Control method, system and device for electric arc additive manufacturing

A technology of additive manufacturing and control methods, applied in the field of additive manufacturing, can solve problems such as unsatisfactory, and achieve the effect of improving quality and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

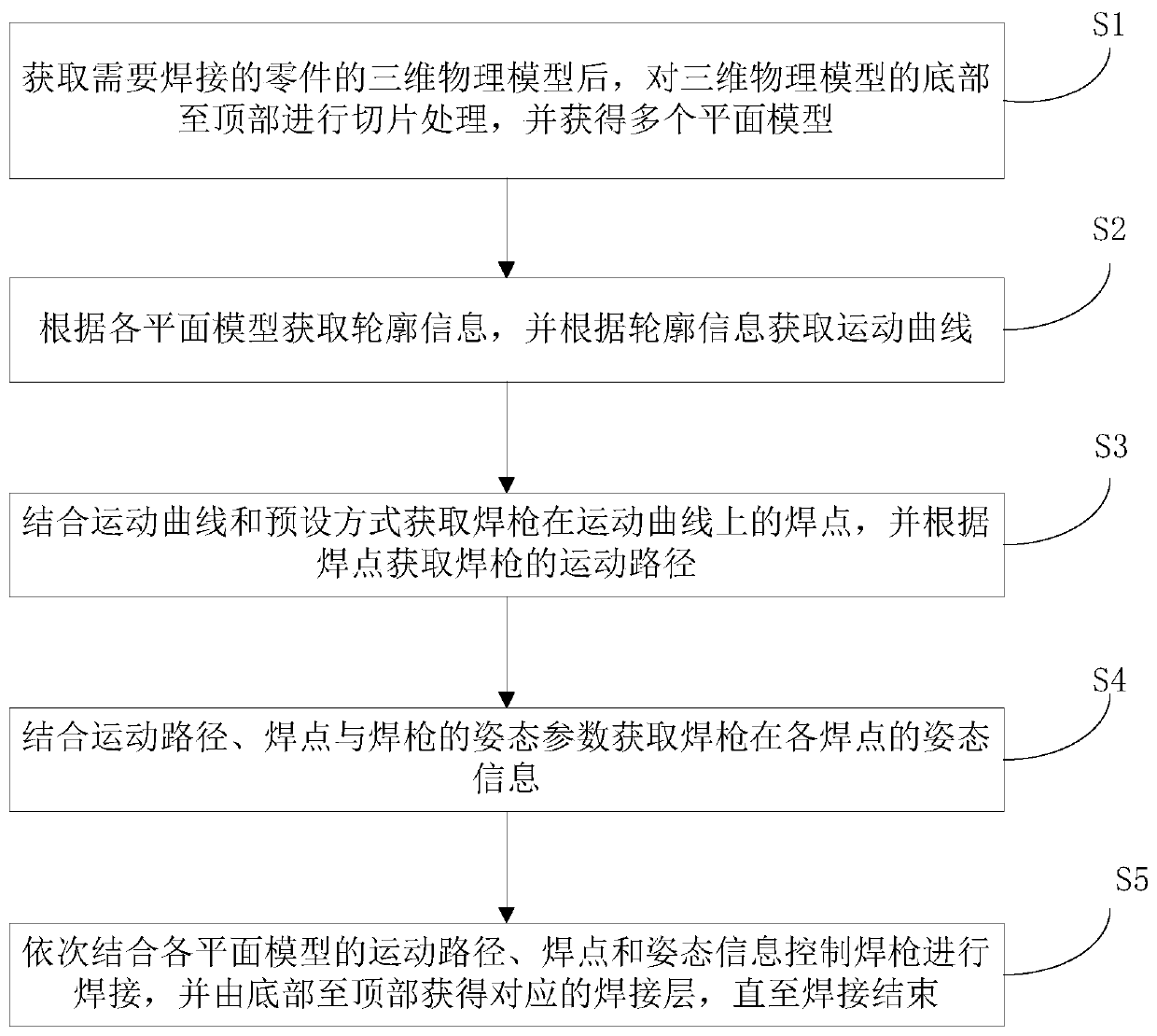

[0050] Such as figure 1 As shown, this embodiment provides a control method for arc additive manufacturing, including the following steps:

[0051] S1. After obtaining the three-dimensional physical model of the parts to be welded, slice the three-dimensional physical model from the bottom to the top, and obtain multiple plane models;

