Multi-rotor unmanned aerial vehicle design method

A technology of a multi-rotor drone and a design method, which is applied in aircraft assembly, aircraft parts, metal processing equipment, etc., can solve the problems of unmanned aerial vehicles that cannot be mass-produced and assembled quickly, low economic benefits, and low component utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

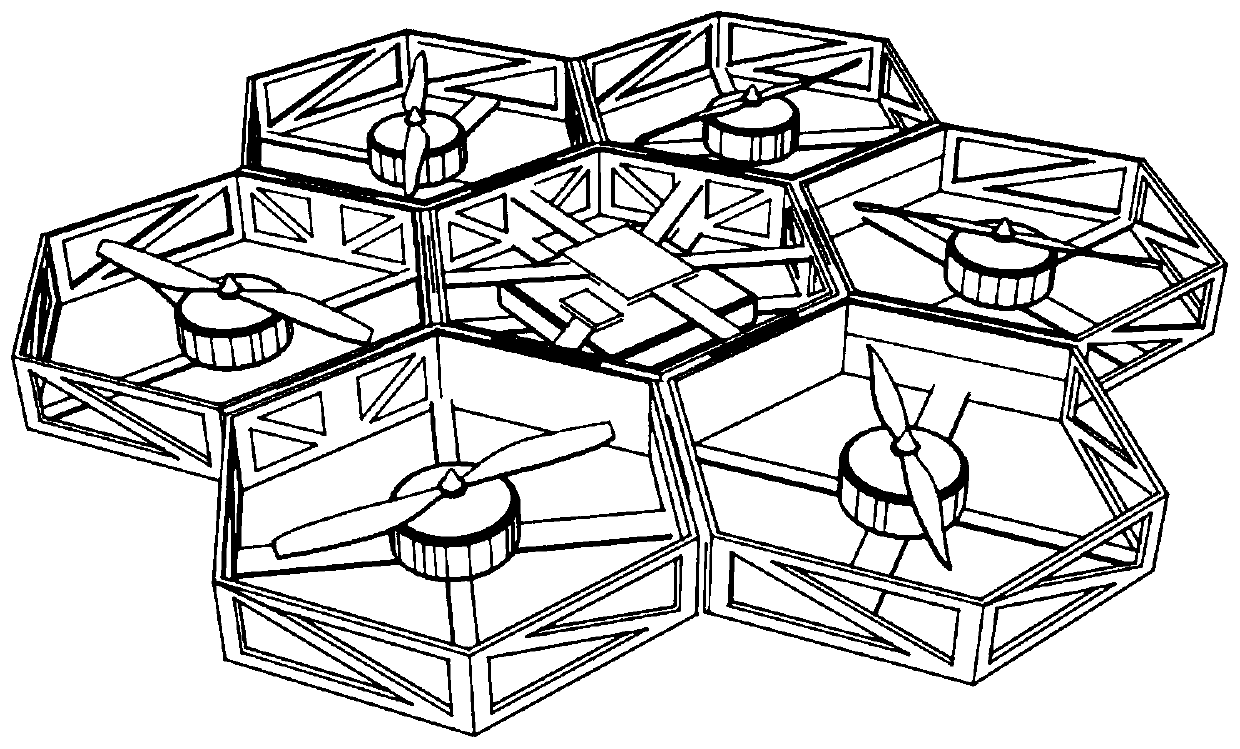

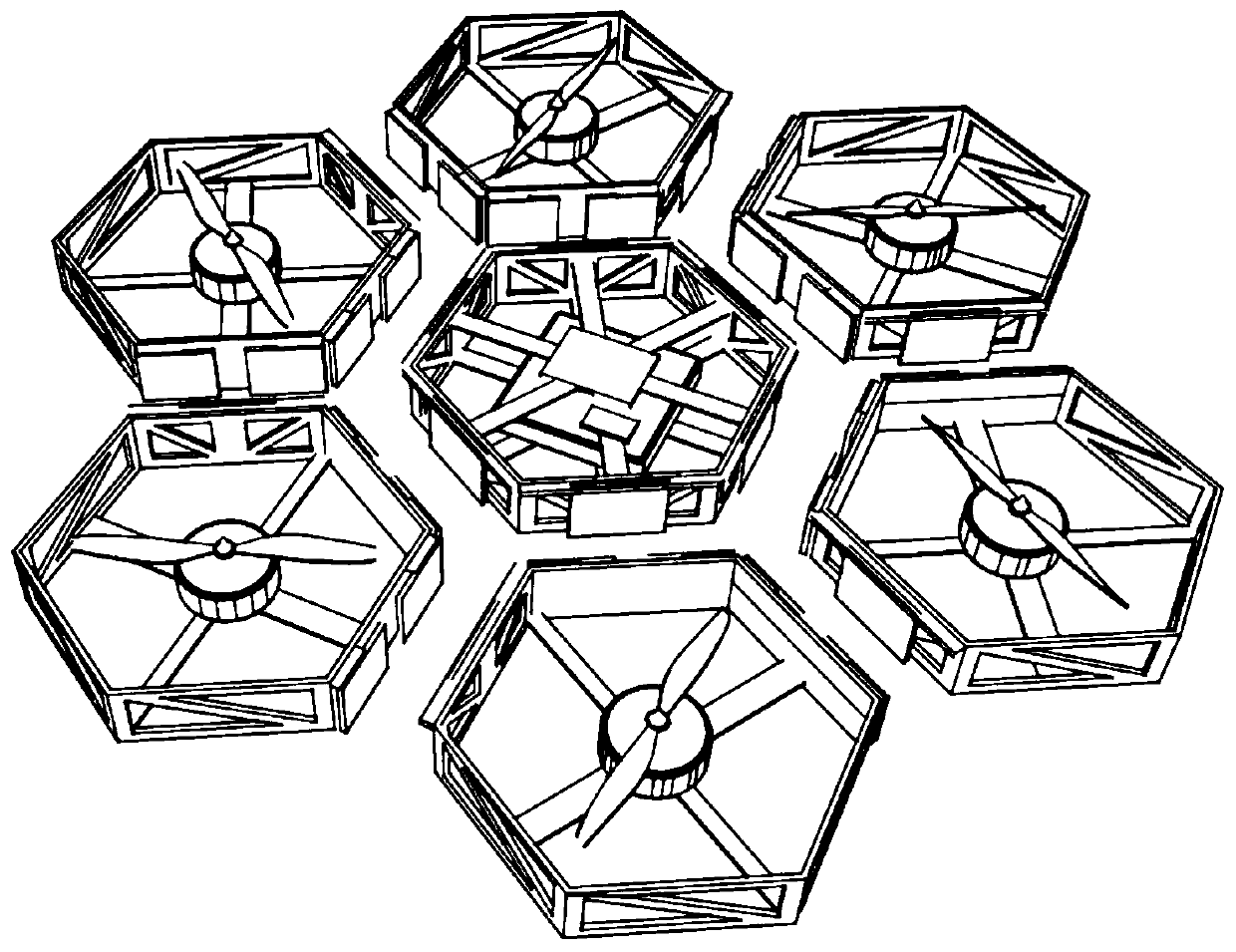

[0020] Such as figure 1 , 2 , 3, and 4, the portable, modular, and expandable 3D printed multi-rotor UAV includes 1 central control box assembly and 6 power box assemblies. The central control box assembly and the power box assembly respectively adopt a hexagonal structure, which is a hexagonal shape