An electric field traction ultrafast laser thermal cracking processing device and method for hard and brittle materials

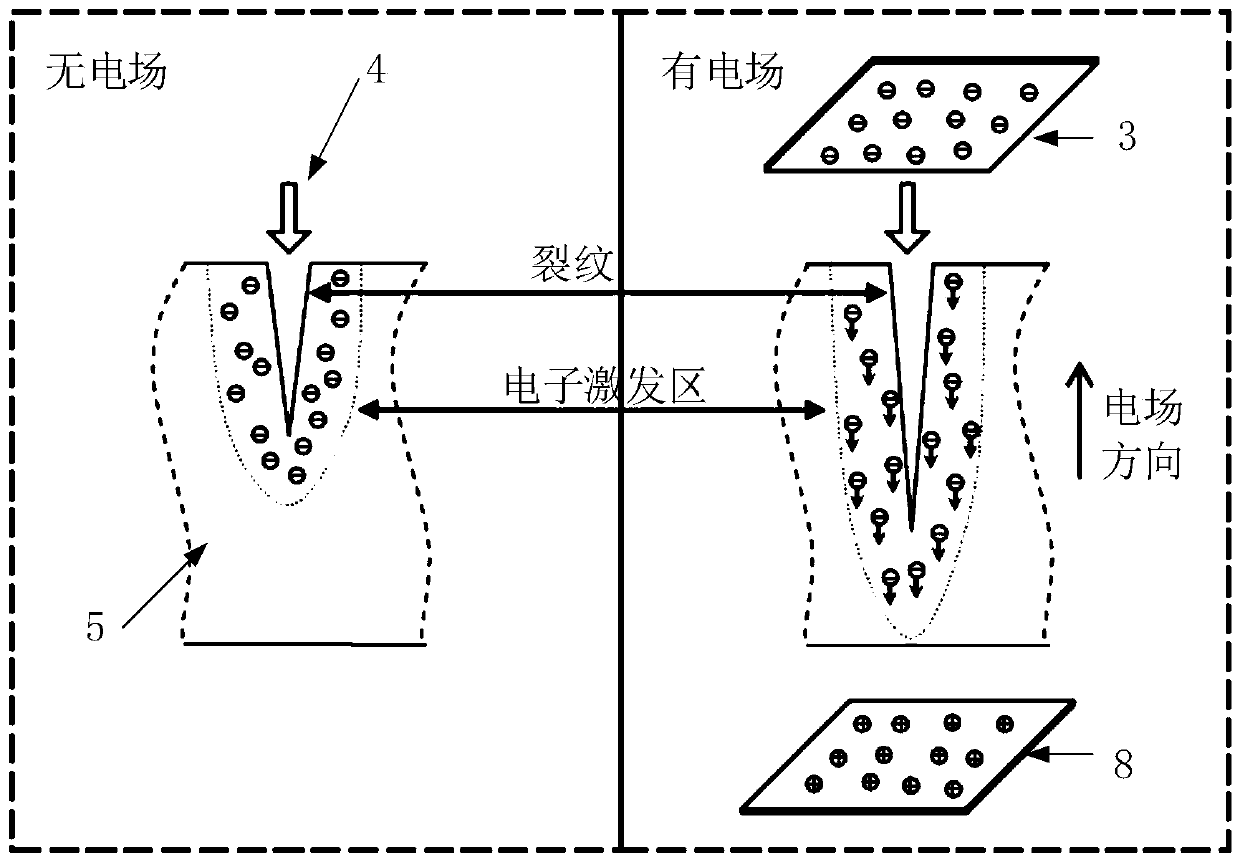

A technology of ultra-fast laser and hard and brittle materials, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of insufficient depth of ultra-fast laser thermal cracking and extended crack depth, etc., and achieve less fragments and less roughness Effect of small, debris-free slag burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] [Example 1] Workpiece processing of glass material, thickness 2mm, electro-acoustic coupling time > 20ps

[0034] Step 1: Device Arrangement:

