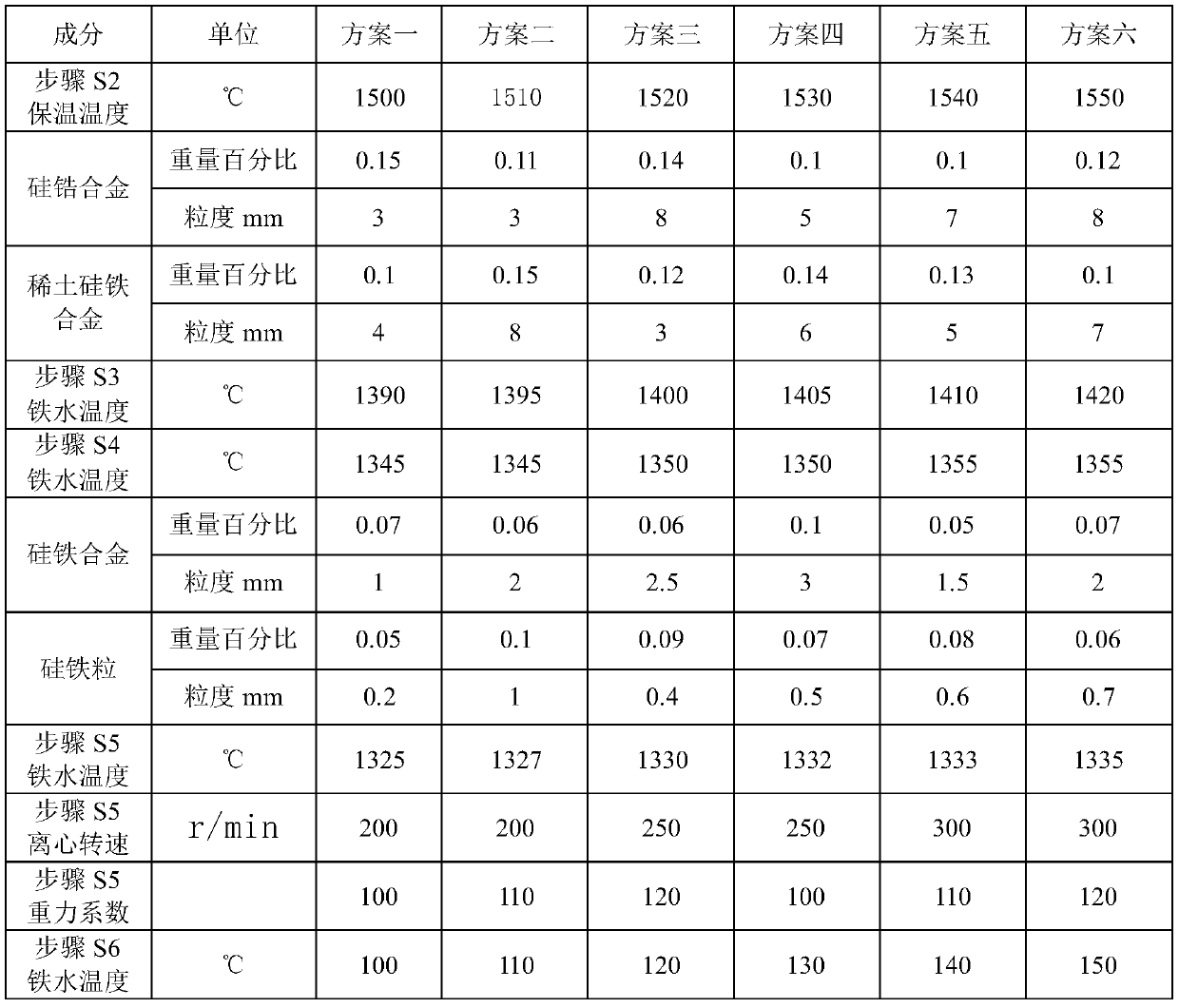

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0035] The present invention will be described in detail below in conjunction with examples.

[0036] The present embodiment relates to a kind of preparation method of roll, comprises the following steps:

[0037] S1. Use an intermediate frequency furnace to smelt the molten iron required for the outer layer of the roll. The melting temperature is 1300-1400°C. During the smelting process, adjust the composition of the molten iron so that the mass percentage of each element in the molten iron is:

[0038] C: 3.0%-3.5%, Si: 0.8%-1.5%, Mn: 0.8%-1.5%, Cr: 1.5%-2.5%, Ni: 4.0%-5.0%, Mo: 0.2%-1.0%, P< 0.05%, S<0.03%, balance Fe;

[0039] In this process, the smelting raw materials can use 40% high-nickel-chromium return material, 30% pig iron, 20% scrap steel and some alloys for batching, heating and dissolving, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com