Silicone emulsion for surface smooth treatment of synthetic leather and artificial leather and preparation method thereof

A silicone emulsion, surface smooth technology, applied in fiber treatment, textile and papermaking, improved hand fiber, etc., can solve the problems of demulsification, poor leather adhesion, oil spots on the finished leather surface, etc., to achieve stability Good, good printability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

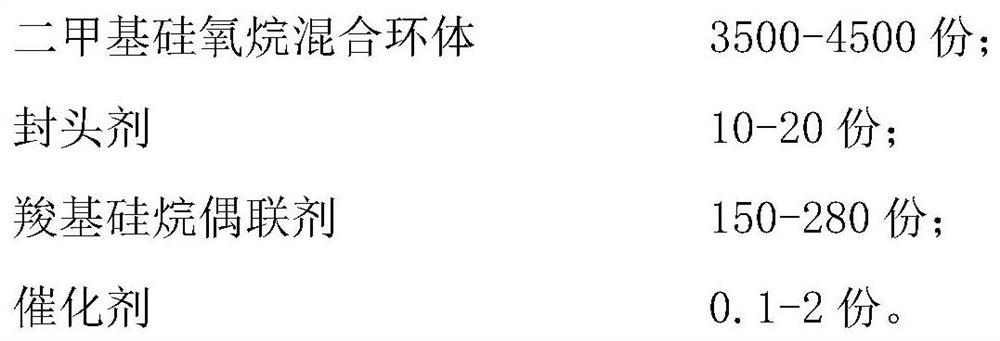

[0028] Carboxylic silicone oil crude oil preparation:

[0029] Mix and polycondense octamethylcyclotetrasiloxane, hexamethyldisiloxane, carboxysilane coupling agent and acidic cation exchange resin in a container, the mass ratios are 4000:15:250:1 respectively, the polycondensation reaction The temperature was 120°C and the reaction time was 4 hours. After distillation under reduced pressure, the desired carboxyl silicone oil crude oil was obtained. In this embodiment, the general formula of the carboxysilane coupling agent used is Si-PEG-COOH, specifically (OMe)3Si(CH2)2NHCONH(CH2)2(EO)mCOOH, wherein m≥3.

[0030] Carboxylic silicone oil emulsion preparation:

[0031] Put the prepared carboxy silicone oil crude oil, fatty alcohol polyoxyethylene ether and water into the container, and the mass ratio is 32:4:64 respectively, and carry out mechanical stirring and emulsification at room temperature, the stirring speed is 1000r / min, and the stirring time is 1 hour. A transpare...

Embodiment 2

[0036] Carboxylic silicone oil crude oil preparation:

[0037] Mix and polycondense octamethylcyclotetrasiloxane, hexamethyldisiloxane, carboxysilane coupling agent and acidic cation exchange resin in a container, the mass ratios are 3500:20:250:1 respectively, the polycondensation reaction The temperature was 120°C and the reaction time was 4 hours. After distillation under reduced pressure, the desired carboxyl silicone oil crude oil was obtained. In this embodiment, the general formula of the carboxysilane coupling agent used is Si-PEG-COOH, specifically (OMe)3Si(CH2)2NHCONH(CH2)2(EO)mCOOH, wherein m≥3.

[0038] Carboxylic silicone oil emulsion preparation:

[0039] Add the prepared carboxy silicone oil crude oil, fatty alcohol polyoxyethylene ether and water into the container, and the mass ratio is 33:3:64 respectively, and carry out mechanical stirring and emulsification at room temperature, the stirring speed is 1000r / min, and the stirring time is 1 hour. A transpare...

Embodiment 3

[0044] Carboxylic silicone oil crude oil preparation:

[0045] Mix and polycondense octamethylcyclotetrasiloxane, hexamethylsiloxane, carboxysilane coupling agent and acidic cation exchange resin in a container, the mass ratios are 4500:10:150:1 respectively, the reaction temperature of polycondensation The temperature was 120°C, and the reaction time was 4 hours. After distillation under reduced pressure, the desired carboxyl silicone oil crude oil is obtained. In this embodiment, the general formula of the carboxysilane coupling agent used is Si-PEG-COOH, specifically (OEt)3Si(CH2)2NHCONH(CH2)2(EO)mCOOH, wherein m≥3.

[0046] Carboxylic silicone oil emulsion preparation:

[0047] Put the prepared carboxy silicone oil crude oil, fatty alcohol polyoxyethylene ether and water into the container, the mass ratios are 35:7:58 respectively, carry out mechanical stirring and emulsification at room temperature, the stirring speed is 1000r / min, and the stirring time is 1 hour. A tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com