Electromagnetic vibration recovered energy tuned mass damper

A technology for tuning mass damping and recovering energy, which is applied in the direction of shock absorbers, electric components, inertial effect dampers, etc., can solve the problems of less recovered energy, unfavorable miniaturization, and lack of compact characteristics, etc., to improve the road Retention, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

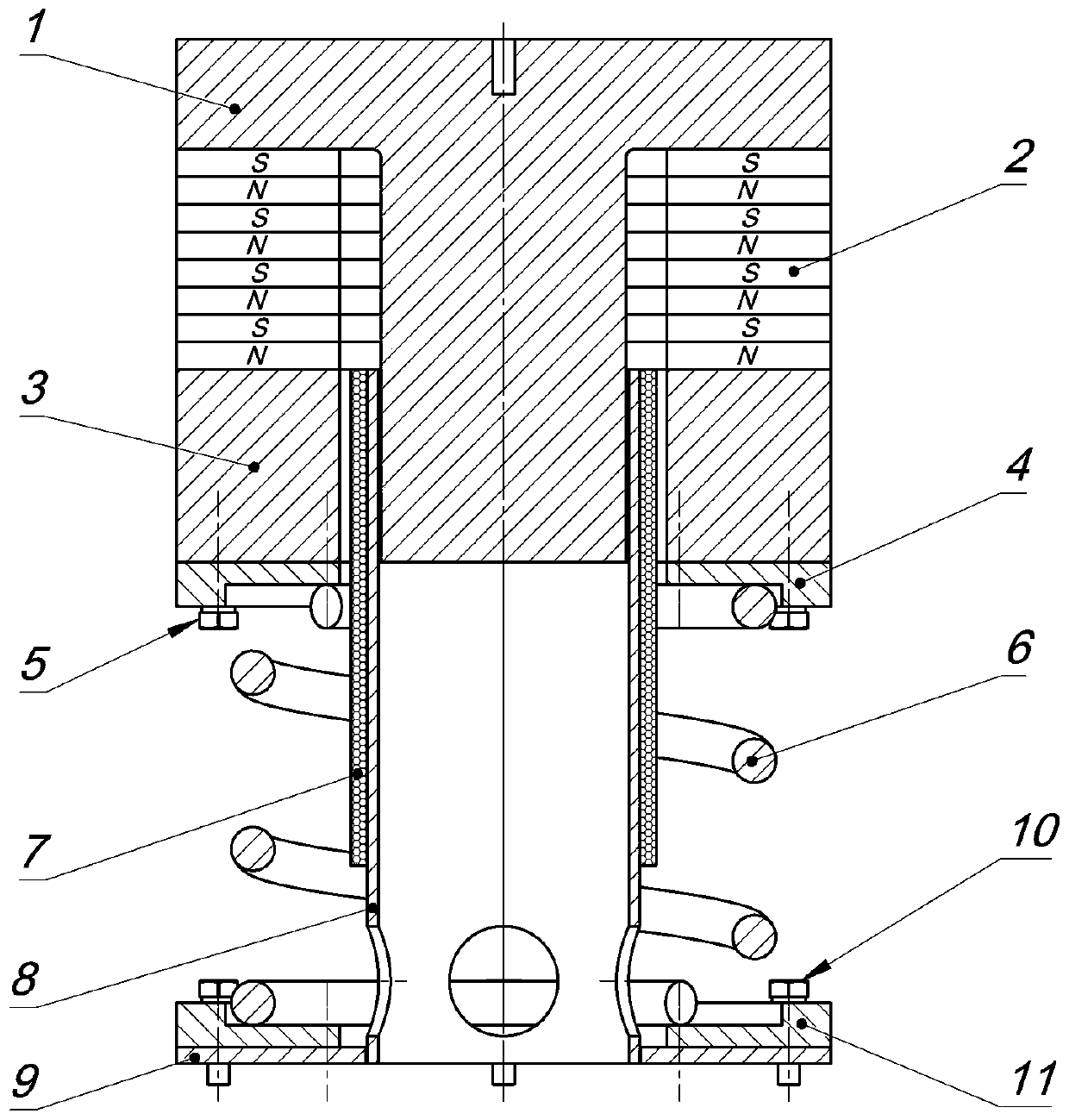

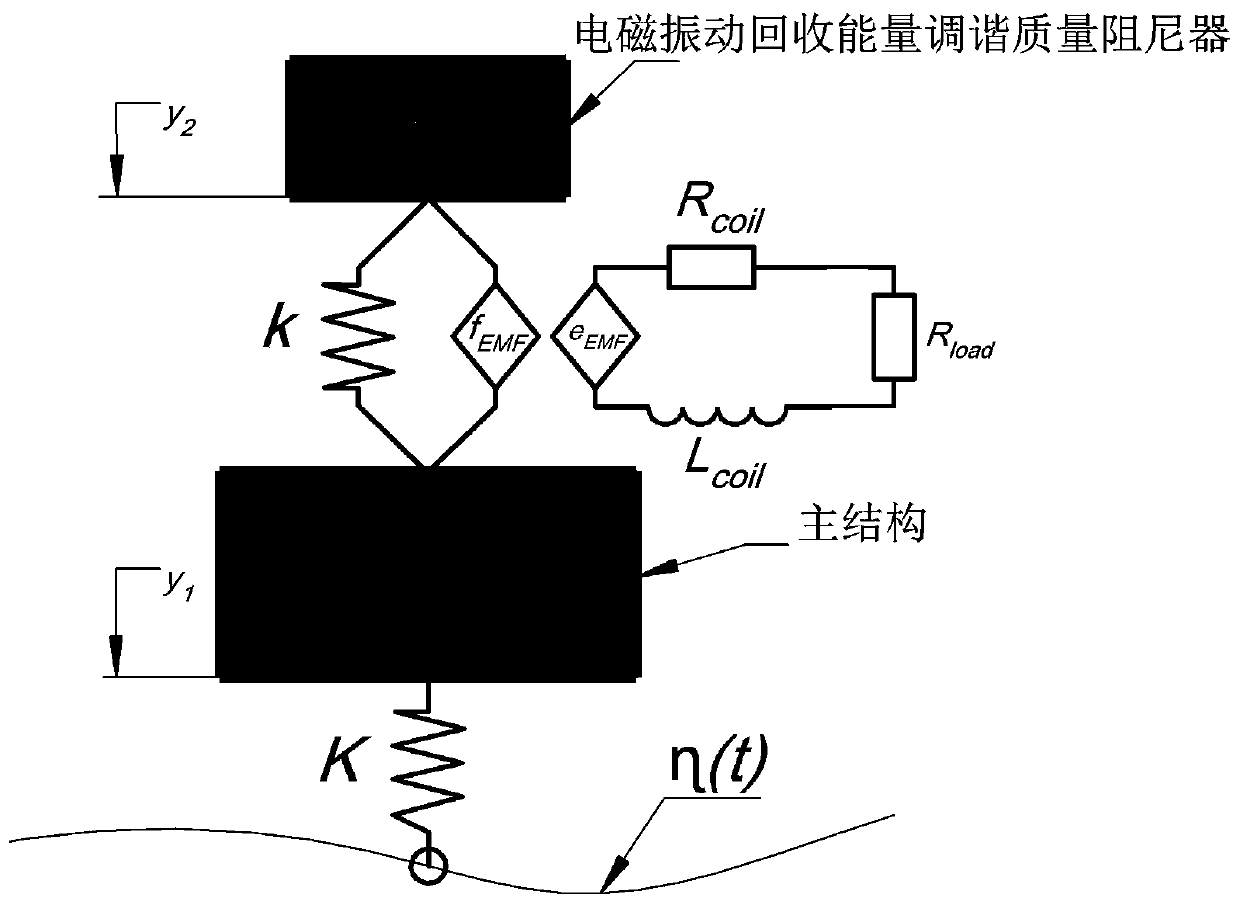

[0040] Take a main structure with a mass of 40 kg and a stiffness of 157,880 N / m as an example, which is exposed to harmonic vibrations with an amplitude of 0.005 m and a frequency of 62.8 rad / s, which is equal to the natural frequency of the structure. To protect this structure from damage, the electromagnetic vibration recovery energy tuned mass damper of the present invention is used. According to the optimal theoretical vibration suppression effect of the tuned mass damper, the structural parameters of the tuned mass damper selected in this embodiment are as follows: the mass is 8 kg, the stiffness is 21752 N / m, and the damping parameter is 219 N*sec / m.

