High-power optical fiber beam combiner suitable for thermal vacuum environment

A fiber combiner, high-power technology, applied in the coupling of optical waveguides, fiber mechanical structure, etc., can solve problems such as device burnout, and achieve the effects of easy packaging, improved plasticity, and stable operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

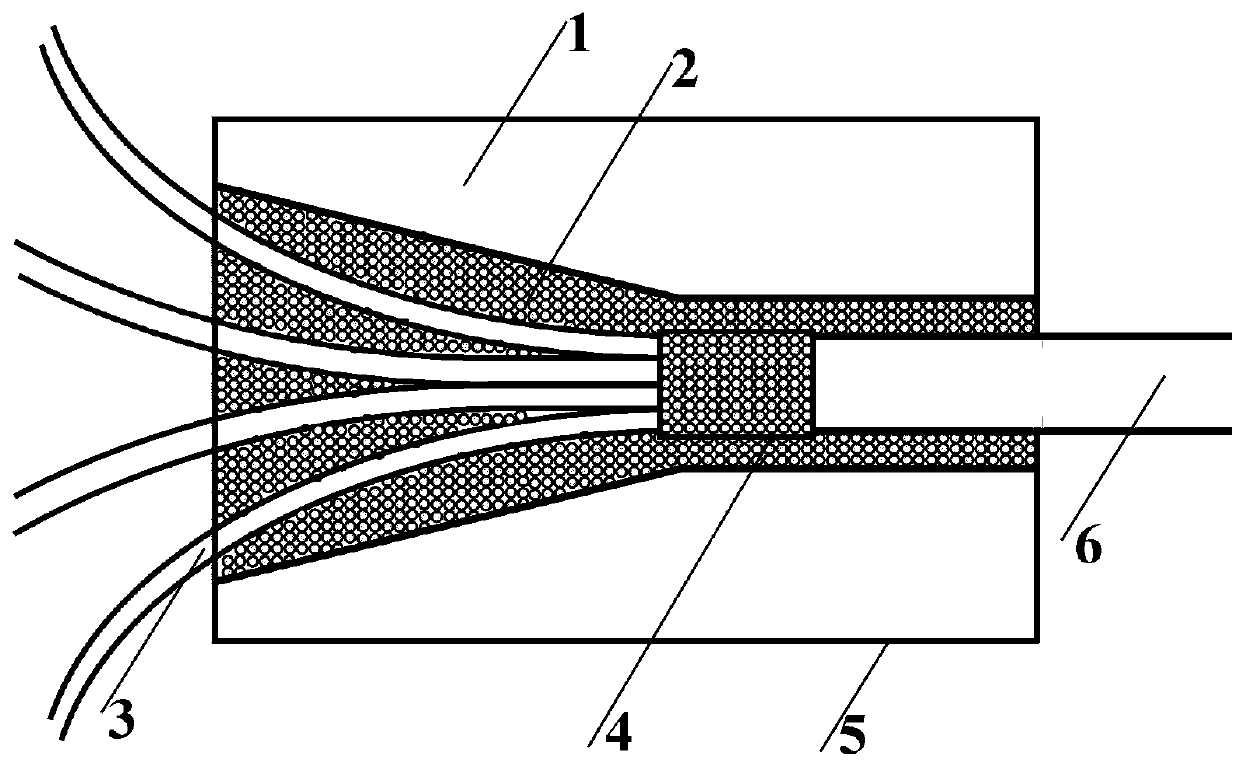

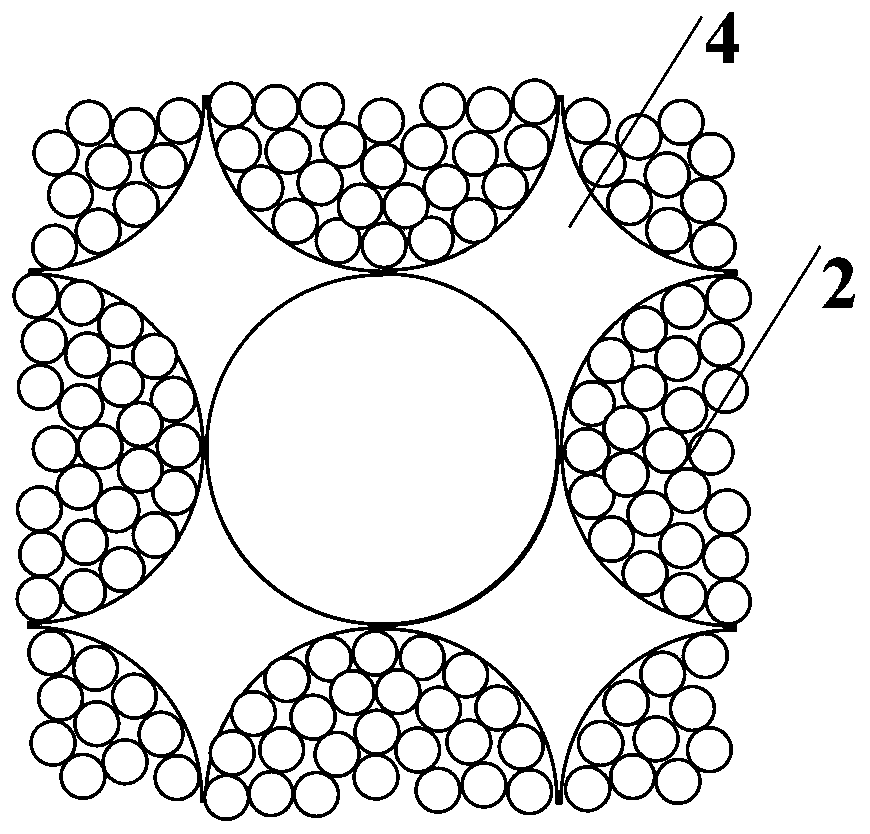

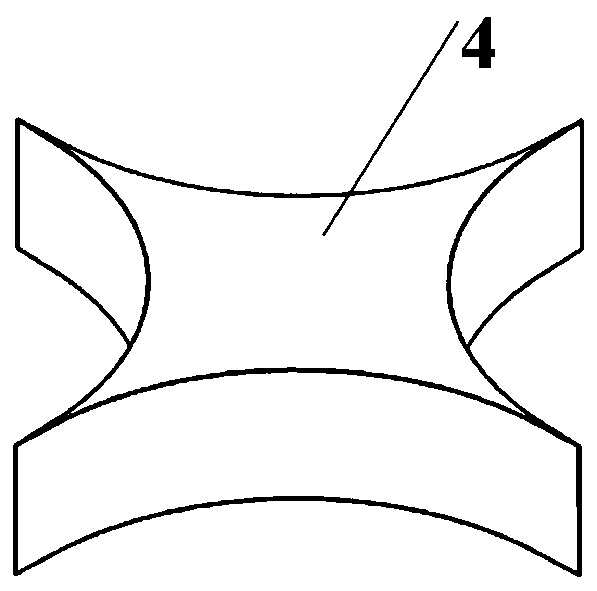

[0020] Such as figure 1 , as shown, the present invention provides a fiber combiner suitable for thermal vacuum environment, including 1. heat sink layer, 2. micro metal balls, 3. input optical fiber, 4. heat conducting medium, 5. packaging box, 6. Output fiber. The input optical fiber 3 and the output optical fiber 6 are connected by fused taper and placed in the packaging box 5. The inner circumference of the packaging box is provided with a heat sink layer 1, and the outer circumference of the tapered area is provided with a heat conduction medium 4. Between the heat sink layer and the heat conduction Micro metal balls 2 are tightly filled between the media.

[0021] The thermal vacuum high-power fiber bundle combiner proposed by the present invention is based on the heat transfer characteristics of solids. First, the input fiber and the output fiber are connected by fusion tapering to form a connector with a tapered area, and the connector is placed in the packaging box,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com