Unmanned automatic gas extraction system

A gas extraction and automatic technology, applied in gas discharge, mining fluid, mining equipment and other directions, can solve the problems of waste of resources, gas leakage safety, low efficiency, etc., to ensure the extraction power, improve extraction efficiency, and ensure purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

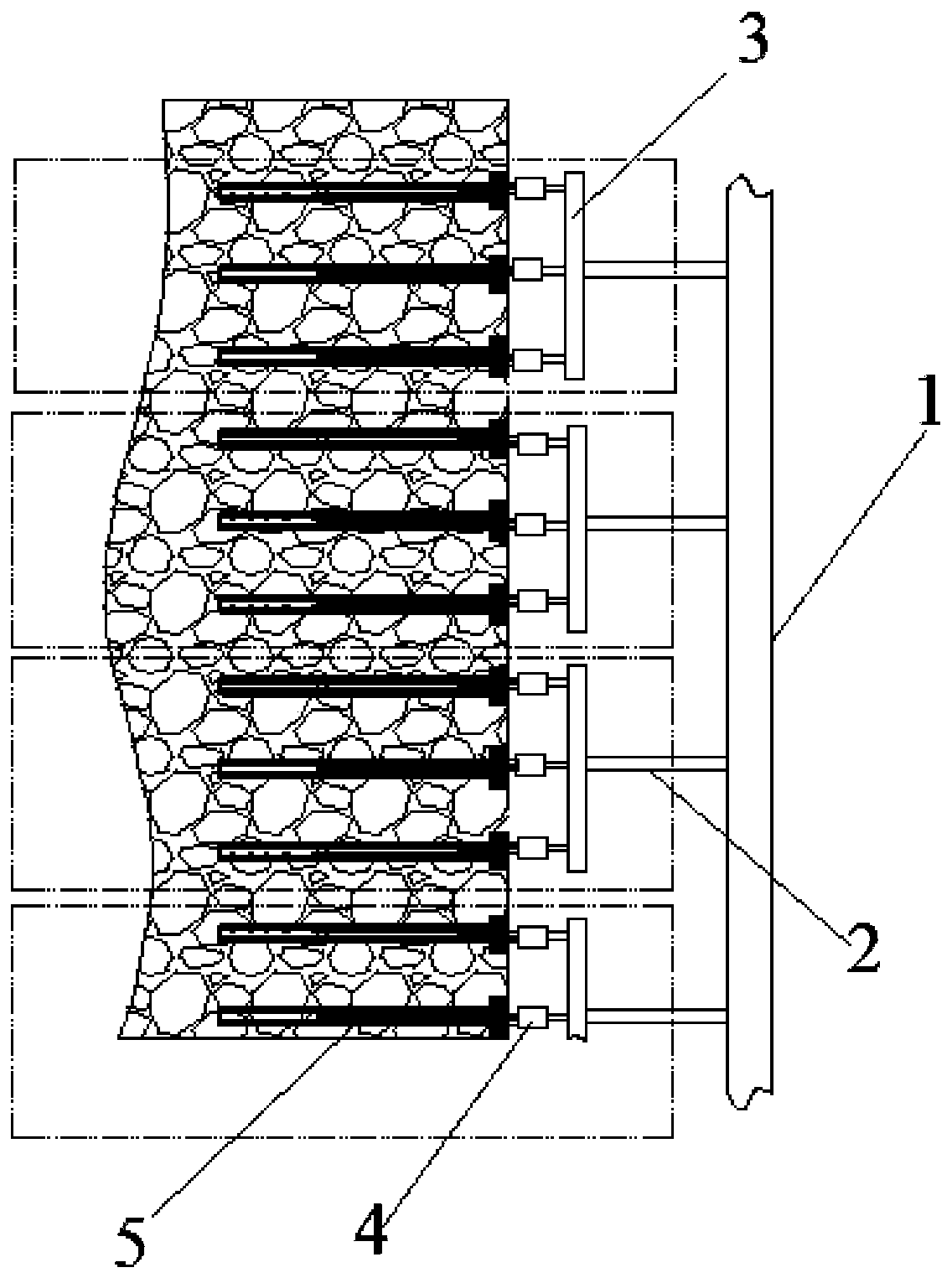

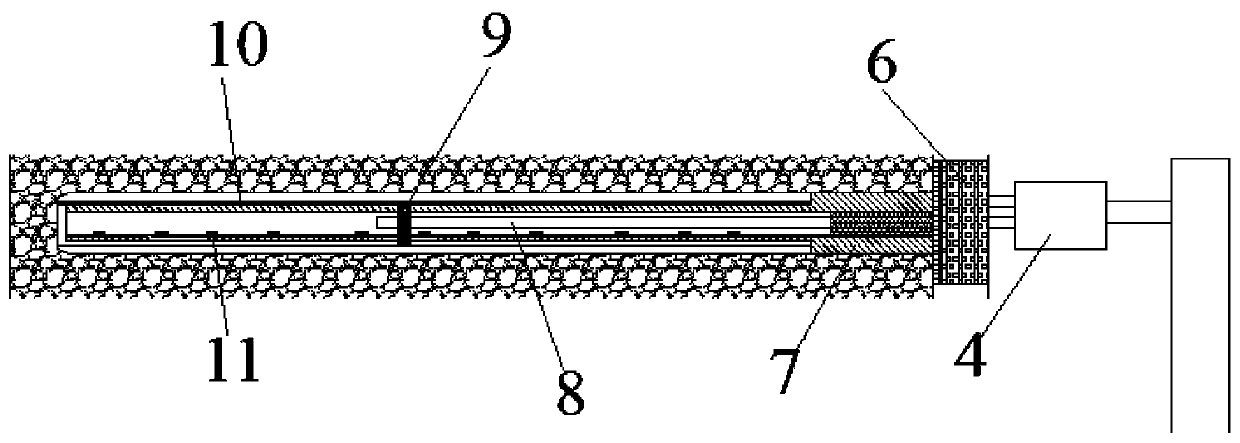

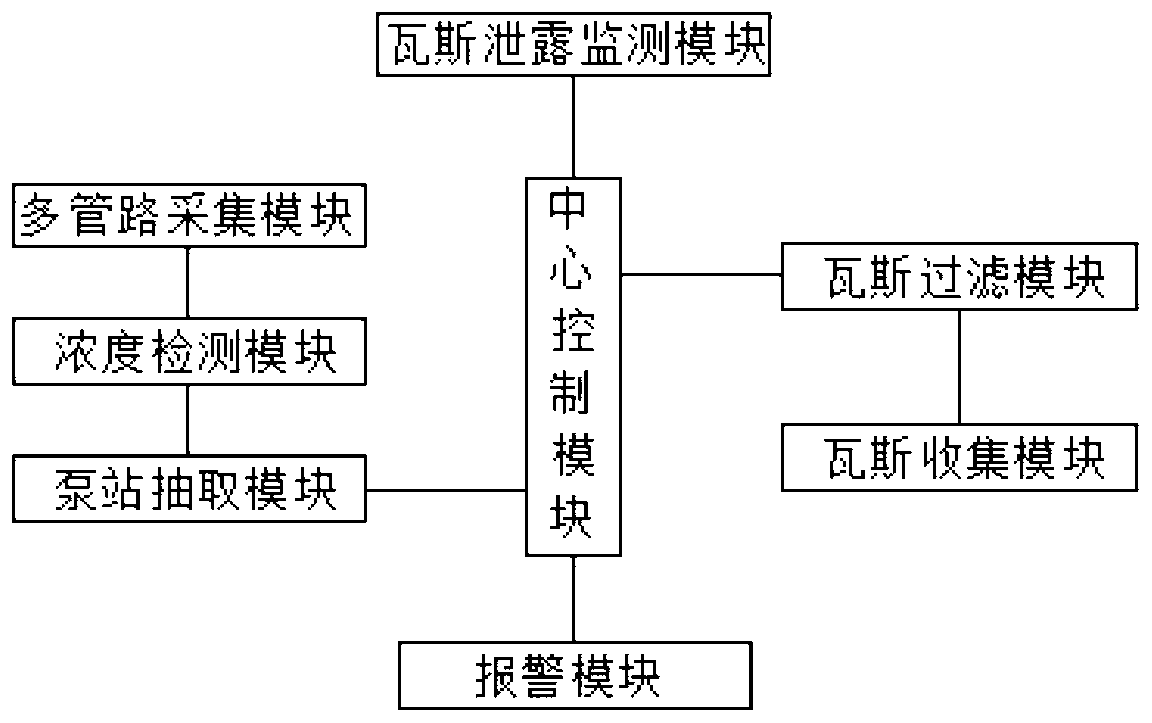

[0032] see Figure 1-3 , in an embodiment of the present invention, an unmanned automatic gas extraction system includes a multi-pipeline acquisition module, a gas concentration detection module, a pumping station extraction module, and a central control module, wherein the multi-pipeline acquisition module is installed Regions are divided into groups such as figure 1 As shown in the dotted line box in , each group includes a plurality of gas drainage pipelines arranged adjacently; the drainage pipe 10 of each gas drainage pipeline extends into the gas drainage borehole of the coal seam, and the gas drainage drill The holes are blocked by the plugging material 7; the gas drainage pipelines of each group are connected in parallel to their respective multi-way connection plates 3, and the multi-way connection plates 3 of each group adopt the drainage negative pressure branch pipes arranged in parallel 2 connected to the extraction negative pressure main pipe 1; the extraction n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com