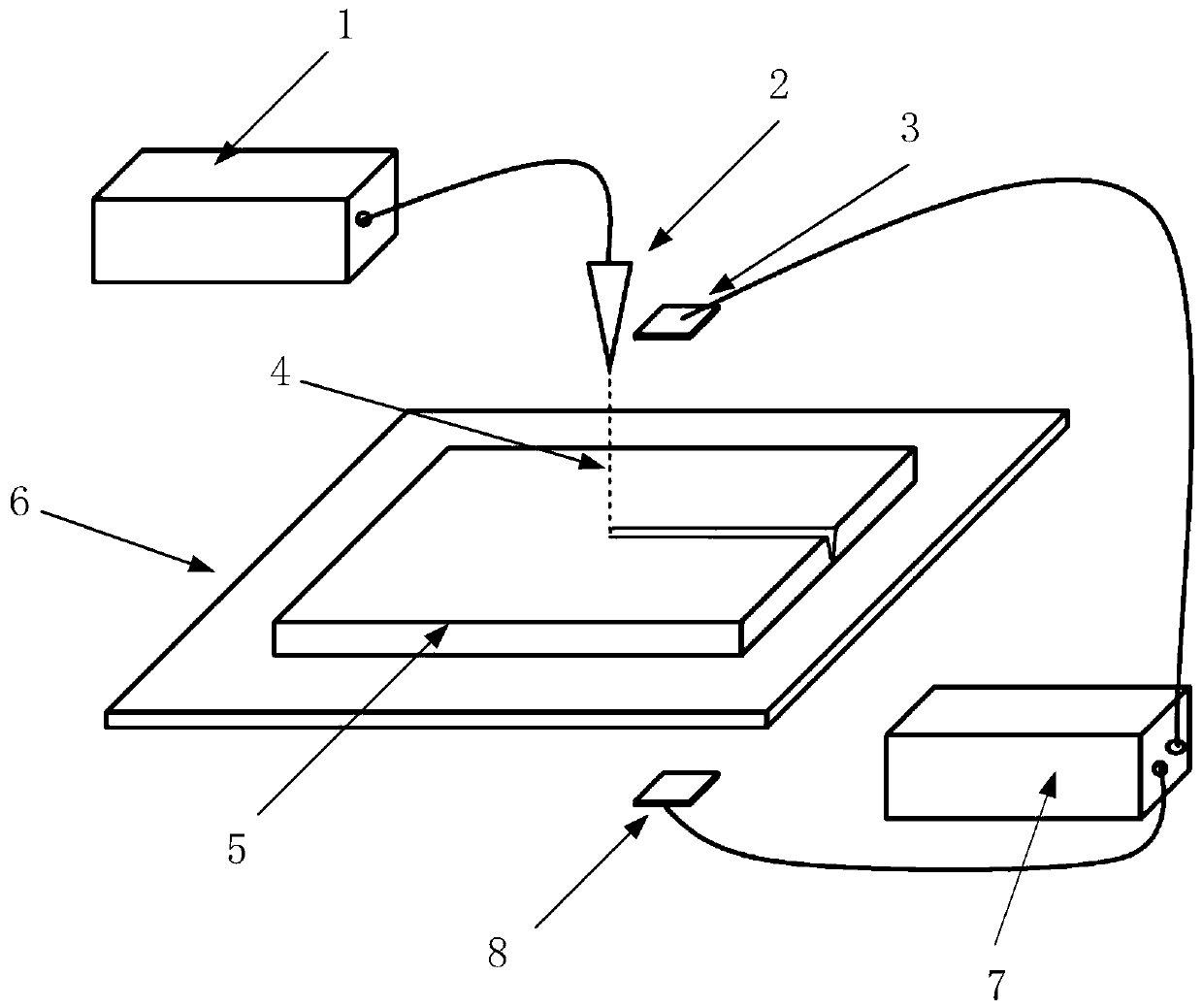

[0035] The cathode plate 3 and the laser head 2 are arranged above the workpiece 5 to be processed on the front of the insulating support plate 6, and the anode plate 8 is positioned at the back side of the insulating support plate 6 and faces the cathode plate 3; adjust the position of the laser head 2 or the cathode plate 3 so that the laser head 2. It is always located directly in front of the cathode plate 3 on the processing path, and the laser beam is positioned at the edge of the cathode plate 3.

[0036] Step 2: Parameter setting:

[0037] Ultrafast laser process parameters: power 50W, wavelength 355nm, pulse width 10ps, repetition frequency 50kHz, focus on the surface of the material;

[0038] Electric field parameters: adjust the distance between the cathode plate 3 and the anode plate 8 to 0.5cm, and the output volt...

example 2

[0042] [Example 2] Workpiece processing of sapphire material, thickness 3mm, electroacoustic coupling time > 80ps

[0043] Step 1: Device Arrangement:

[0044] The cathode plate 3 and the laser head 2 are arranged above the workpiece 5 to be processed on the front of the insulating support plate 6, and the anode plate 8 is positioned at the back side of the insulating support plate 6 and faces the cathode plate 3; adjust the position of the laser head 2 or the cathode plate 3 so that the laser head 2. It is always located directly in front of the cathode plate 3 on the processing path, and the laser beam is positioned at the edge of the cathode plate 3.

[0045] Step 2: Parameter setting:

[0046] Ultrafast laser process parameters: power 100W, wavelength 532nm, pulse width 70ps, repetition frequency 200kHz, focus on the surface of the material;

[0047] Electric field parameters: adjust the distance between the cathode plate 3 and the anode plate 8 to 1 cm, and the output v...

example 3

[0051] 【Example 3】Workpiece processing of ceramic material, thickness 5mm, electro-acoustic coupling time > 200ps

[0052] Step 1: Device Arrangement:

[0053] The cathode plate 3 and the laser head 2 are arranged above the workpiece 5 to be processed on the front of the insulating support plate 6, and the anode plate 8 is positioned at the back side of the insulating support plate 6 and faces the cathode plate 3; adjust the position of the laser head 2 or the cathode plate 3 so that the laser head 2. It is always located directly in front of the cathode plate 3 on the processing path, and the laser beam is positioned at the edge of the cathode plate 3.

[0054] Step 2: Parameter setting:

[0055] Ultrafast laser process parameters: power 200W, wavelength 1064nm, pulse width 180ps, repetition frequency 450kHz, focus on the surface of the material;

[0056] Electric field parameters: adjust the distance between the cathode plate 3 and the anode plate 8 to 4cm, and the voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com