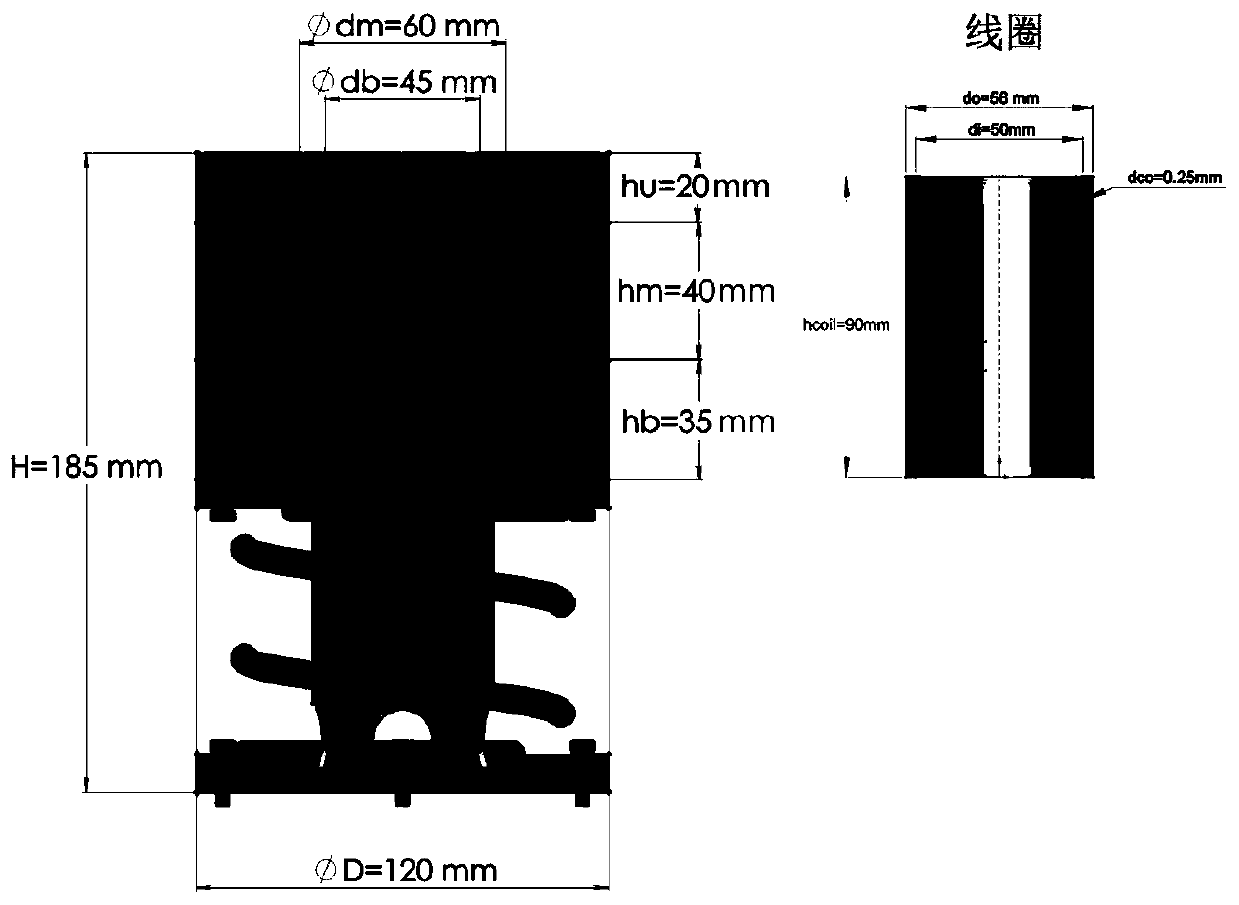

[0041] Because the rare earth permanent magnet material FeNdB grade N52 has high residual magnetic flux density and economy, it is selected as the material of the ring magnet assembly. The material of the bottom ferromagnet and the upper ferromagnet is selected from low carbon steel 1010, which has a comparable magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com