A maintenance equipment for pipelines laid underground or crossing rivers

A technology for repairing equipment and crossing rivers, applied in mechanical equipment, pipe components, pipeline systems, etc., can solve problems such as high cost and increased cost, and achieve the effects of scientific and reasonable structure, improved work efficiency, and safe and convenient use.

Active Publication Date: 2021-03-19

LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention provides a maintenance equipment for pipelines laid underground or crossing rivers, which can effectively solve the common internal pipeline repair methods proposed in the above-mentioned background technology, including: repairing underground cast iron pipeline joints without trenches, in-situ solidification lining method, polymer Ester pipe flipping lining method, etc., the current internal repair methods in China include U-shaped HDPP pipe lining repair method, in-situ curing repair method, coating lining repair method, expansion pipe method pipeline repair, etc. These methods generally show as follows: Off-line repair; the medium in the pipeline needs to be removed, which has high requirements for the working environment; some repair methods will bring about a large change in the inner diameter of the pipeline; some repair solutions require high-cost professional equipment, which increases the cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

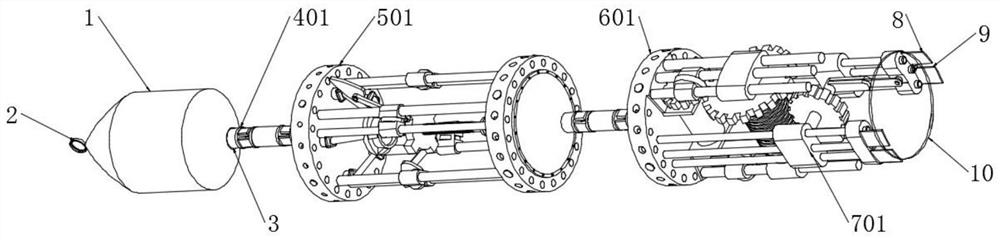

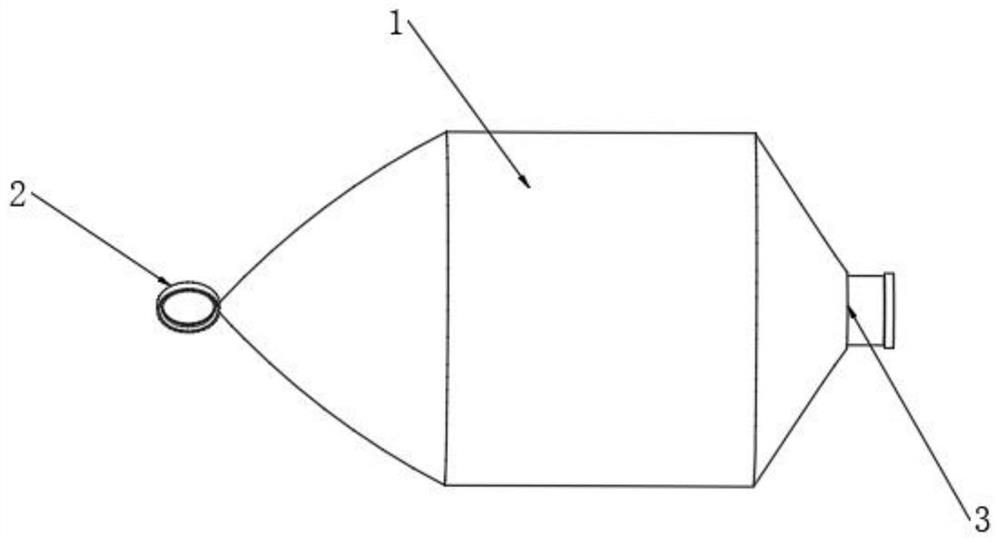

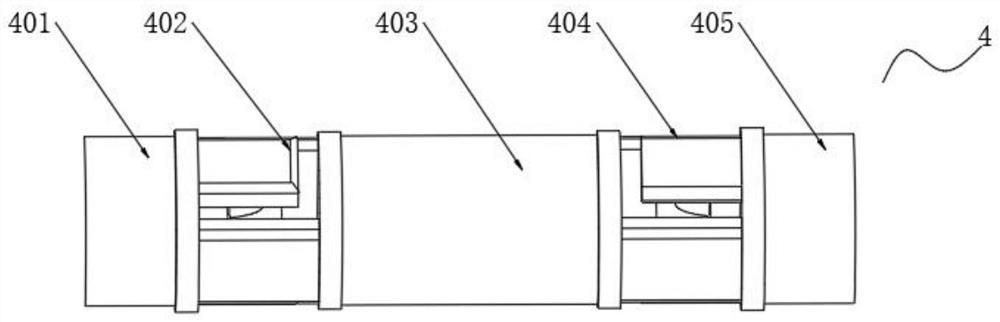

[0039] Embodiment 1: as Figure 1-6 As shown, the present invention provides a technical solution, a maintenance equipment for pipelines laid underground or crossing rivers. A connecting component 4 is installed between the components 5, and the connecting component 4 includes a first connecting column 401, a first universal joint 402, a central column 403, a second universal joint 404 and a second connecting column 405;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses maintenance equipment for pipelines under the conditions of buried laying or crossing rivers, comprising a detection head, wherein one side of the detection head is provided with a brake assembly; one side of the brake assembly is provided with a push assembly; the maintenance equipment provided by the invention has a scientific and reasonable structure, is safe and convenient to use, is provided with a brake assembly, and is convenient to drive a cam brake block to open a certain angle, contact with the inner wall of a pipeline and be blocked through a screw rod, a linkage, a brake motor, a brake block connecting rod and the cam brake block; in order to realize the braking action, when unlocking is required after the repair work is completed, the cam brake block isdriven to return to a normal state through the reverse motion of the brake motor to complete the unlocking action; the push assembly is arranged, and a sliding block is convenient to move back and forth through the action of a worm wheel shaft, a worm wheel, a crank, the connecting rod and the sliding block to realize the pushing of a repair ring; through the action of a repair ring clamping piece, the repair ring is convenient to fix and the repair work is prevented from being affected by the shaking of the repair ring.

Description

technical field [0001] The invention relates to the technical field of pipeline detection and maintenance, in particular to maintenance equipment for pipelines laid underground or crossing rivers. Background technique [0002] Due to the advantages of safety, efficiency and economy, pipeline transportation has become the main means of transportation for oil and gas transportation in the world. Due to factors such as the increase in the service life of pipelines, external force interference, corrosion or material defects caused by immature early materials, pipelines The problem of failure is becoming more and more serious. Since most of China's oil pipelines cross rivers and are laid underground, once corrosion, perforation, leakage and other problems occur in the above working conditions, the pipeline must be stopped and excavated to repair the pipeline, resulting in huge economic losses. Pipeline inspection and repair, a lot of work has been carried out at home and abroad. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L55/163F17D5/02

Inventor 包瑞新潘振马贵阳张辉栗佳李宪臣陈子洋柯奉志孙孟缘靳皓阳李树东

Owner LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com