Controllable self-crimping polyurethane film as well as preparation and application thereof

A polyurethane film and self-curling technology, applied in the field of smart materials, can solve the problems of increased risk, no self-curling performance, loss, etc., and achieve the effects of avoiding peeling, wide applicability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

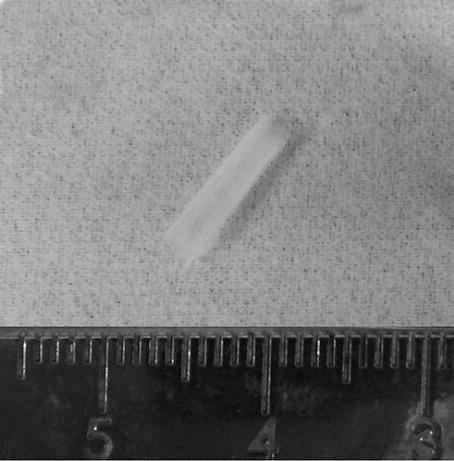

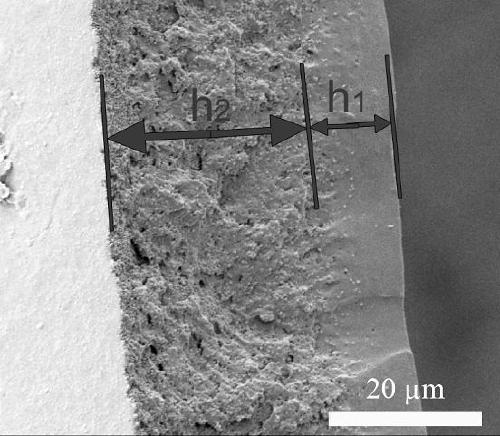

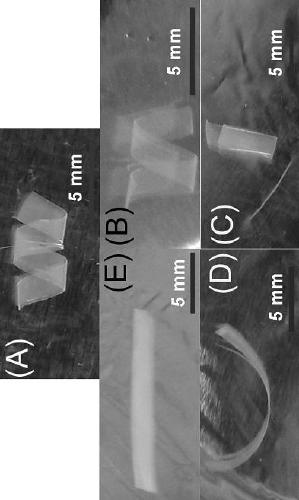

[0027] Example 1 A controllable self-curling polyurethane film, which is composed of a polyurethane layer and a polyurethane-silica nanosphere composite layer, with a thickness of 30 μm. The polyurethane-silica nanosphere composite layer accounts for 50% of the total thickness of the membrane material.

[0028] Its preparation method refers to: dissolving 10 parts by weight of solid polyurethane prepared by conventional methods in 90 parts by weight of N,N-dimethylformamide (DMF) to obtain a uniform polyurethane solution with a mass concentration of 10%. ; After adding 30% of its mass of silicon dioxide nanospheres to the polyurethane solution, stir it with magnets for 18 hours at room temperature and in an air atmosphere to obtain a mixed solution, pour the mixed solution into a mold, and heat up to 80° C. in a vacuum oven. Vacuum is 10 -1 Pa, keep it for 4 hours to complete the solvent volatilization, and obtain the polyurethane film.

[0029] Wherein: silica nanospheres r...

Embodiment 2

[0031] Example 2 A controllable self-curling polyurethane film, which is composed of a polyurethane layer and a polyurethane-silicon dioxide nanosphere composite layer, with a thickness of 80 μm. The polyurethane-silica nanosphere composite layer accounts for 70% of the total thickness of the membrane material.

[0032] Its preparation method refers to: dissolving 20 parts by weight of solid polyurethane prepared by conventional methods in 80 parts by weight of N-methylpyrrolidone (NMP) to obtain a uniform polyurethane solution with a mass concentration of 20%; in the polyurethane solution After adding 60% of its mass of silica nanospheres, stir for 12 hours under normal temperature and air atmosphere to obtain a mixed solution, pour the mixed solution into a mold, and heat up to 100°C in a vacuum oven with a vacuum degree of 10Pa , keep 2h to complete the solvent volatilization, that is, the polyurethane film.

[0033] Wherein: silica nanospheres refer to monodisperse nanosp...

Embodiment 3

[0035] Example 3 A controllable self-curling polyurethane film, which is composed of a polyurethane layer and a polyurethane-silicon dioxide nanosphere composite layer, with a thickness of 50 μm. The polyurethane-silica nanosphere composite layer accounts for 60% of the total thickness of the membrane material.

[0036] Its preparation method refers to: dissolving 15 parts by weight of solid polyurethane prepared by conventional methods in 85 parts by weight of N,N-dimethylformamide (DMF) to obtain a uniform polyurethane solution with a mass concentration of 15%. ; After adding 40% of its mass of silicon dioxide nanospheres to the polyurethane solution, stir it with magnets for 20 hours at room temperature and in an air atmosphere to obtain a mixed solution, pour the mixed solution into a mold, and heat up to 50° C. in a vacuum oven. The degree of vacuum is 1Pa, keep it for 10h to complete the solvent volatilization, and obtain the polyurethane film.

[0037] Wherein: silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com