Method for operating a hybrid vehicle

A hybrid vehicle and transmission technology, which is applied in the arrangement of multiple different prime movers of hybrid vehicles and general power units, and the use of engine-driven traction, etc., can solve the problem of heavy energy storage devices, not too large, expensive, etc. problem, to achieve the effect of simple safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

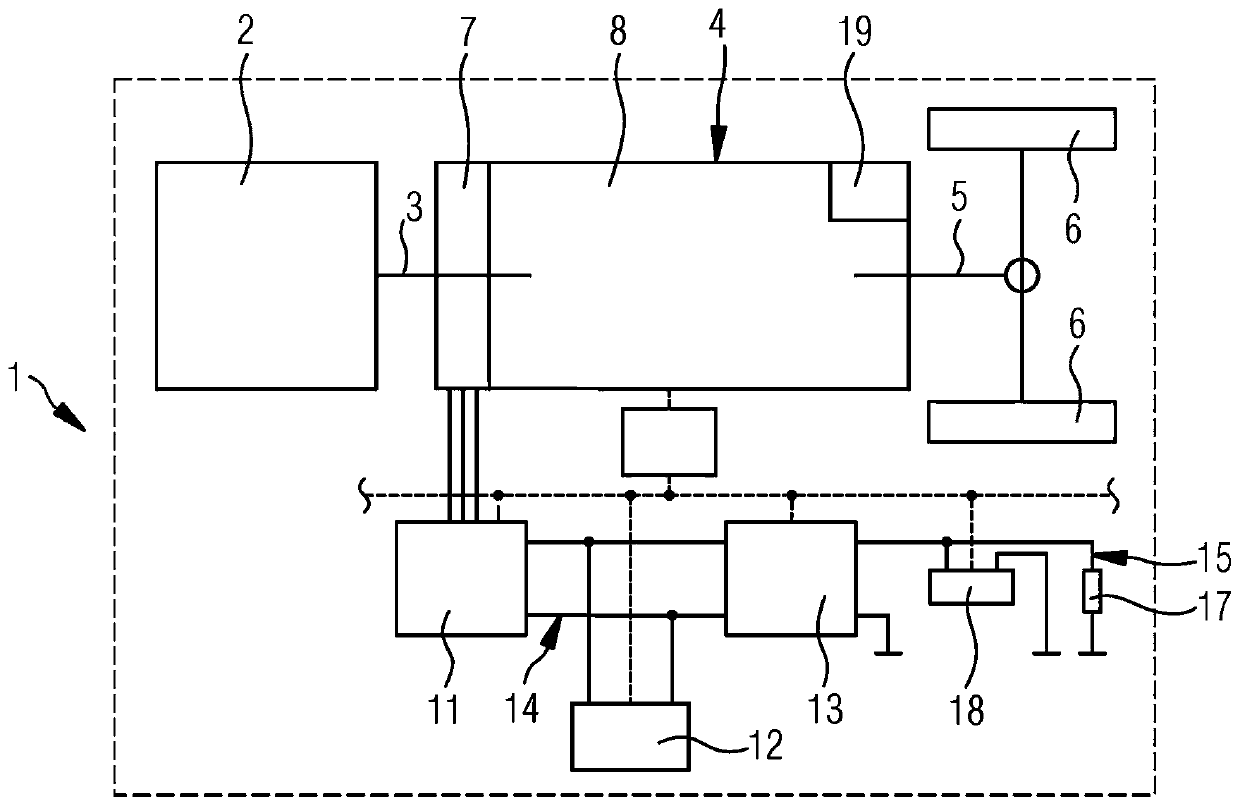

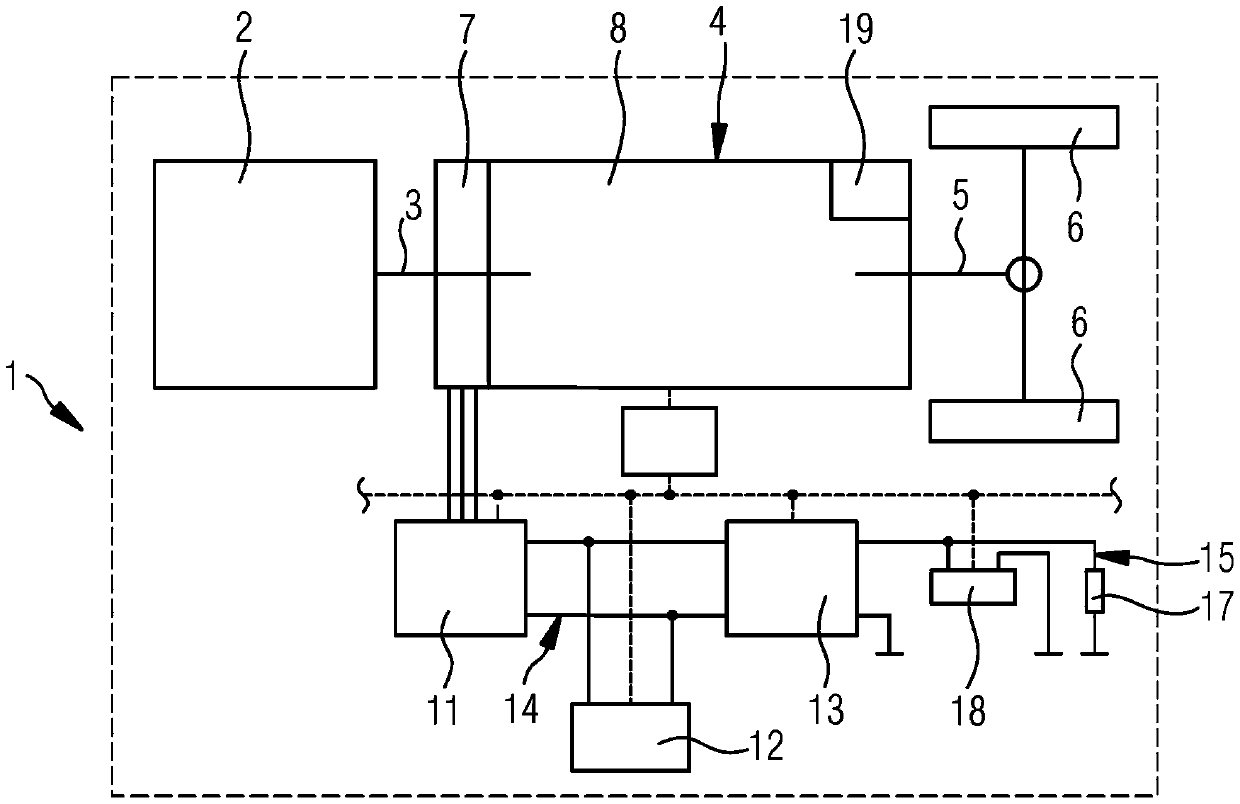

[0025] exist figure 1 A hybrid vehicle 1 is schematically indicated in the illustration of . It is driven by an internal combustion engine 2, for example a diesel engine or a gasoline engine. Via an input shaft 3 , the internal combustion engine is connected to a transmission system 4 , which contains and controls all functions of the hybrid drive apart from the internal combustion engine 2 . The transmission system 4 is connected via an output shaft 5 to two designated driven wheels 6 . Part of the transmission system 4 is here an electric machine 7 and a transmission 8 , for example an automatic transmission with a differential converter. The transmission 8 can have a hydraulic retarder T as a wear-free permanent brake 9 . Another part of the transmission system 4 is the electrical control. For this purpose there is a transmission control unit 9 which is connected via a bus system 10 , preferably a CAN bus, to a vehicle control unit (not shown here). Another part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com