Environmentally-friendly water treatment device for tinned plate cleaning

An environmental protection device and water treatment technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of pollution, metal tin cannot be effectively recycled to the environment, etc., to reduce waste of resources , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

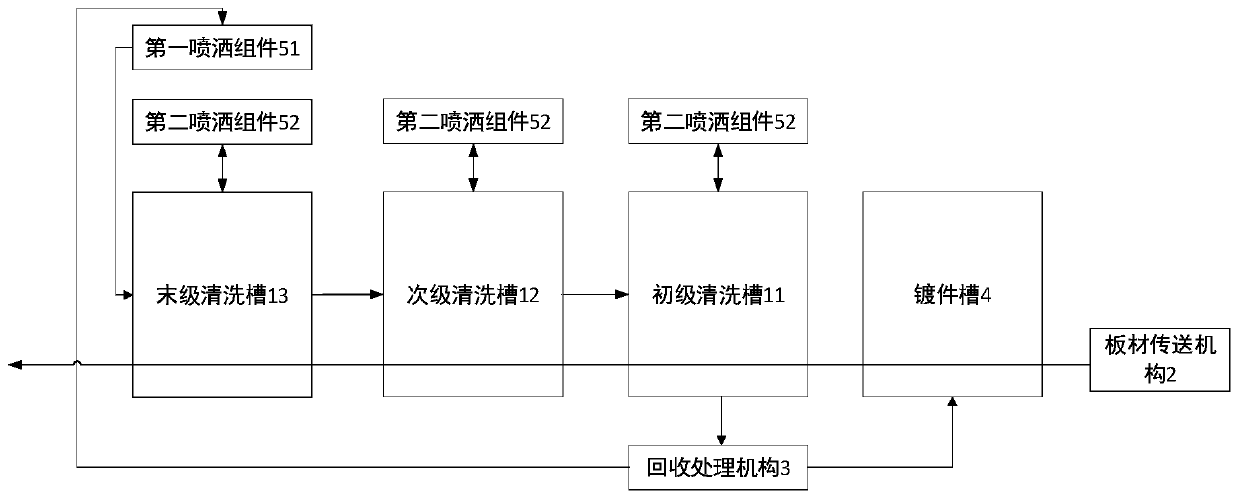

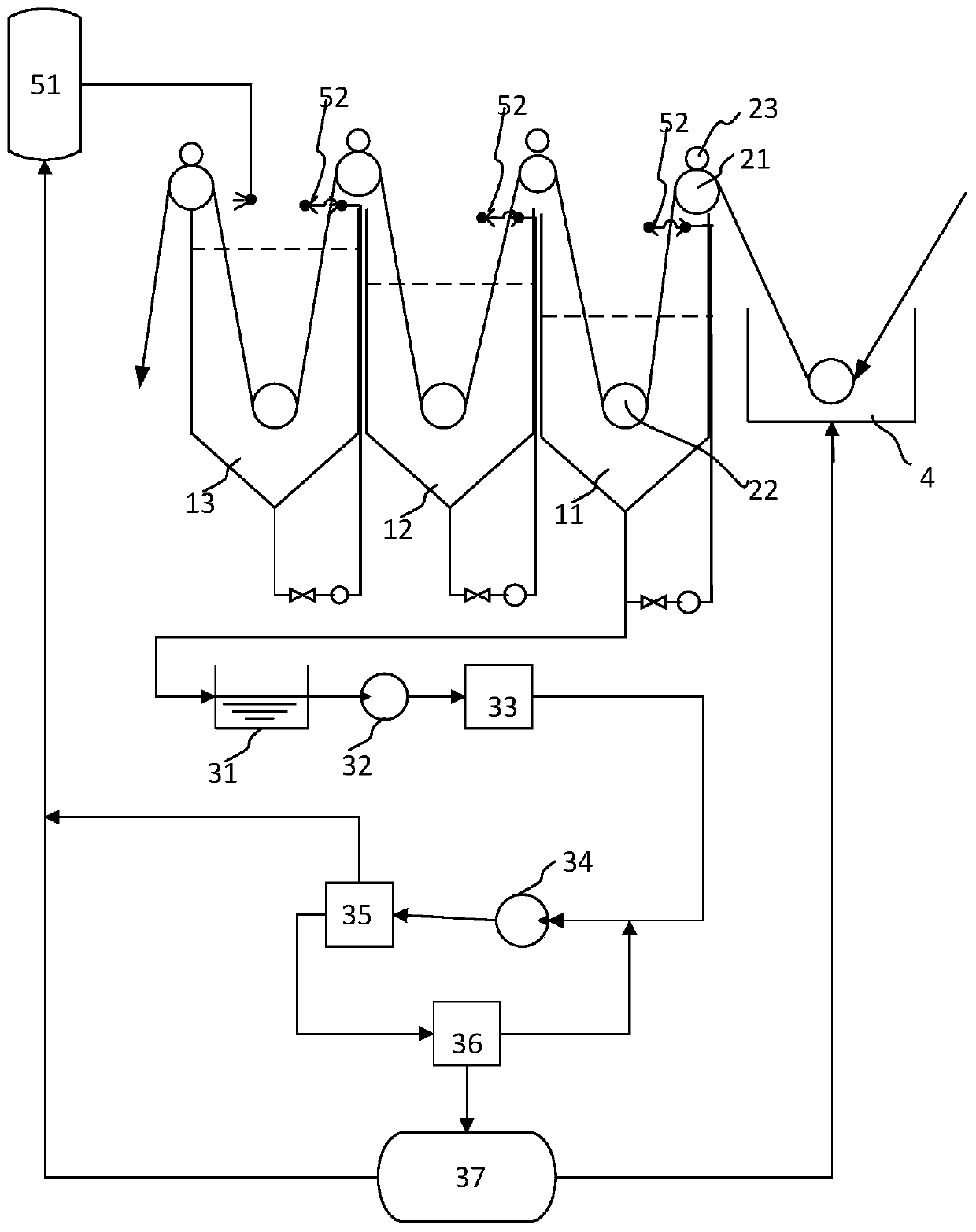

[0051] This embodiment provides a water treatment environmental protection device for cleaning tinplate, such as figure 1 and figure 2 As shown, it includes: a cleaning cycle mechanism, a plate conveying mechanism 2, a recovery processing mechanism 3 and a spraying mechanism.

[0052] Among them, the cleaning cycle mechanism includes a primary cleaning tank 11, a secondary cleaning tank 12 and a final cleaning tank 13. Cleaning water circulates in any one of the cleaning tanks to clean the surface of the board; the board conveying mechanism 2 drives the board to rotate through the primary The cleaning tank 11, the secondary cleaning tank 12, and the final cleaning tank 13 are output along the outlet side of the final cleaning tank 13; one end of the recycling mechanism 3 is connected to the cleaning water in the primary cleaning tank 11, and one end is connected to the plating tank 4. Form a recovery closed system; the recovery processing mechanism 3 includes a first-stage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com