when viewed from the front. The central control box assembly is in the middle, and a power box assembly is plugged and connected to each side of the central control box assembly. , and plug connection between every two adjacent power boxes.

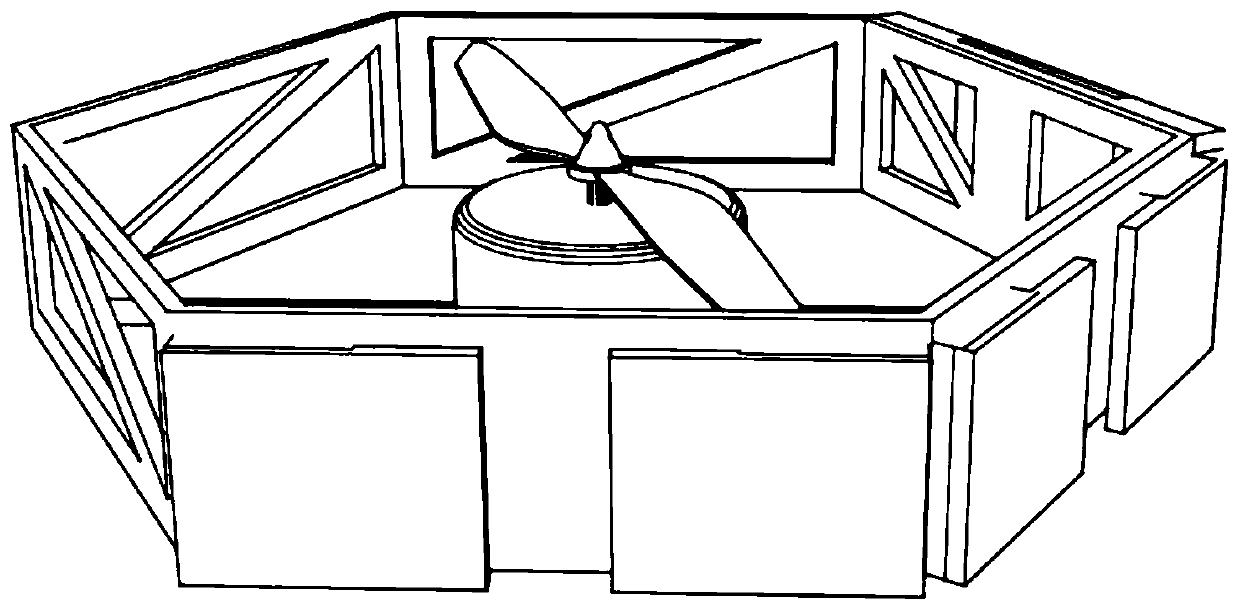

[0021] Such as Figure 5 As shown, the structure of the six power box assemblies is exactly the same. The power box assembly includes the main body of the power box 4, the motor base 3, the rotor 2, and the nut 1. A connecting piece for plugging is designed on the side connected to the central control box assembly , on the two sides next to each other, one side is designed with a connecting block 5 for plugging with the connecting piece 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com