Multi-channel feeding ribbon production system and production method thereof

A production system, multi-channel technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve problems such as difficult degradation, environmental pollution, and no practical value of rake materials, and achieve rapid crushing, good crushing effect, and reduce The effect of cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

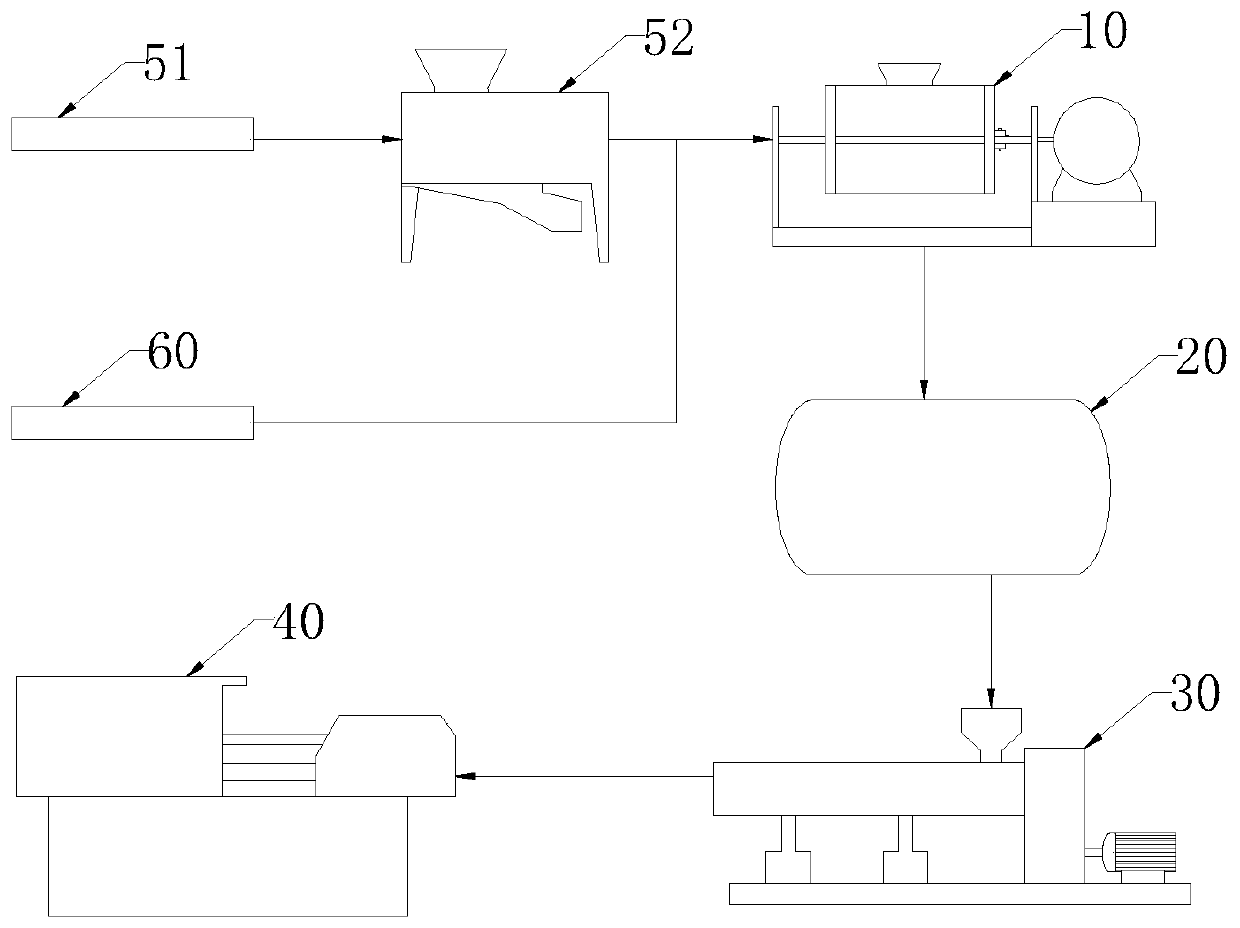

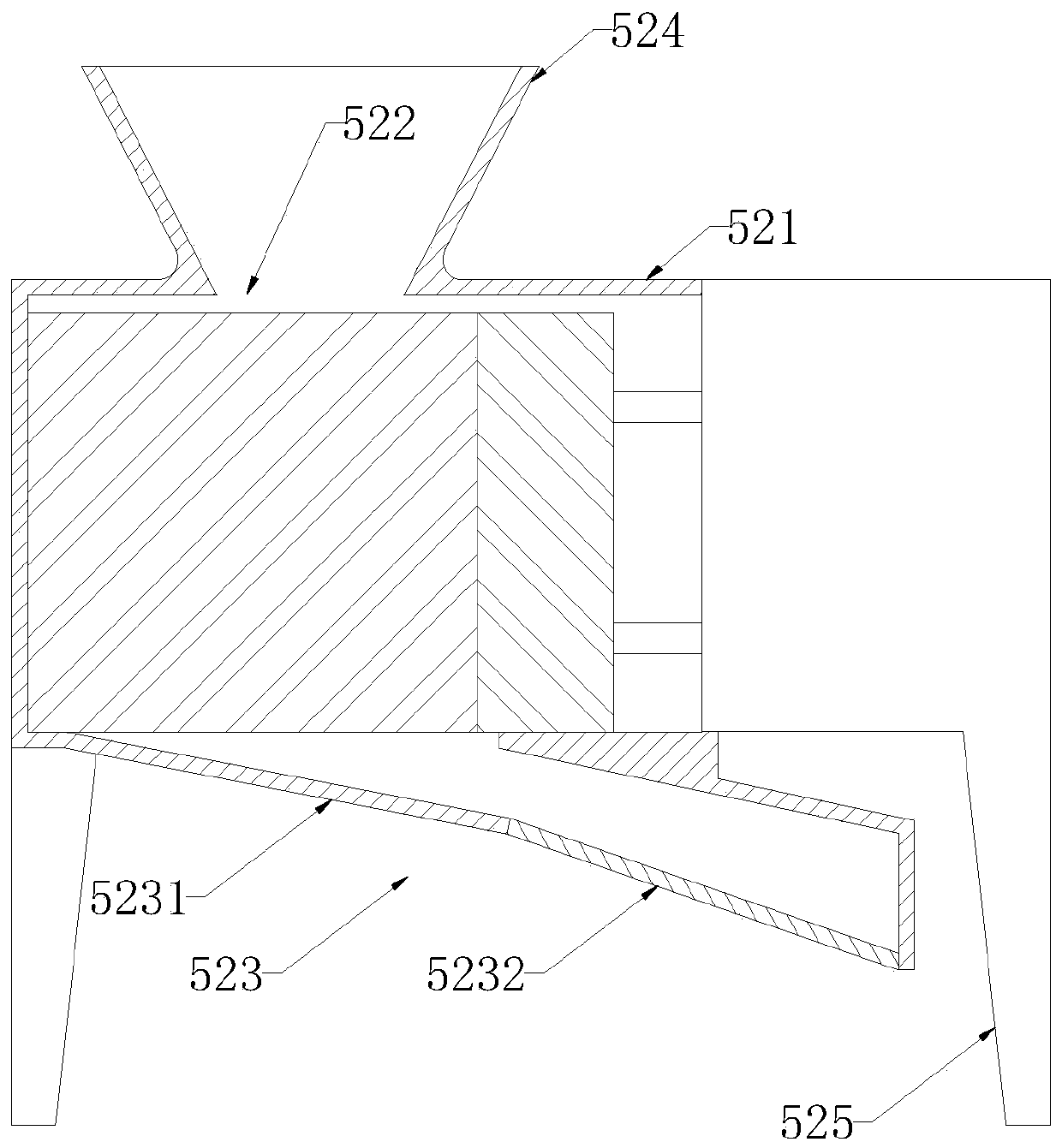

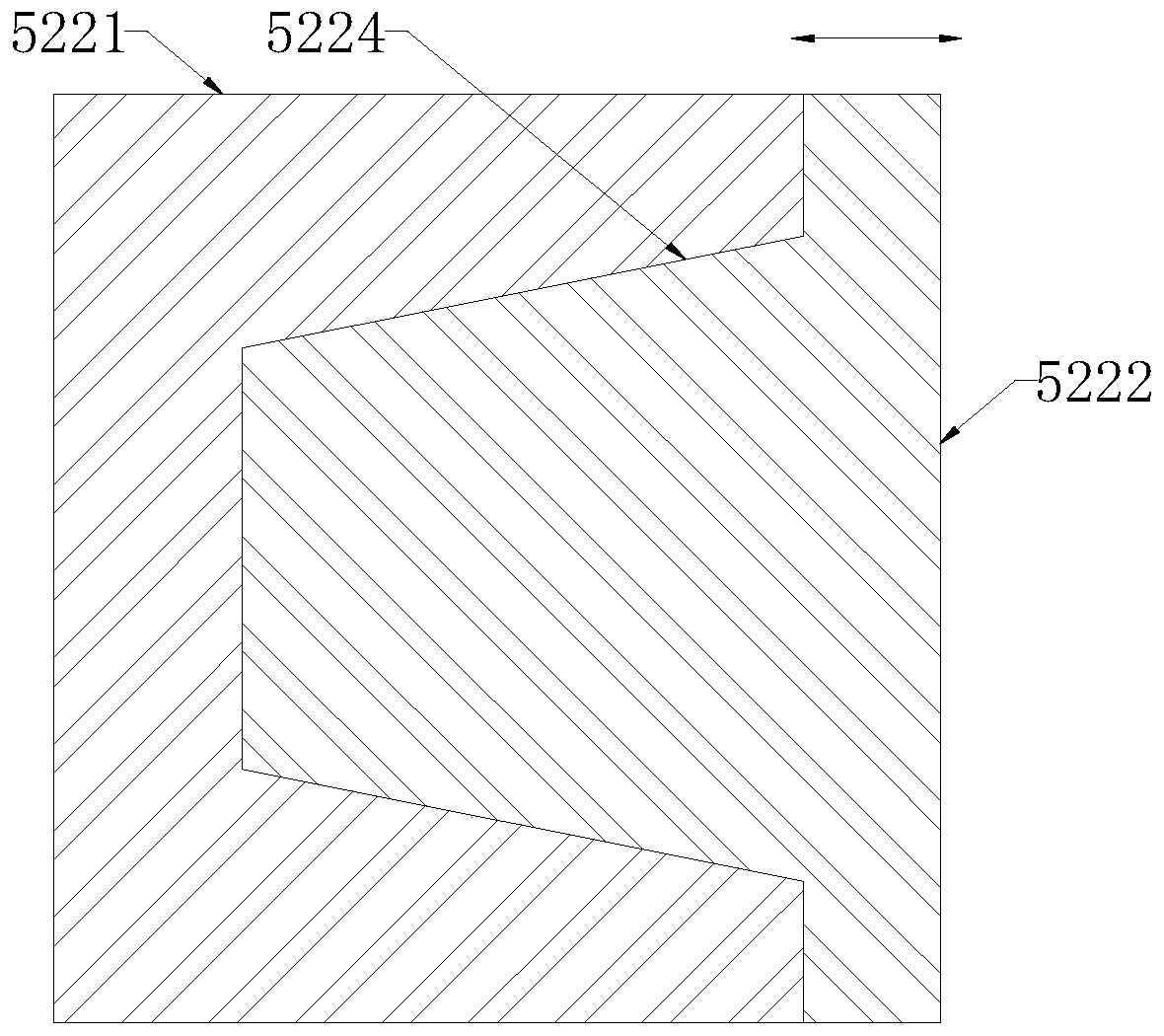

[0037] Such as figure 1 As shown, a cable tie production system with multi-channel feeding includes a recycled material supply line, a raw material masterbatch supply line, a mixer 10, a dryer 20, an extruder 30 and an injection molding machine 40, and the recycled material is supplied Line, raw material masterbatch supply line are set up in parallel, and set up in series with mixer 10, drier 20, extruder 30 and injection molding machine 40, described recycled material supply line includes recycled material weighing scale 51 and crushing from recycled material The crushing machine 52 of the recovered material of the weighing scale 51, the raw material masterbatch supply line includes a masterbatch weighing scale 60, and both the crusher 52 and the masterbatch weighing scale 60 deliver the mixed material to the mixer 10 through a material conveyor .

[0038] The cable tie production system with multi-channel feeding of the present invention realizes the mixing of raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com