A kind of pmma toughening agent and high-toughness pmma composition prepared therefrom

A technology of composition and toughening agent, applied in the field of high toughness PMMA composition, can solve the problems such as no functionalized POE toughening modified PMMA and the like, and achieve the effects of low cost, good toughness and good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

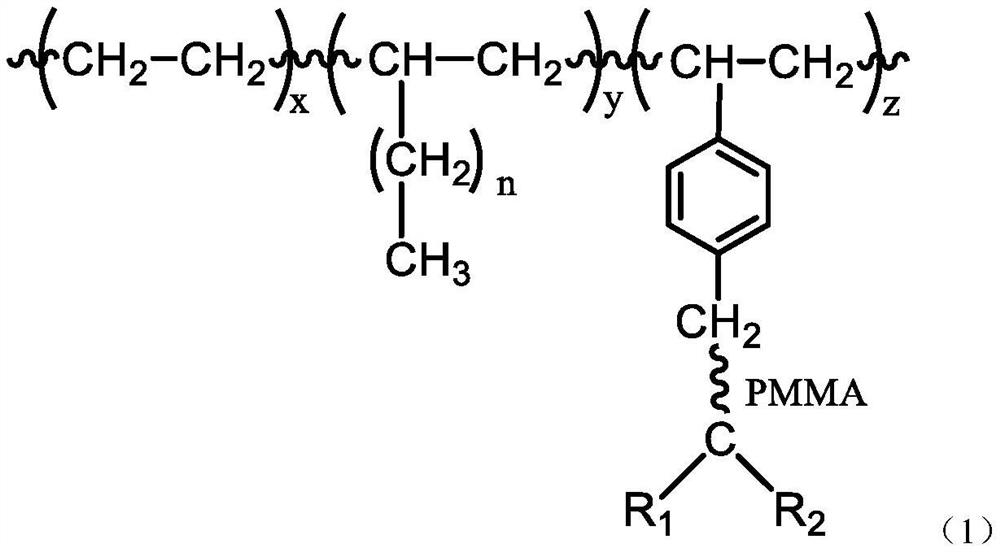

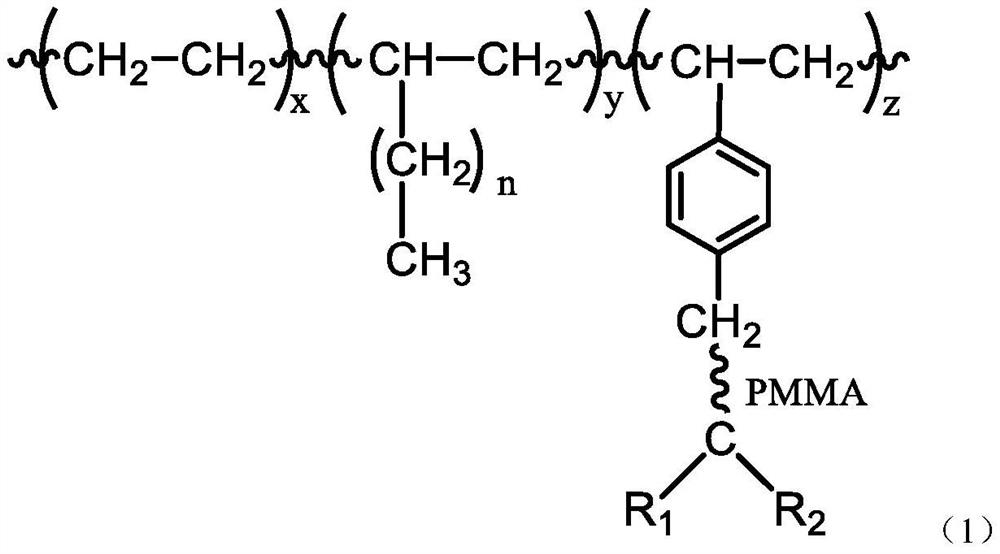

[0038] Weigh 2g of diphenylmethylbenzylstyrene monomer and dissolve it in 300ml of toluene solution, then transfer the above solution to a 500ml reaction kettle and stir evenly. 10 ml of 1-butene was added to the reactor via a syringe while raising the temperature of the reactor to 130°C. Pass into ethylene in the reactor, and by ethylene control the pressure in the reactor is stable at 3MPa, then the metallocene catalyst of the toluene solution 2.6ml of 10Wt% MAO and 2umol adds in the reactor and initiates polymerization reaction, reacts 30min, then The above reaction solution was transferred to acidified ethanol to terminate the reaction to obtain macroinitiator 1 (molecular weight 241846, determined by gel permeation chromatography). Stir and mix the macroinitiator 1 (structure shown in the following formula (3)) with MMA until uniform and heat-treat at 120°C for 8 hours to obtain a toughening agent with a POE segment (molecular weight 432460, through gel permeation chroma...

