A method for preparing unfired masonry from fresh electrolytic manganese slag

A technology for electrolytic manganese slag and masonry, which is applied in the fields of chemical industry, environmental protection, metallurgy, and building materials, can solve the problems of unreported industrialized technology, large differences in the physical and chemical properties of electrolytic manganese slag, and small amount of electrolytic manganese slag, and achieves The effect of promoting healthy development, low cost and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

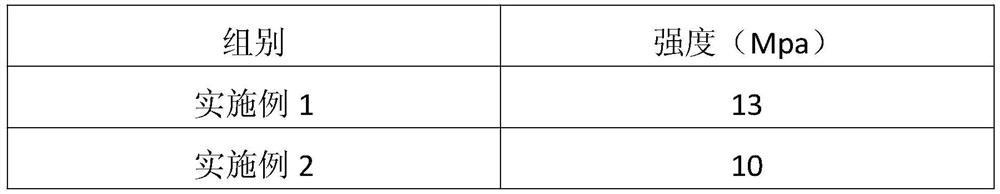

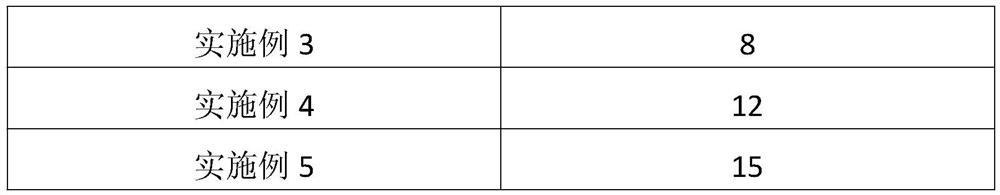

Embodiment 1

[0030] Example 1. A method for preparing unfired masonry from fresh electrolytic manganese slag, which is prepared according to the following steps;

[0031] a, take 500kg electrolytic manganese slag, use clean water to wash electrolytic manganese slag 3 times, get A product;

[0032] b. According to the weight of product A, add 1 part of product A to 3 parts of pretreatment liquid in parts by weight, the temperature of pretreatment is 20°C, and the time of pretreatment is 3 hours, then filter to obtain product B; The treatment solution contains sodium oxide, and the pH value of the pretreatment solution is 8;

[0033] c. According to the weight of product B, add 10% cement, 0.3% conditioner, 0.05% reinforcing agent and 25% water to product B by mass fraction, stir and mix to obtain product C; wherein the conditioner is red mud, Enhancer is diethylene glycol;

[0034] d. The product C is pressed into shape under a pressure of 5Mpa, sprayed with water and maintained for 25 d...

Embodiment 2

[0035] Example 2. A method for preparing unfired masonry from fresh electrolytic manganese slag, which is prepared according to the following steps;

[0036] a, get 500kg electrolytic manganese slag, use clear water to wash electrolytic manganese slag 4 times, get A product;

[0037] b. According to the weight of product A, in parts by weight, add 1 part of product A to 4 parts of pretreatment liquid, the temperature of pretreatment is 30 ℃, and the time of pretreatment is 15 hours, then filter to obtain product B; The treatment solution contains sodium oxide and magnesium oxide, and the pH value of the pretreatment solution is 9;

[0038] c. According to the weight of product B, by mass fraction, add 15% cement, 3% conditioner, 3% phosphogypsum, 0.1% reinforcing agent and 26% water to product B, stir and mix to obtain product C; The agent is red mud, and the enhancer is diethylene glycol;

[0039] d. Product C is pressed into shape under a pressure of 6Mpa, sprayed with wa...

Embodiment 3

[0040] Example 3. A method for preparing unfired masonry from fresh electrolytic manganese slag, which is prepared according to the following steps;

[0041] a, take 500kg electrolytic manganese slag, use clear water to wash electrolytic manganese slag 5 times, get A product;

[0042] b. According to the weight of product A, in parts by weight, add 1 part of product A to 5 parts of pretreatment liquid, the temperature of pretreatment is 45 ℃, and the time of pretreatment is 30 hours, then filter to obtain product B; The treatment solution contains sodium oxide, magnesium oxide and calcium oxide, and the pH value of the pretreatment solution is 10;

[0043] c. According to the weight of product B, add 20% cement, 6% conditioning agent, 7% phosphogypsum, 0.2% reinforcing agent and 27% water to product B, stir and mix to obtain product C; The agent is red mud, and the enhancer is diethylene glycol;

[0044] d. Product C is pressed into shape under a pressure of 7Mpa, sprayed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com