Preparation method of organotin catalyst, organotin catalyst and application thereof

A catalyst and organotin technology, applied in the field of organic synthesis, can solve problems such as weak catalytic activity, corrosion, and easy crystallization, and achieve the effects of wide application range, simple production process, and low crystallization point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

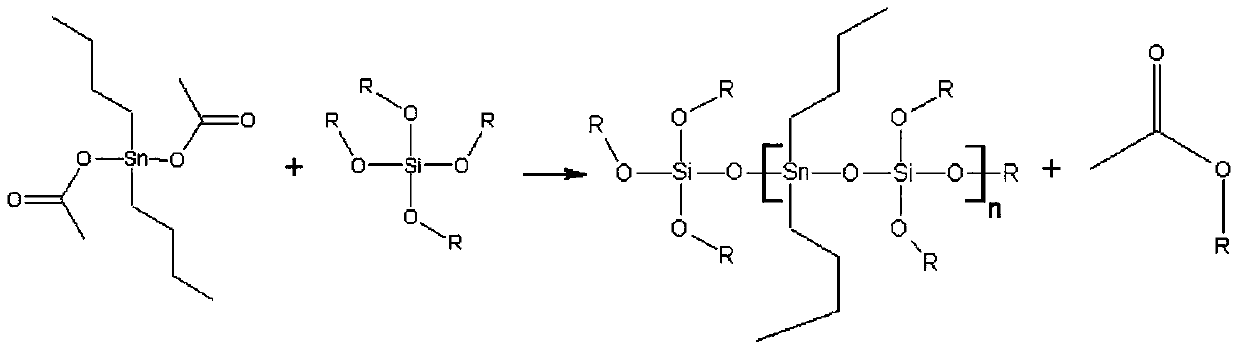

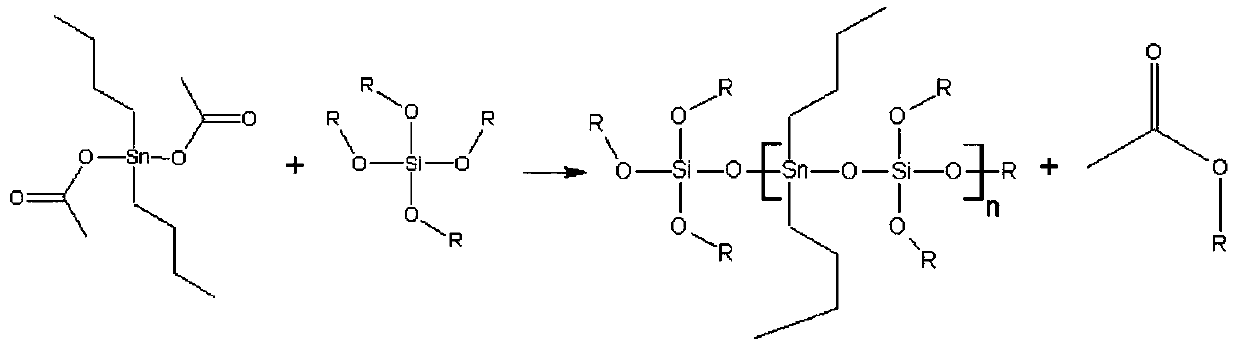

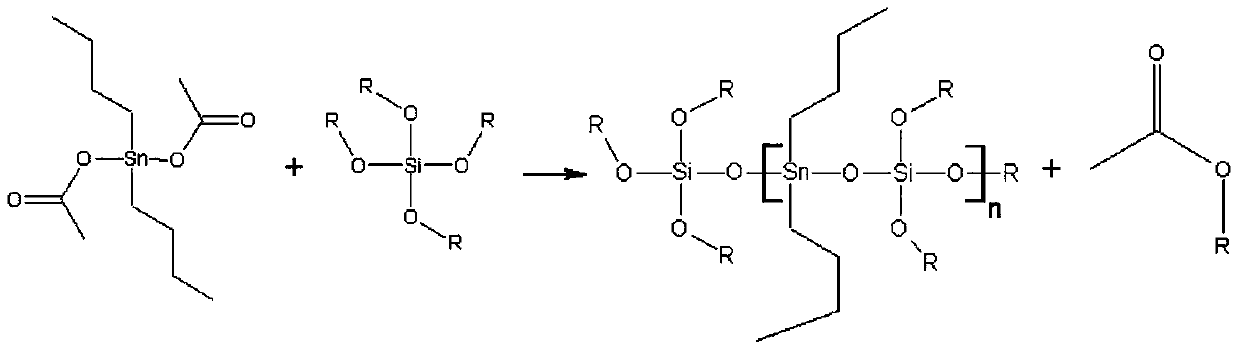

[0028] The embodiment of the present invention provides a method for preparing an organotin catalyst, comprising the following steps:

[0029] S1: Under the protection of nitrogen or inert gas, add dibutyltin diacetate and tetraalkoxysilane to the reaction kettle, the molar ratio of dibutyltin diacetate and tetraalkoxysilane is 1:1.5~2;

[0030] S2: Under stirring and heating conditions, carry out reflux reaction;

[0031] S3: Filtration, the obtained clear and transparent liquid is the organotin catalyst.

[0032] Compared with traditional organotin catalysts, the catalytic activity of the organotin catalysts prepared in the examples of the present invention is higher than that of dibutyltin dilaurate, which can meet the requirements of customers for preparing organosilicon room temperature vulcanized silicone rubbers with different curing speeds; Compared with butyl tin, it has no irritating odor, and the product has no irritating and corrosive small molecular substances du...

Embodiment 1

[0048] Reflux reaction: 175.5g of dibutyltin diacetate and 152g of tetramethoxysilane are added in a 500ml four-necked flask with reflux condenser, stirrer, thermometer and nitrogen protection, and the molar ratio is dibutyltin diacetate:tetramethoxysilane= 1:2. Then control the temperature of the heating mantle to raise the temperature of the material at 200° C., and control the stirring speed at 150 r / min. As the reaction continues, reflux is gradually generated, and the maximum material reflux temperature reaches 115°C. As the reflux rate increases, the material reflux temperature gradually decreases and finally stabilizes at 90-95°C, and the reaction is continued for 4 hours.

[0049] Distillation operation: change the reflux device to a collection device, and start to collect by-product ester small molecule substances. With the gradual separation of by-products, the temperature of the material rises gradually, and when the temperature of the material reaches 100°C, stop...

Embodiment 2

[0052] The operation steps of this embodiment are basically the same as those of Example 1, the difference is as follows: no distillation operation is carried out. Finally, 327.3 g of the light yellow, transparent liquid target product without mechanical impurities is obtained, and the tin content is 17.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com