Embodiment 2

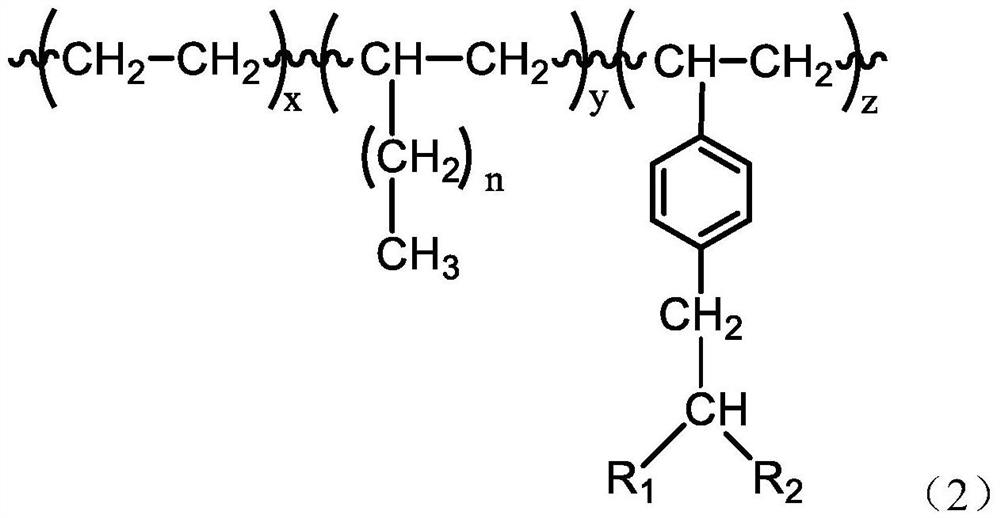

[0041] Weigh 2g of diphenylmethylbenzylstyrene monomer and dissolve it in 300ml of toluene solution, then transfer the above solution to a 500ml reaction kettle and stir evenly. 10 ml of 1-hexene was added to the reactor via a syringe while raising the temperature of the reactor to 140°C. Pass into ethylene in the reactor, and by ethylene control the pressure in the reactor is stable at 3MPa, then the metallocene catalyst of the toluene solution 2.6ml of 10Wt% MAO and 2umol adds in the reactor and initiates polymerization reaction, reacts 30min, then The above reaction solution was transferred to acidified ethanol to terminate the reaction to obtain macroinitiator 2 (molecular weight 242042, determined by gel permeation chromatography). Stir and mix the macroinitiator 2 (structure shown in the following formula (4)) with MMA until uniform and heat-treat at 130°C for 8 hours to obtain a toughening agent with a POE segment (molecular weight 421209, through gel permeation chroma...

Embodiment 3

[0044] Weigh 2g of diphenylmethylbenzylstyrene monomer and dissolve it in 300ml of toluene solution, then transfer the above solution to a 500ml reaction kettle and stir evenly. 10 ml of 1-octene was added to the reactor via a syringe while raising the temperature of the reactor to 160°C. Pass into ethylene in the reactor, and by ethylene control the pressure in the reactor is stable at 3MPa, then the metallocene catalyst of the toluene solution 2.6ml of 10Wt% MAO and 2umol adds in the reactor and initiates polymerization reaction, reacts 30min, then The above reaction solution was transferred into acidified ethanol to terminate the reaction to obtain macroinitiator 3 (molecular weight 244287, determined by gel permeation chromatography). Stir and mix the macroinitiator 3 (structure shown in the following formula (5)) with MMA until uniform and heat-treat at 135°C for 8 hours to obtain a toughening agent with a POE segment (molecular weight 419137, through gel permeation chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com