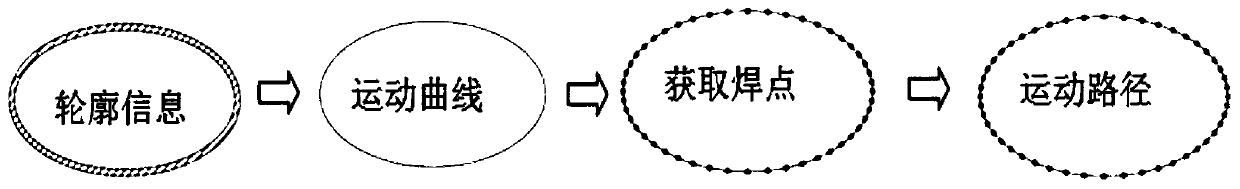

[0052] S2. Obtain contour information according to each planar model, and obtain a motion curve according to the contour information;

[0053] S3. Combining the motion curve and the preset method to obtain the soldering point of the welding torch on the motion curve, and obtain the motion path of the welding torch according to the soldering point;

[0054] S4. Obtain the posture information of the welding torch at each welding spot in combination with the motion path, the posture parameters of the welding spot and the welding torch;

[0055] S5. Control the welding torch to perform welding by sequentially combining the movement paths, welding...

Embodiment 2

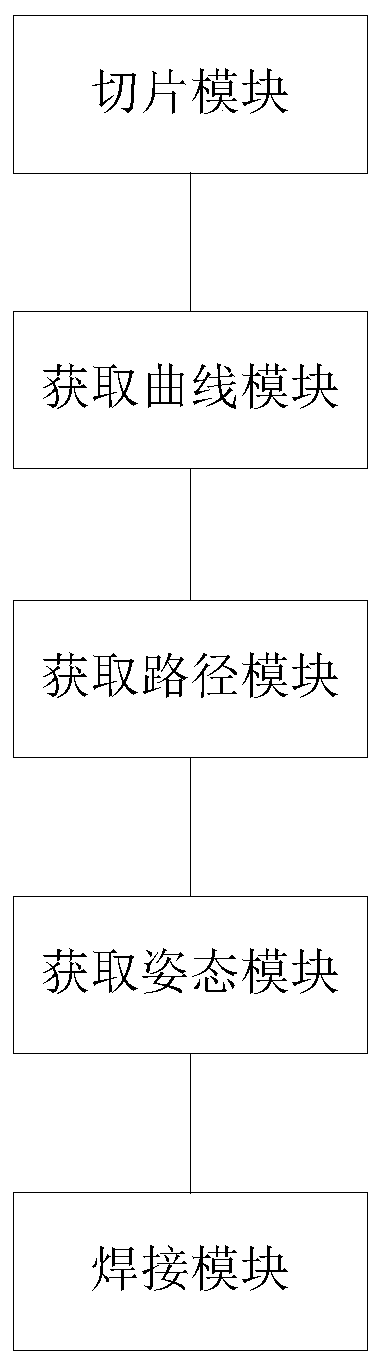

[0078] Such as figure 2 As shown, this embodiment provides a control system for arc additive manufacturing, including:

[0079] The slicing module is used to slice the bottom to top of the three-dimensional physical model after obtaining the three-dimensional physical model of the parts to be welded, and obtain multiple plane models;

[0080] Obtaining a curve module, configured to obtain contour information according to each plane model, and obtain a motion curve according to the contour information;

[0081] The acquisition path module is used to obtain the welding point of the welding torch on the movement curve in combination with the movement curve and the preset method, and obtain the movement path of the welding torch according to the welding point;

[0082] The attitude acquisition module is used to obtain the attitude information of the welding torch at each welding spot in combination with the attitude parameters of the motion path, the welding spot and the welding...

Embodiment 3

[0091] This embodiment provides a control device for arc additive manufacturing, including:

[0092] at least one processor;

[0093] at least one memory for storing at least one program;

[0094] When the at least one program is executed by the at least one processor, the at least one processor implements the arc additive manufacturing control method described in the first embodiment.

[0095] A control device for arc additive manufacturing in this embodiment can execute a control method for arc additive manufacturing provided in Embodiment 1 of the method of the present invention, can execute any combination of implementation steps in the method embodiments, and has corresponding functions and beneficial effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com