An online soft measurement method for the concentration of gas components in the hearth of a residue gasifier

A gas component and gasifier technology, applied in the field of online soft measurement of gas component concentration in the residual oil gasifier furnace, can solve the problems that the gas component content cannot be directly measured, affecting the production process and the quality of syngas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In actual application, the present invention timely and accurately provides operators with real-time data of gas components in the furnace and determines the reaction status in the furnace by receiving and collecting data, programming calculations, and outputting gas component concentration information in the furnace. The following will be combined with the accompanying drawings The present invention is further described with embodiment:

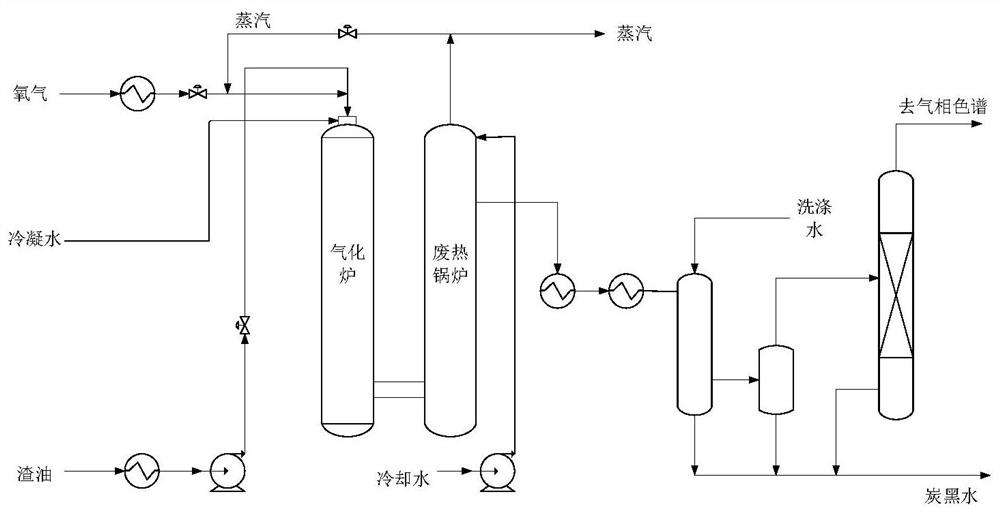

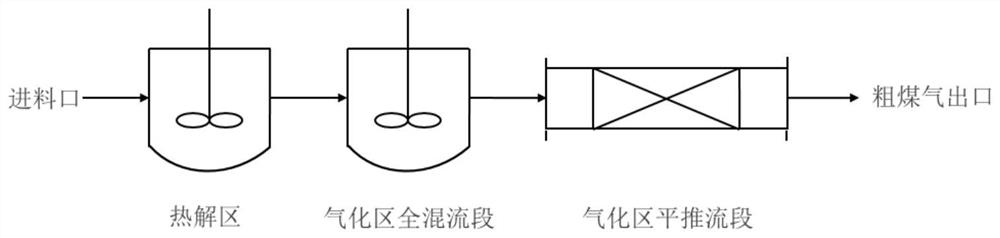

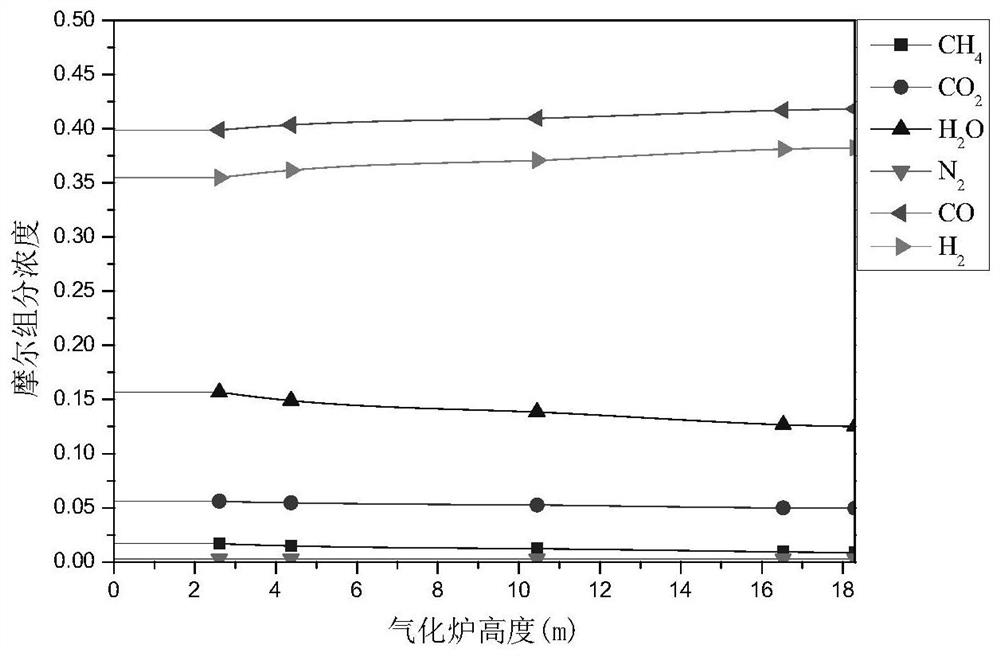

[0076] Example The gasification device of a petrochemical enterprise is selected. The height of the gasification furnace is 18.3m, the diameter is 2.452m, the operating pressure is about 6MPa, the gasification temperature is about 1250-1350°C, there are few by-products, and the effective gas in the syngas Yield (CO+H 2 ) can reach about 90%. The existing flow chart of Shell residual oil gasification process in a petrochemical enterprise is as follows figure 1 As shown, after the residual oil is pressurized by the pump and preheated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com